A nozzle adjustment mechanism

A technology for adjusting mechanisms and nozzles, which is applied in the manufacture of tools, abrasives, metal processing equipment, etc., can solve the problems of inability to automatically adjust the distance of the nozzle, the inability to change the angle of the nozzle, and the complexity of the fixed structure, so as to ensure the stability of the nozzle and improve the quality of the nozzle. The effect of spray processing quality and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

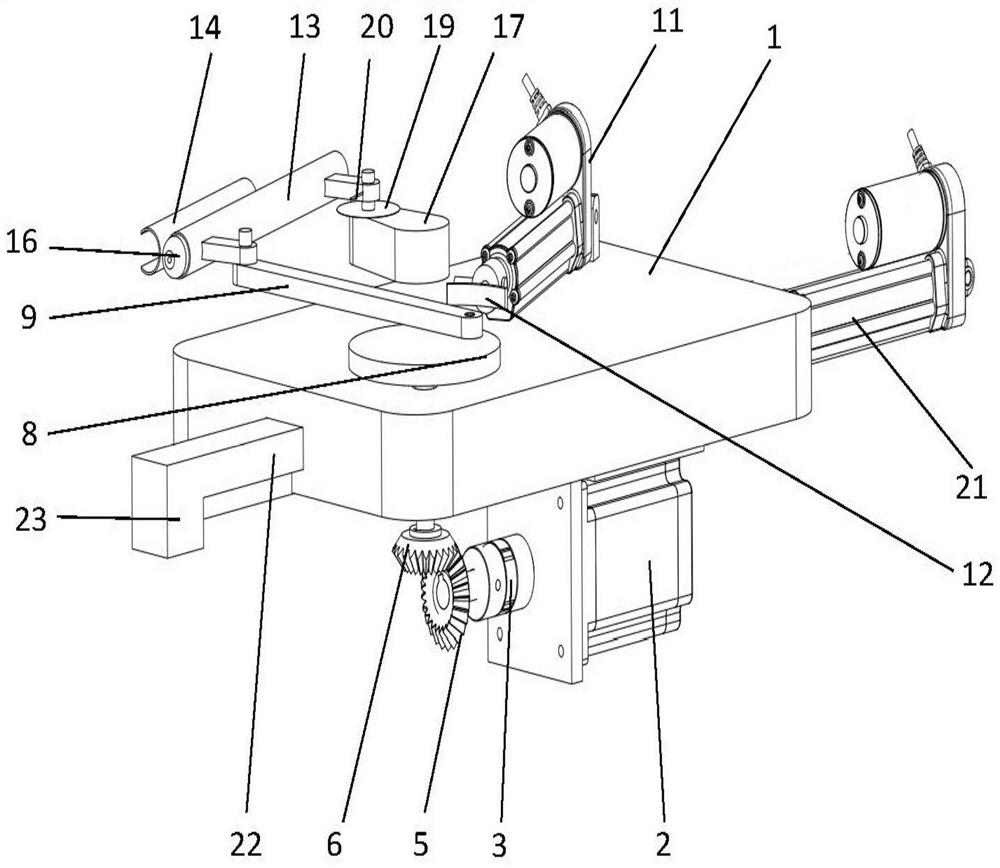

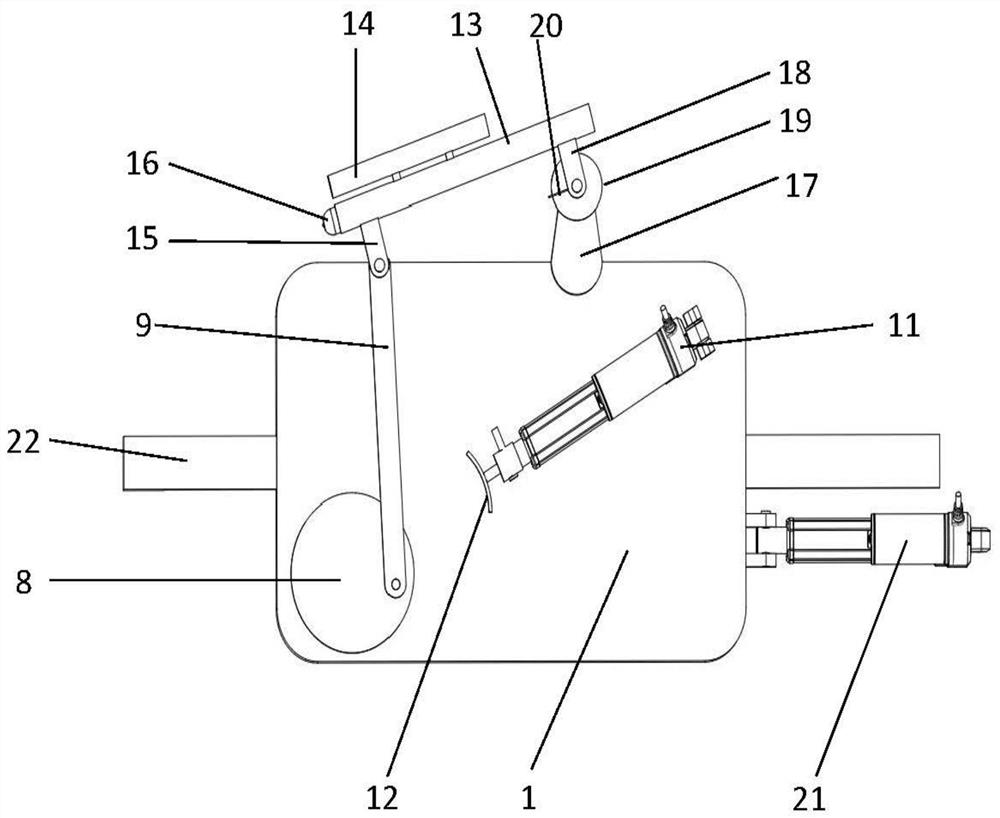

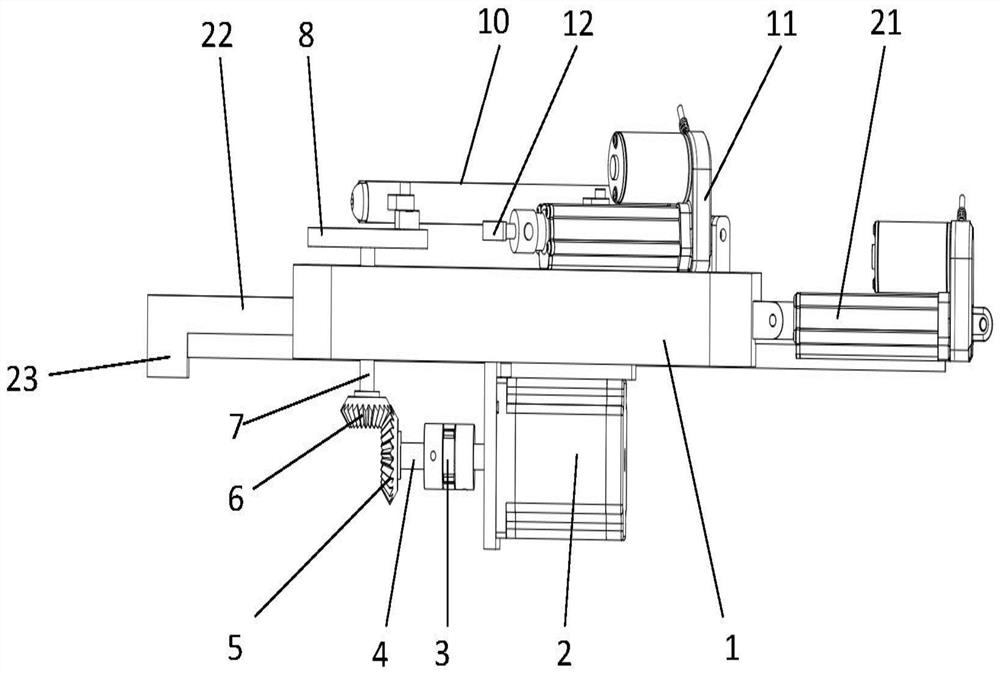

[0022] The present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments.

[0023] In order to facilitate a unified review of the various reference signs in the drawings of the specification, the unified description of the reference signs appearing in the drawings of the specification is as follows:

[0024] 1 is the bottom plate, 2 is the motor, 3 is the coupling, 4 is the first straight shaft, 5 is the first bevel gear, 6 is the second bevel gear, 7 is the second straight shaft, 8 is the turntable, and 9 is the connecting rod , 10 is the nozzle assembly, 11 is the first electric push rod, 12 is the friction plate, 13 is the round tube, 14 is the nozzle sleeve, 15 is the first connecting piece, 16 is the laser pointer, 17 is the boss, 18 is the second Two connecting pieces, 19 is a dial, 20 is a pointer, 21 is a second electric push rod, 22 is a fixed guide rail, and 23 is a limit block.

[0025] combine figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com