Speed regulation motor

A speed-regulating motor and speed-regulating technology, applied in the shape/style/structure of winding conductors, can solve the problems of low starting torque, difficult motor wiring, low efficiency in low gear, etc., to reduce temperature rise and improve low gear work. Efficiency and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

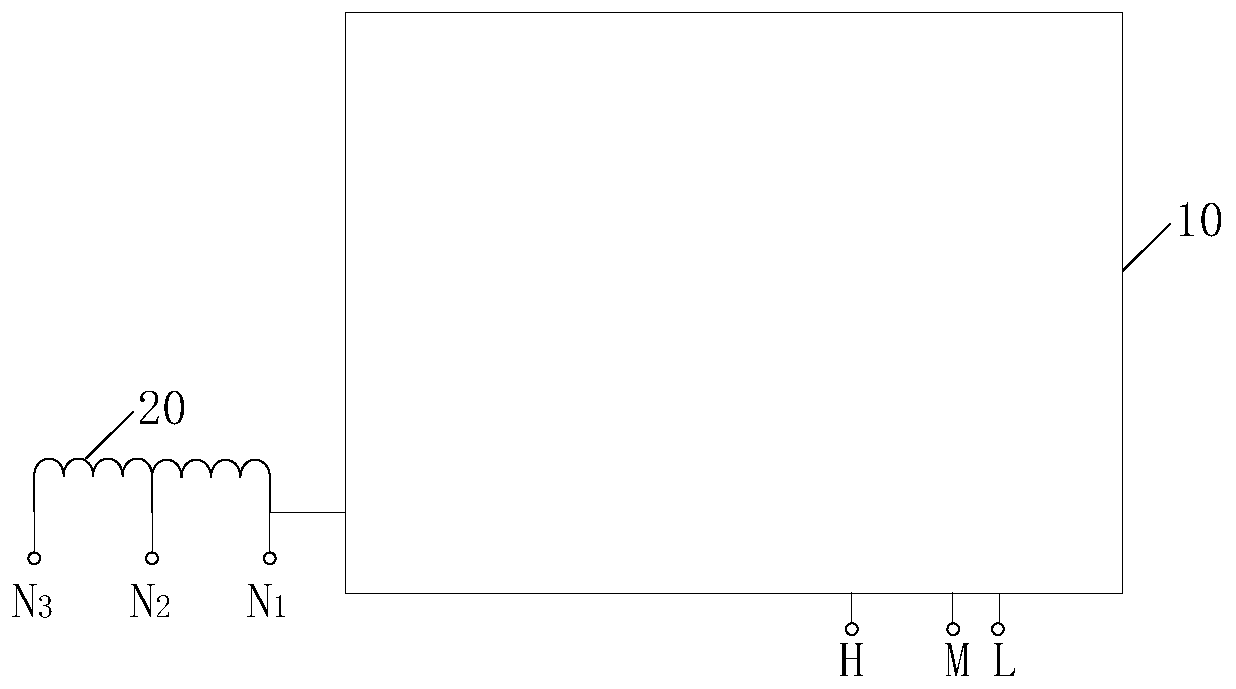

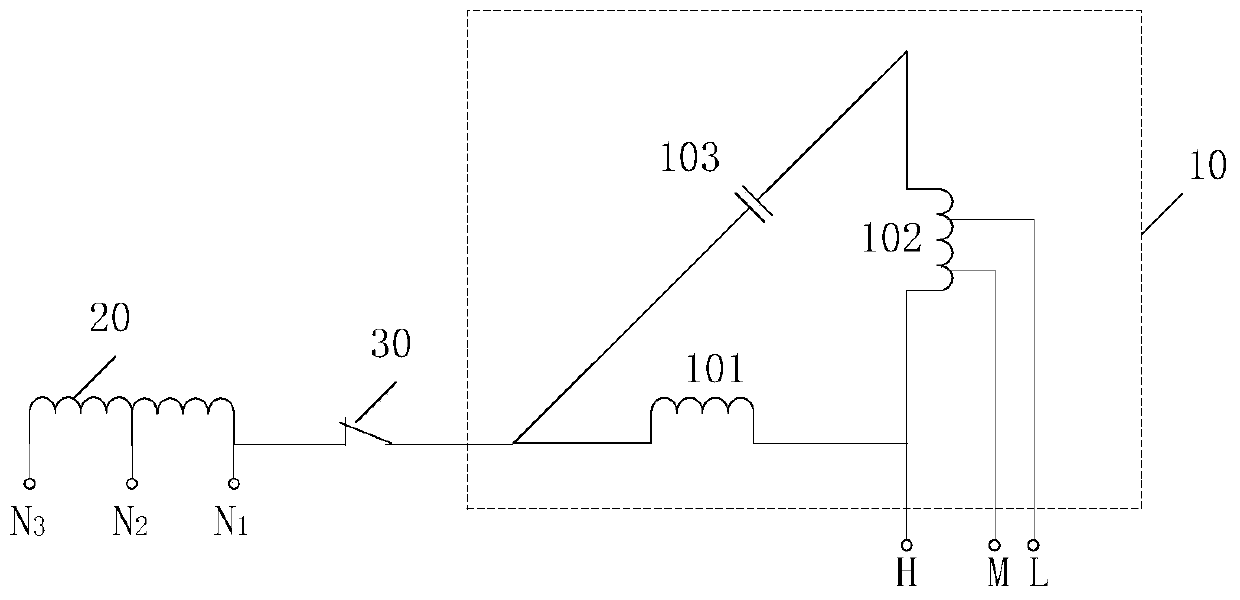

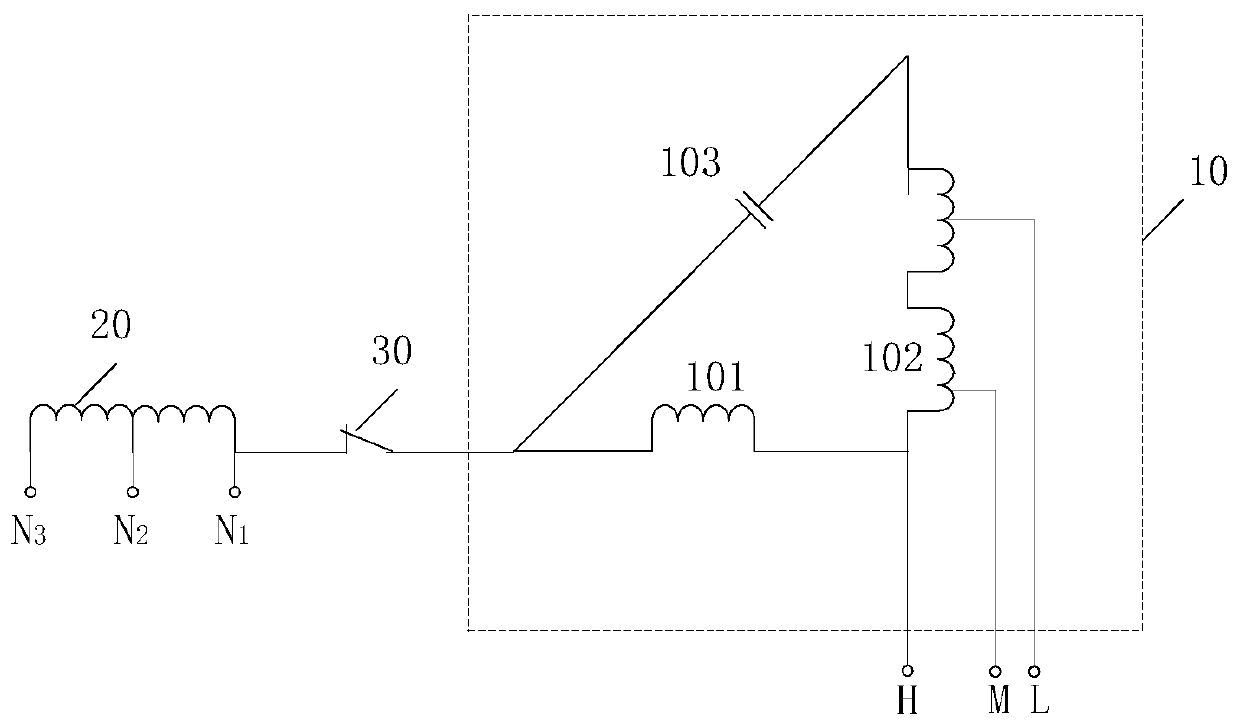

[0023] The present invention will be further described below in combination with specific embodiments. Among them, the accompanying drawings are only for illustrative purposes, showing only schematic diagrams, rather than actual drawings, and should not be understood as limitations on this patent; for those skilled in the art, some known structures and their descriptions in the accompanying drawings may be omitted. understandable.

[0024] In the description of the present invention, it should be understood that if the orientation or positional relationship indicated by the terms "upper", "lower", "left", "right", "inner" and "outer" are based on the drawings The orientations or positional relationships shown are only for the convenience of describing the present invention and simplifying the description, and do not indicate or imply that the referred devices or elements must have a specific orientation, be constructed and operated in a specific orientation, so the positional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com