Device for automatic overturning, welding and clamping side wall of high-speed train body and working method thereof

A technology of high-speed trains and welding fixtures, applied in welding equipment, auxiliary devices, auxiliary welding equipment, etc., can solve problems such as additional deformation, weld cracking, and low work efficiency, and achieve reduced risks, improved reliability, and high efficiency , The effect of reducing transfer time and fixture cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

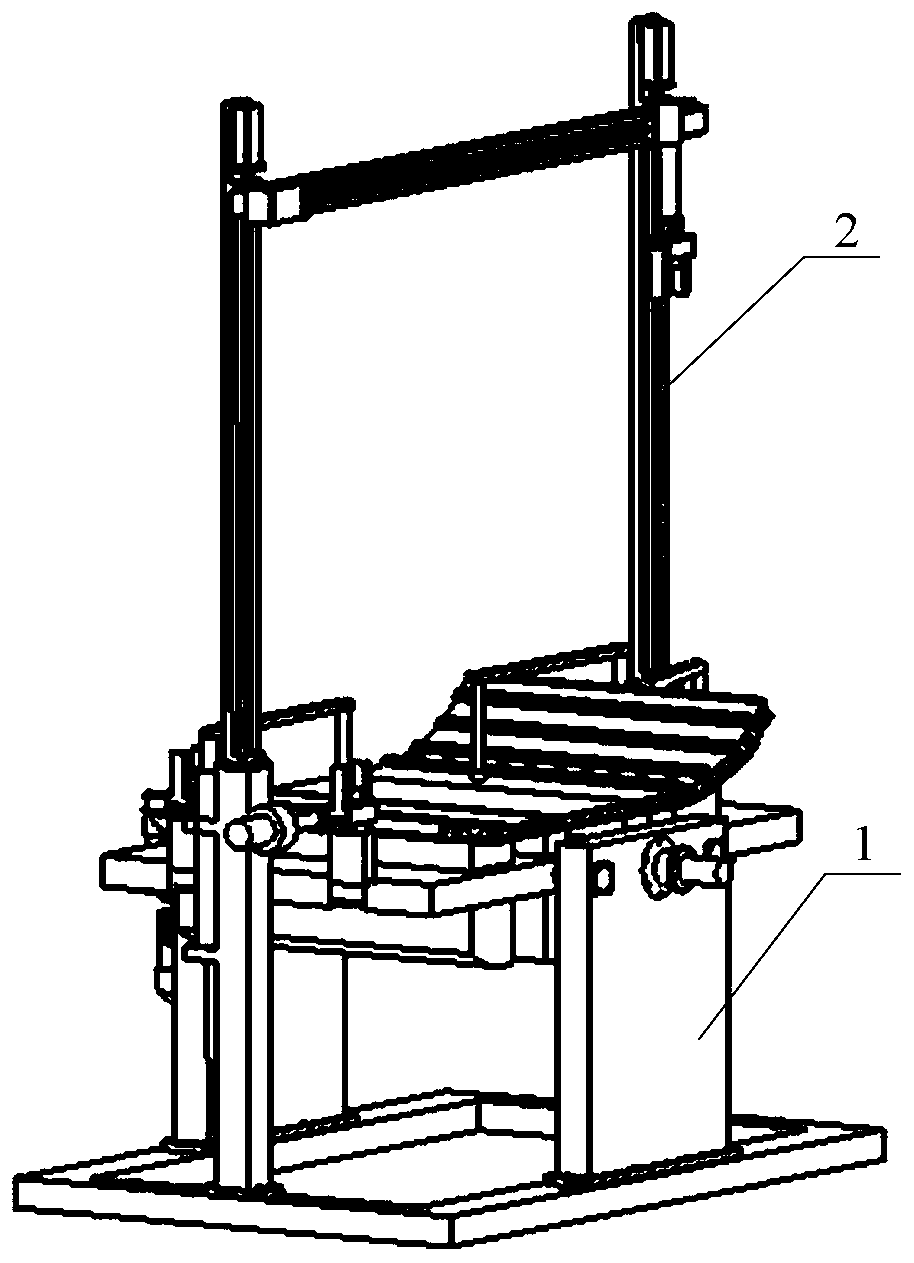

[0067] A high-speed train car body side wall automatic flip welding fixture device, such as figure 1 As shown, it includes an overturning fixture device 1 and an overturning lifting device 2 .

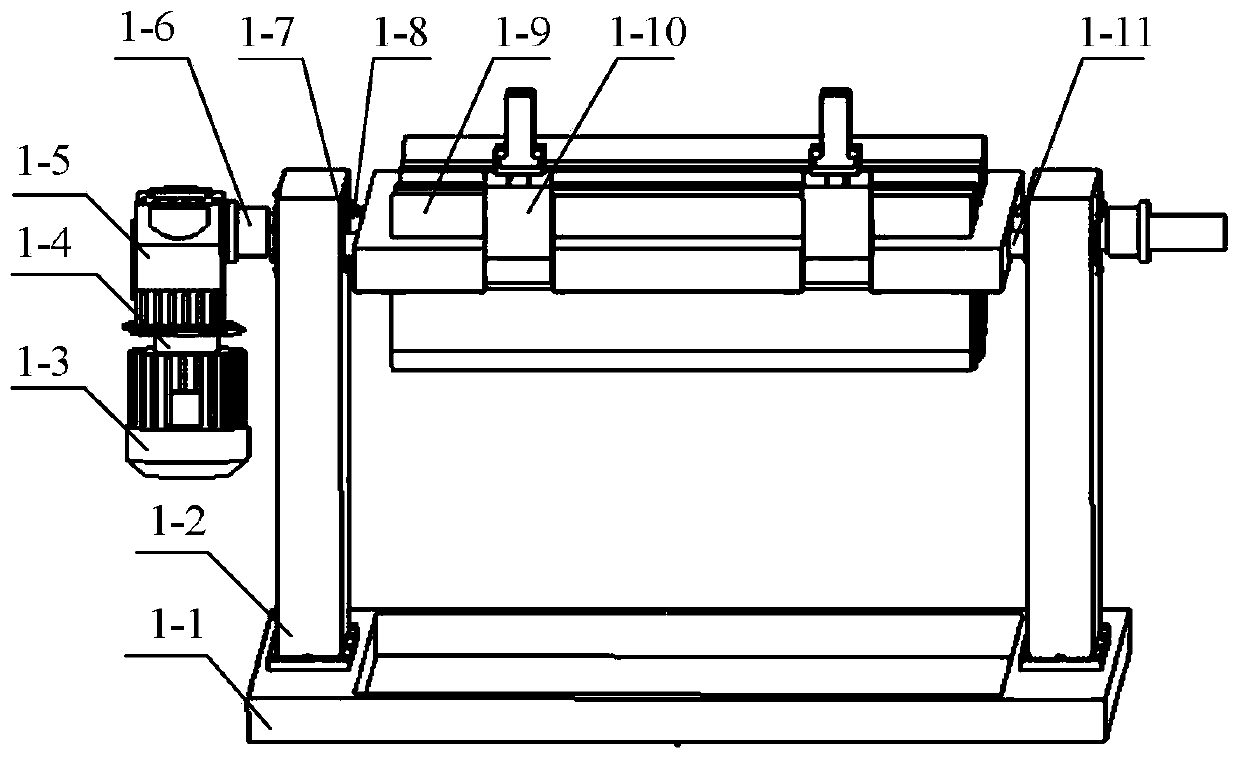

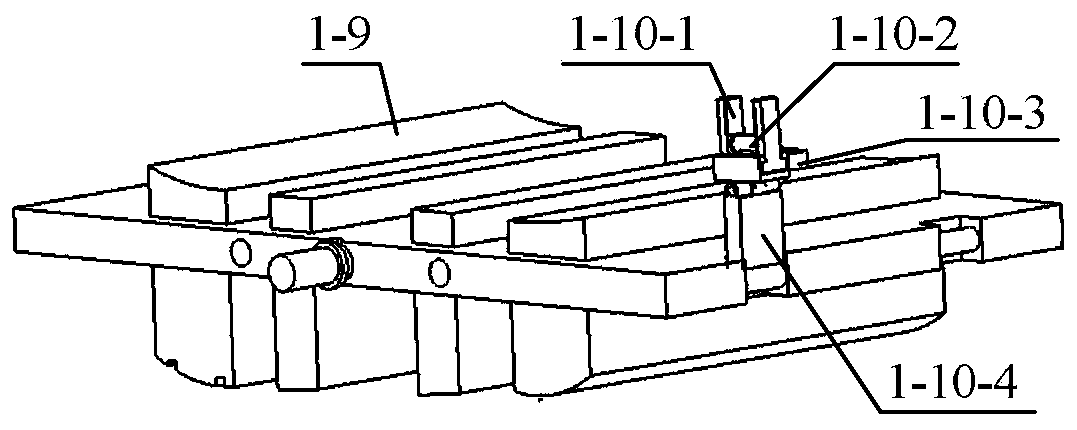

[0068] Turning fixture device 1 comprises underframe 1-1, and underframe is used for providing support for whole overturning fixture device, and underframe is provided with two supports 1-2, and two supports are fixed on the underframe by bolts, and support Between 1-2, there are positive and negative fixtures 1-9, and the positive and negative fixtures 1-9 include fixed blocks that are fixedly connected. The processed positioning surface, the fixed block is used to bear the side wall of the car body, and the front and back sides are positioned when the side wall is welded. One end of the support 1-2 is provided with a motor 1-3, the motor is connected with the positive and negative clamps, and the motor is used to control the flipping of the positive and negative clamps; one end of t...

Embodiment 2

[0075] A high-speed train car body side wall automatic flip welding jig device, its structure is as described in embodiment 1, the difference is that one end of the support 1-2 is also provided with a turbine reducer 1-5, such as figure 2 As shown, the motor 1-3 is connected to the worm reducer 1-5 through the coupling A 1-4, and the worm reducer 1-5 is connected to the positive and negative clamp shaft through the coupling B 1-6, and one end of the positive and negative clamp shaft is The bearing 1-7 is connected with the support 1-2, and the other end of the rotating shaft of the positive and negative clamp is connected with another support through the bearing.

Embodiment 3

[0077] A high-speed train car body side wall automatic flip welding jig device, its structure is as described in Embodiment 2, the difference is that the support 1-2 is provided with a horizontal support cylinder 1-11, and the positive and negative clamp sides are provided with positioning The hole is located in the positioning hole after the piston rod of the horizontal support cylinder stretches out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com