Backlight unit and light-emitting module of spliced module lamp box

A backlight unit and light-emitting module technology, which is applied to display devices, illuminated signs, instruments, etc., can solve the problems of dark shadows in cabinets and the inability to realize shadowless splicing, and achieve the effects of easy maintenance, simple structure, and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solution in the embodiment of the present invention will be clearly and completely described below in conjunction with the description of drawings in a modular light box embodiment of the present invention.

[0028] The front side and the rear side described in this embodiment are based on the directions shown in the description of the drawings.

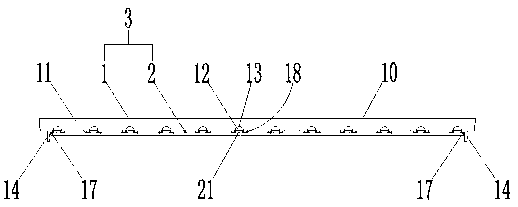

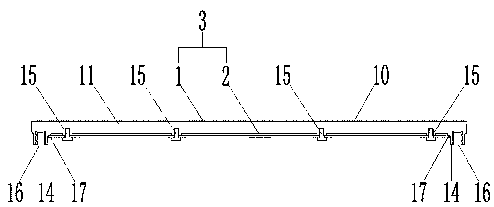

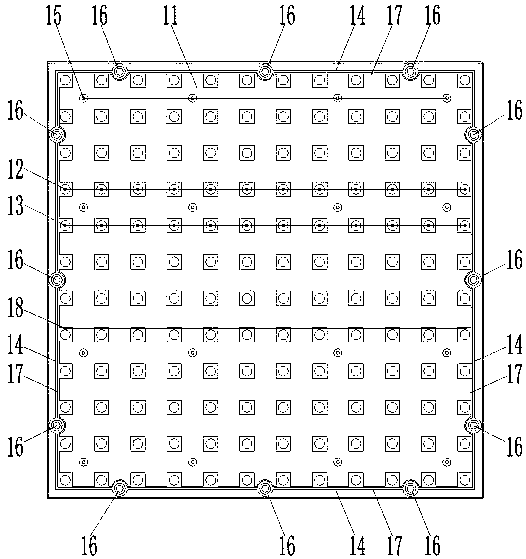

[0029] Embodiments of the backlight unit of the assembled modular light box of the present invention, such as Figure 1 to Figure 4As shown, the backlight unit 3 is composed of an integrated lens module 1 and a light source module 2 installed together with the light source module. The above-mentioned integrated lens module 1 is composed of a lens substrate 11, a plurality of light entrances 12 evenly distributed in an array on the rear side of the lens substrate 11, a concave spherical surface 13 at the bottom of the light entrance 12, and a lens set on the rear side of the lens substrate 11. The integrated lens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com