Crawler type traffic movement tool

A kind of traffic movement, crawler technology, applied in the direction of crawler vehicles, motor vehicles, electric vehicles, etc., can solve the problems of high power consumption, easy damage of transmission parts, and increased production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

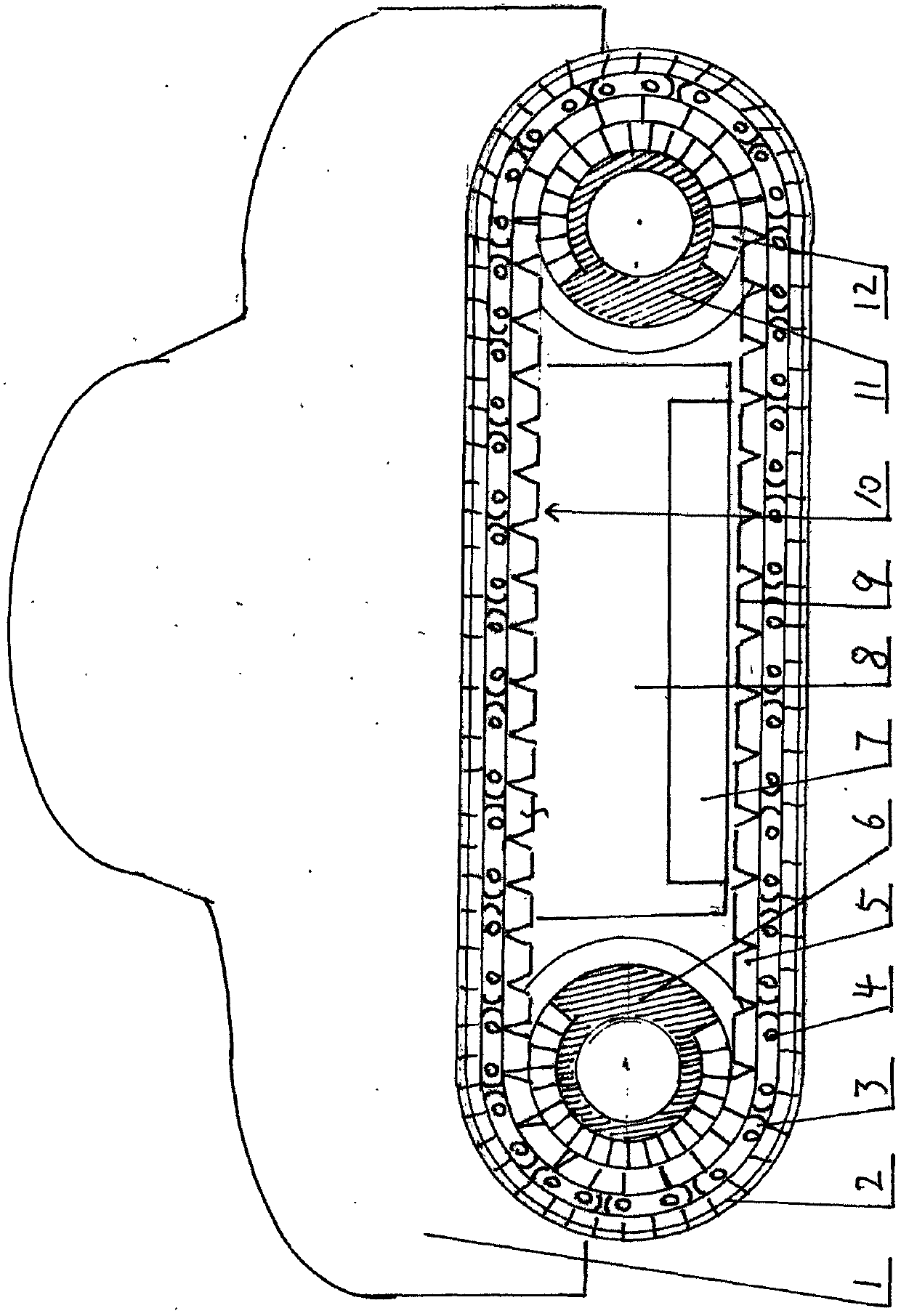

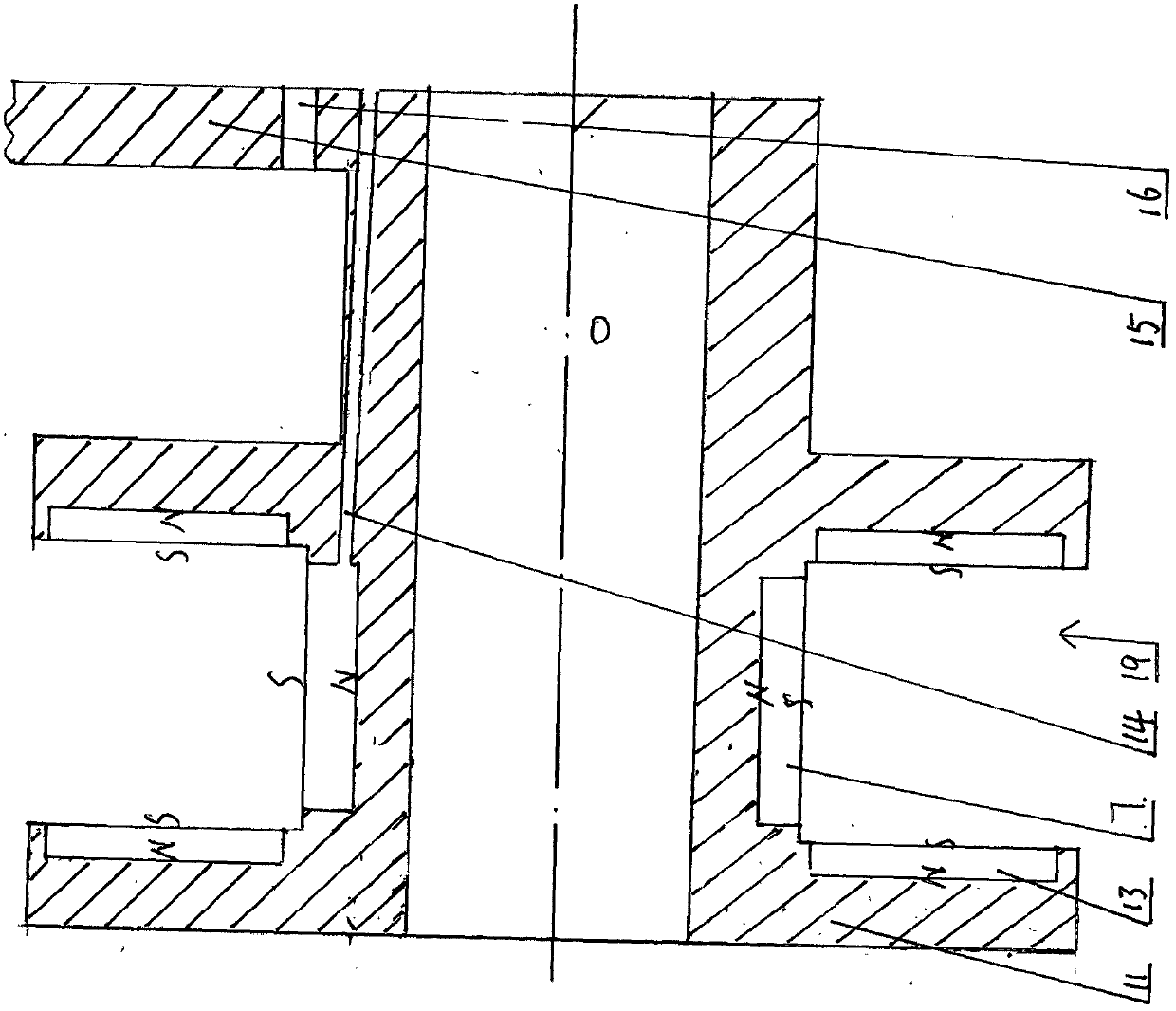

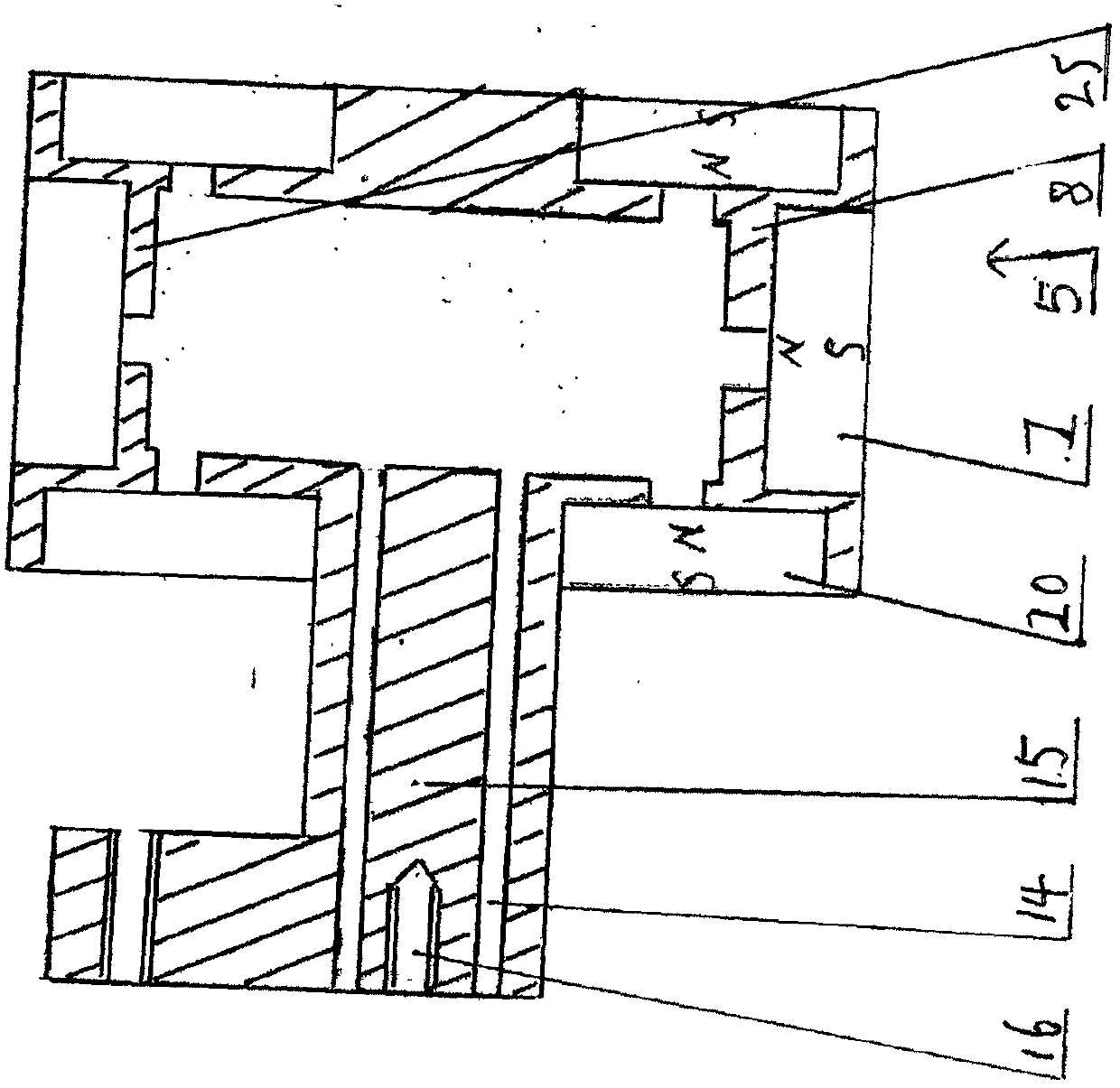

[0114] A tracked vehicle, such as Figure 1-Figure 3 , Figure 5 , Figure 6 , Figure 7 As shown, the crawler vehicle 1 of the first embodiment of the present invention, the present invention implements the technology of the magnetic levitation track on the automobile 1, and the crawler vehicle of the present invention is integrated or connected on the crawler vehicle And form an electromagnetic wheel 11 integrally, the electromagnetic wheel 11 is provided with a wire conduit 14, the electromagnetic wheel 11 is provided with a drive magnetic field 12 (S / N), and the magnetic levitation positioner 8 is integrally or connected and formed into an integrally set bearing The magnetic field 7 (S / N), integrally or connected and formed integrally to set the positioning magnetic field 13 (S / N) or the orientation magnetic field 20 (S / N), integrally or on the crawler belt 3 with the magnetic field (S / N) The levitation magnetic field 10 (S / N) is connected and formed integrally, the pos...

Embodiment approach 2

[0135] A tracked vehicle, such as Figure 4 As shown, the crawler vehicle 1 of the second embodiment of the present invention, on the basis of the first embodiment, the present invention implements the technology of the magnetic levitation track on the tank 17, and the crawler vehicle of the present invention is through the crawler The electromagnetic wheel 11 is arranged on the type transportation tool, and the electromagnetic wheel 11 is provided with a wire conduit 14, and the drive magnetic field 12 (S / N) is set integrally or connected and formed as one, and the magnetic levitation positioner 8 is integrally or connected and formed as The load-bearing magnetic field 7 (S / N) is set integrally, the positioning magnetic field 13 (S / N) is set integrally or connected and formed integrally, and the levitation magnetic field 10 is set integrally or connected and formed integrally on the crawler belt 3 with magnetic field (S / N), integrated or connected and formed as one to set the...

Embodiment approach 3

[0151] A tracked vehicle, such as Figure 5 , Figure 7 As shown, the crawler-type traffic tool 1 of the third embodiment of the present invention, on the basis of the first-second embodiment, the present invention implements the technology of magnetic levitation front and rear double crawlers on the automobile 1, and the crawler-type traffic movement of the present invention The tool is to set the electromagnetic wheel 11 on the crawler type transportation tool, the electromagnetic wheel 11 is provided with a wire conduit 14, the driving magnetic field 12 (S / N), the gliding magnetic field 7 (S / N) is set on the magnetic levitation device 8, and the positioning magnetic field 13 (S / N), the track adjuster 25 is set on the magnetic levitation positioner 8, the levitation magnetic field 10 (S / N) is set on the track belt 3 with magnetic field, the positioning magnetic field 13 (S / N), and the positioning magnetic slot is set on the electromagnetic wheel 11 19 (if figure 2 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com