Tool cathode provided with variable inner cavity and used for carrying out electrolytic machining on integrated blade disc with large-distortion blades

A technology of integral blisks and twisted blades, which is applied in the direction of processing electrodes, electric processing equipment, and the supply of processing working media, etc., can solve the problem of difficult machining of large twisted and variable-section integral blisks, uneven distribution of blade finishing allowances, and inability to Process blisk blades and other issues to achieve the effect of uniform distribution of machining allowance, reduction of leveling allowance, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical means, implementation schemes, objectives and beneficial effects of the present invention easy to understand, further explanations will be given below in conjunction with the accompanying drawings.

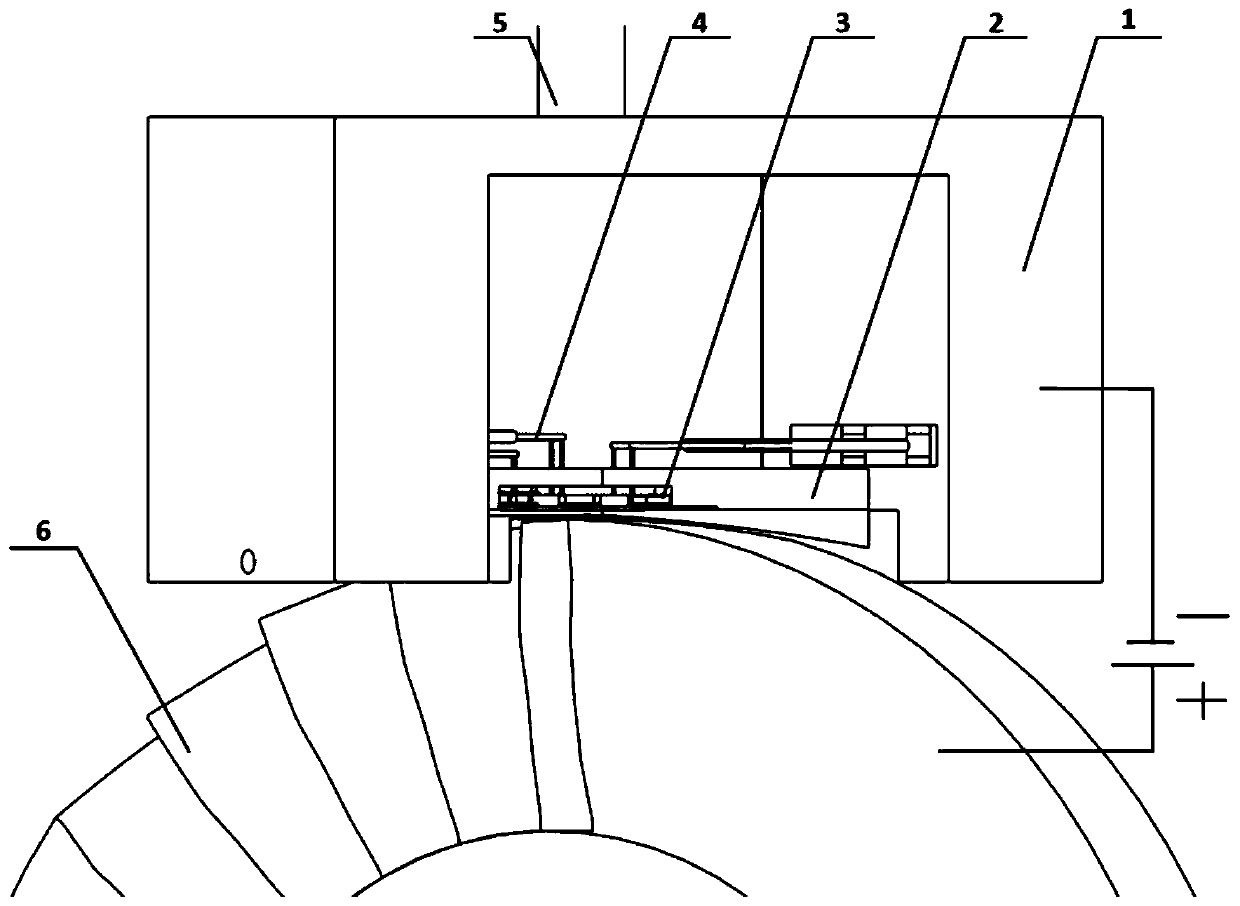

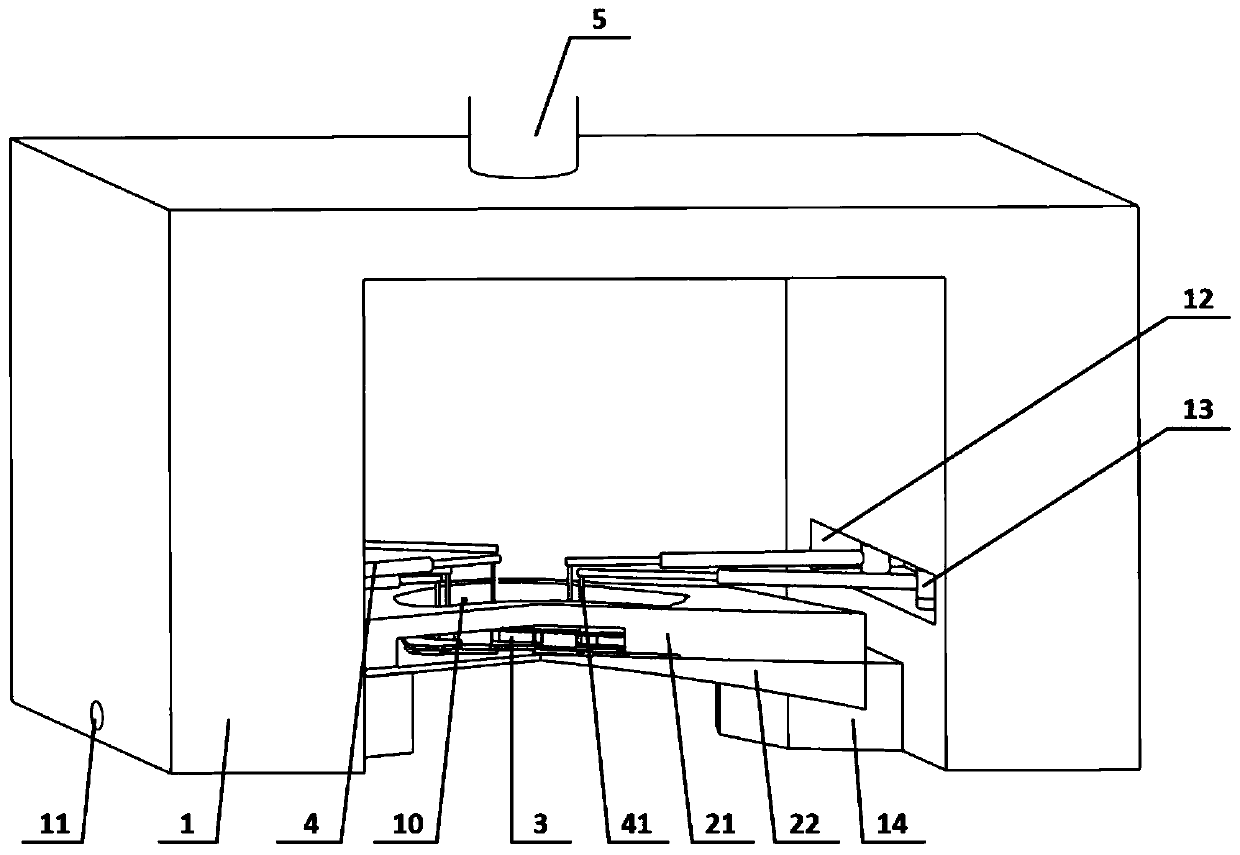

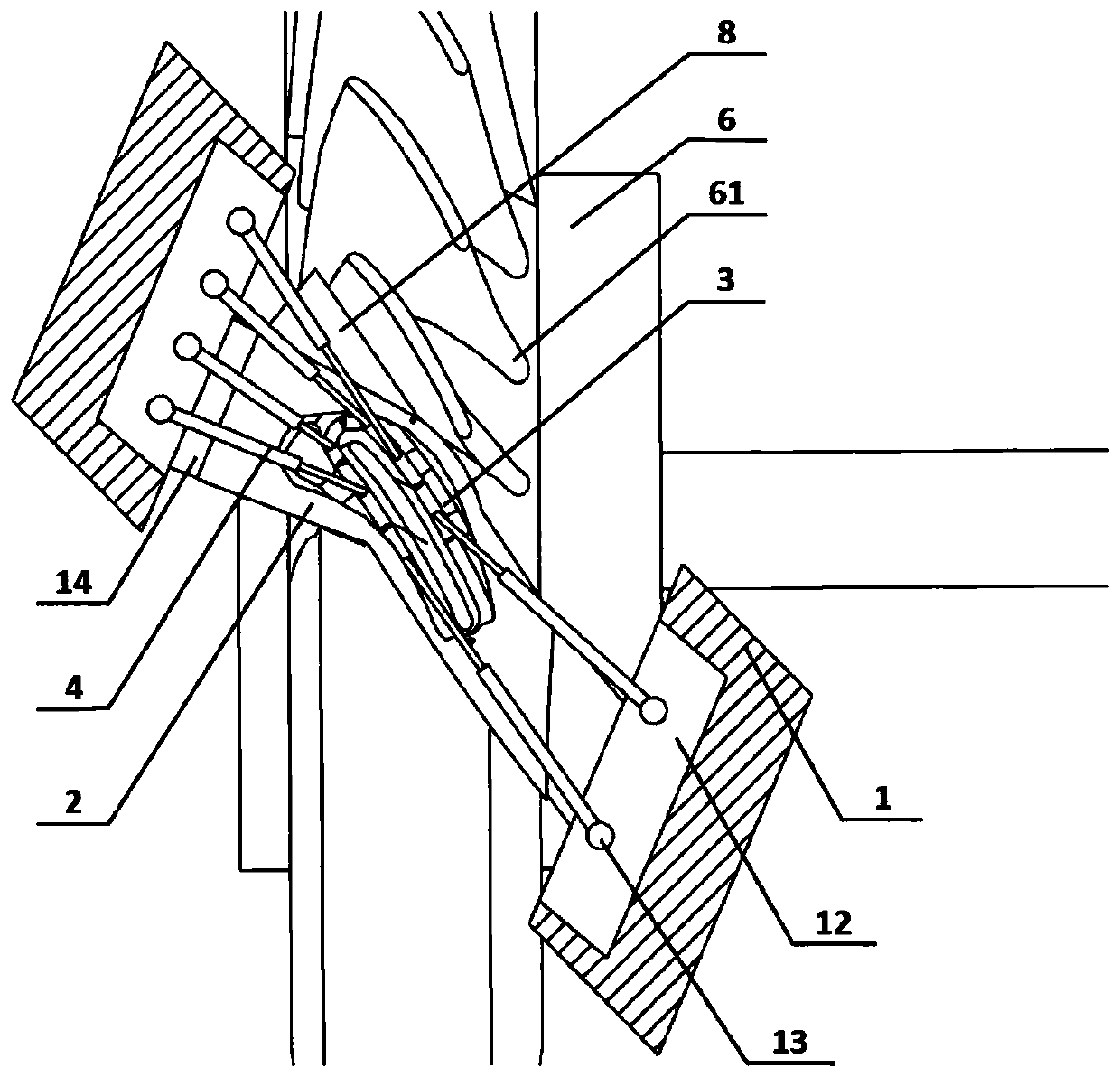

[0032] Such as figure 1 As shown in -7, the cathode of a variable inner cavity tool for electrolytic processing of large twisted blade integral blisks according to the present invention, the device includes a cathode clamp 1, a cathode casing 2, a cathode connecting rod 3, an electric push rod 4, and a clamp Drive shaft 5, blisk 6, etc.; one end of the fixture drive shaft 5 is fixedly installed on the machine tool, and the other end is connected to the cathode fixture 1 in rotation; electrolyte inlet 11 and a rotatable base are provided on both sides of the cathode fixture 1 Slot 12; said rotatable base slot 12 is provided with several rotatable bases 13, and rotatable base 13 built-in motor; described rotatable base 13 is equipped with electr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com