High concentration desulfurization organic pharmaceutical wastewater treatment equipment

A technology for pharmaceutical wastewater and treatment equipment, applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve problems such as shortened life, increased workload, and filter head corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

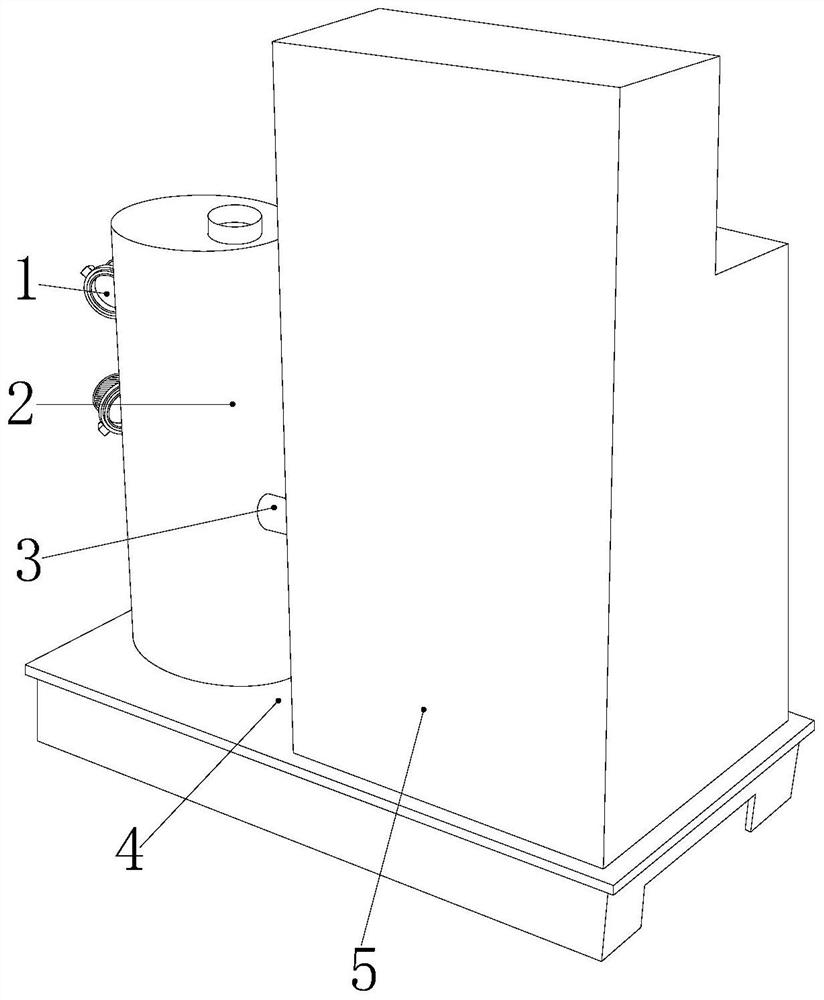

[0026] see Figure 1-Figure 3 , the present invention provides high-concentration desulfurization organic pharmaceutical wastewater treatment equipment, its structure includes a filter device 1, a filter chamber 2, a connecting pipe 3, a base 4, and a treatment chamber 5, the filter device 1 is installed in the filter chamber 2, the The filter chamber 2 communicates with the connecting pipe 3, and the filter chamber 2 is connected with the processing chamber 5 through the connecting pipe 3, and the processing chamber 5 and the filter chamber 2 are both fixed on the base 4.

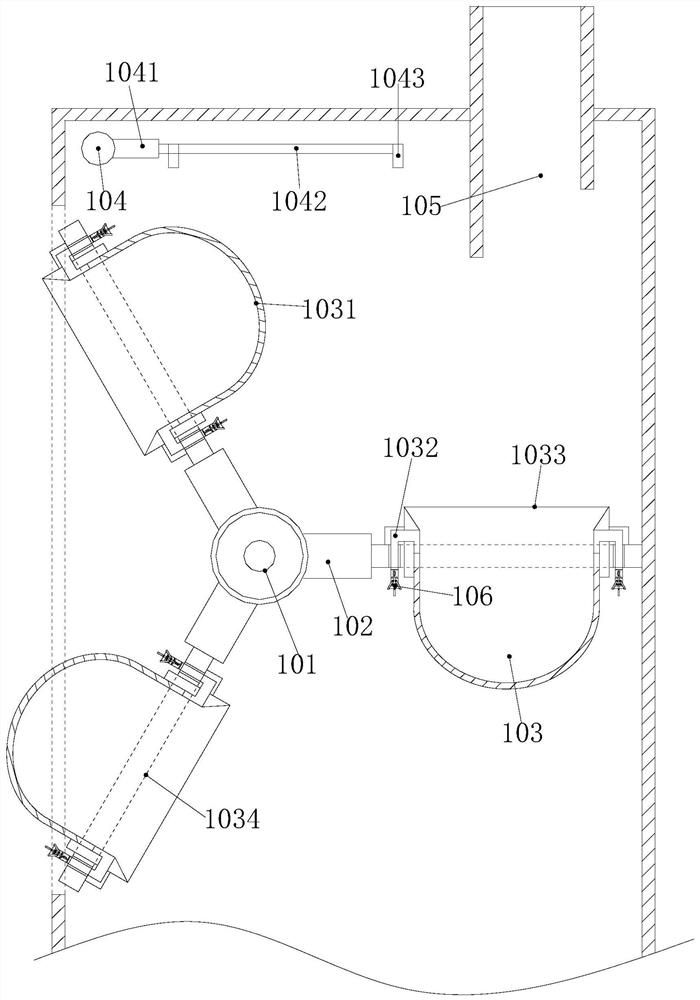

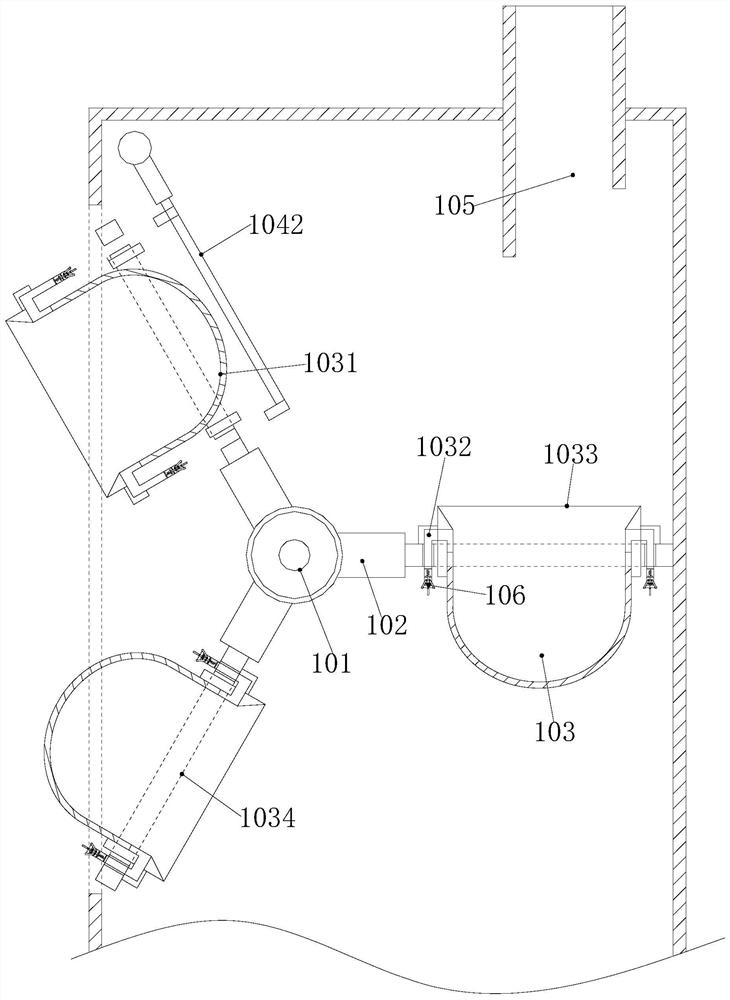

[0027] The filter device 1 is composed of a main shaft 101, a fixed connection column 102, a filter head 103, a beating mechanism 104, a waste water inlet pipe 105, and a lever mechanism 106. The main shaft 101 and the fixed connection column 102 are mechanically welded. The fixed connection column 102 is fixedly connected with the filter head 103, the filter head 103 is provided with three, the number of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com