Woven fabric

A fabric and fiber technology, applied in the types of packaging items, special packaging items, animal taming devices, etc., can solve the problems of non-disclosure, etc., and achieve the effects of good compression, reduced bending, and good light guide.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

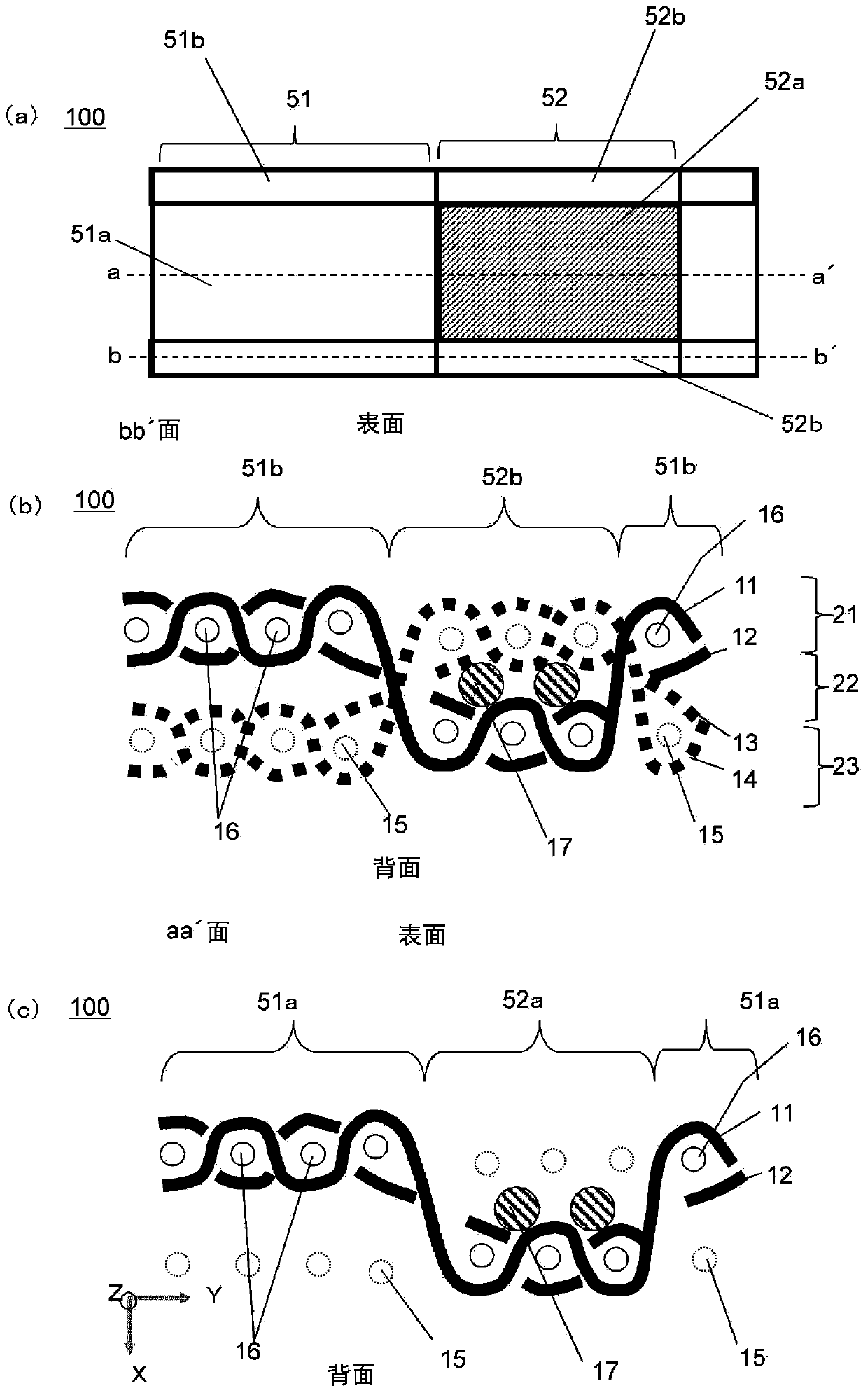

[0117] figure 1 Among them, (a) is a plan view of the fabric 100 of Embodiment 1, (b) is a sectional view of the bb' portion of (a), and (c) is a sectional view of the aa' portion of (a).

[0118]

[0119] Fabric 100 repeats fiber optic region 52 and decorative region 51 . The optical fiber region 52 is a region where the seventh fiber 17 as an optical fiber is braided. The decoration area 51 is an area without optical fibers.

[0120] The fiber region 52 includes a fixed region 52b and a light emitting region 52a. Repeat for both areas. In addition, in order to reduce bending and pressure on the seventh fiber 17 as an optical fiber, the fixed region 52b can make the seventh fiber 17 not exposed on the surface when the seventh fiber 17 as an optical fiber is in a state of excellent light guiding property. It hides fixed regions.

[0121] The fixing region 52b is a region where the seventh fiber 17 is fixed.

[0122] The light emitting region 52a is a region that emits ...

Embodiment approach 2

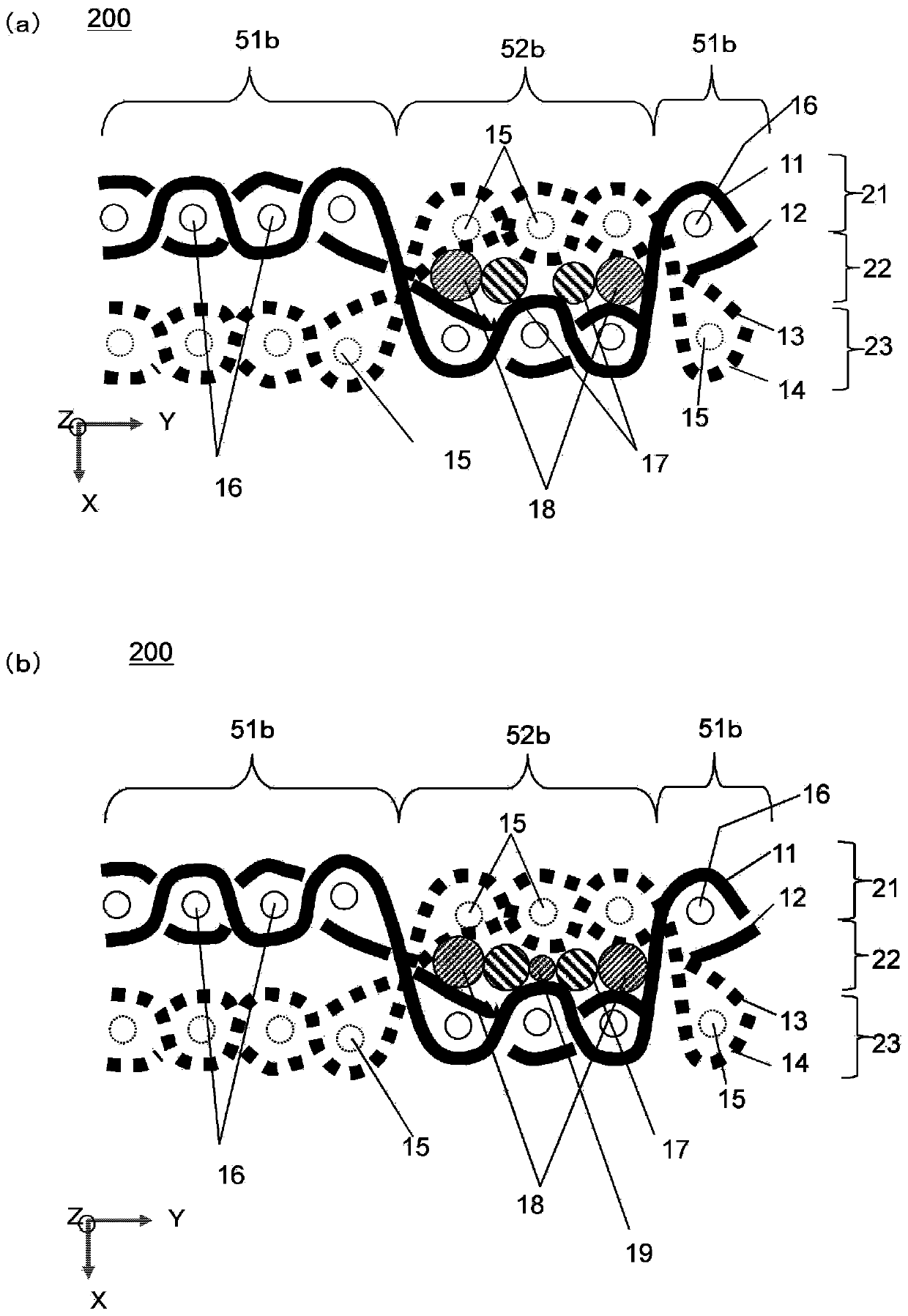

[0168] figure 2 Among them, (a) and (b) are cross-sectional views of the fabric 200 according to the second embodiment. Unlike Embodiment 1, eighth fibers 18 are included. The eighth fiber 18 is a non-optical fiber similarly to the first fiber 11 to sixth fiber 16 . Items not described are the same as those in Embodiment 1. figure 2 (a) and (b) of figure 1 (b), (c) area. Items not described are the same as those in Embodiment 1.

[0169] The seventh fiber 17 (optical fiber) is sandwiched and fixed in the middle layer 22 in the space between the surface layer 21 and the back layer 23 . The eighth fiber 18 is located in the space of the middle layer 22 . The seventh fiber 17 and the eighth fiber 18 are not woven with respect to other fibers, and the seventh fiber 17 (optical fiber) is fixed without hindering linearity. Since the seventh fiber 17 (optical fiber) is not bent, it can emit light efficiently. The eighth fiber 18 also serves to protect the seventh fiber 17 (...

Embodiment approach 3

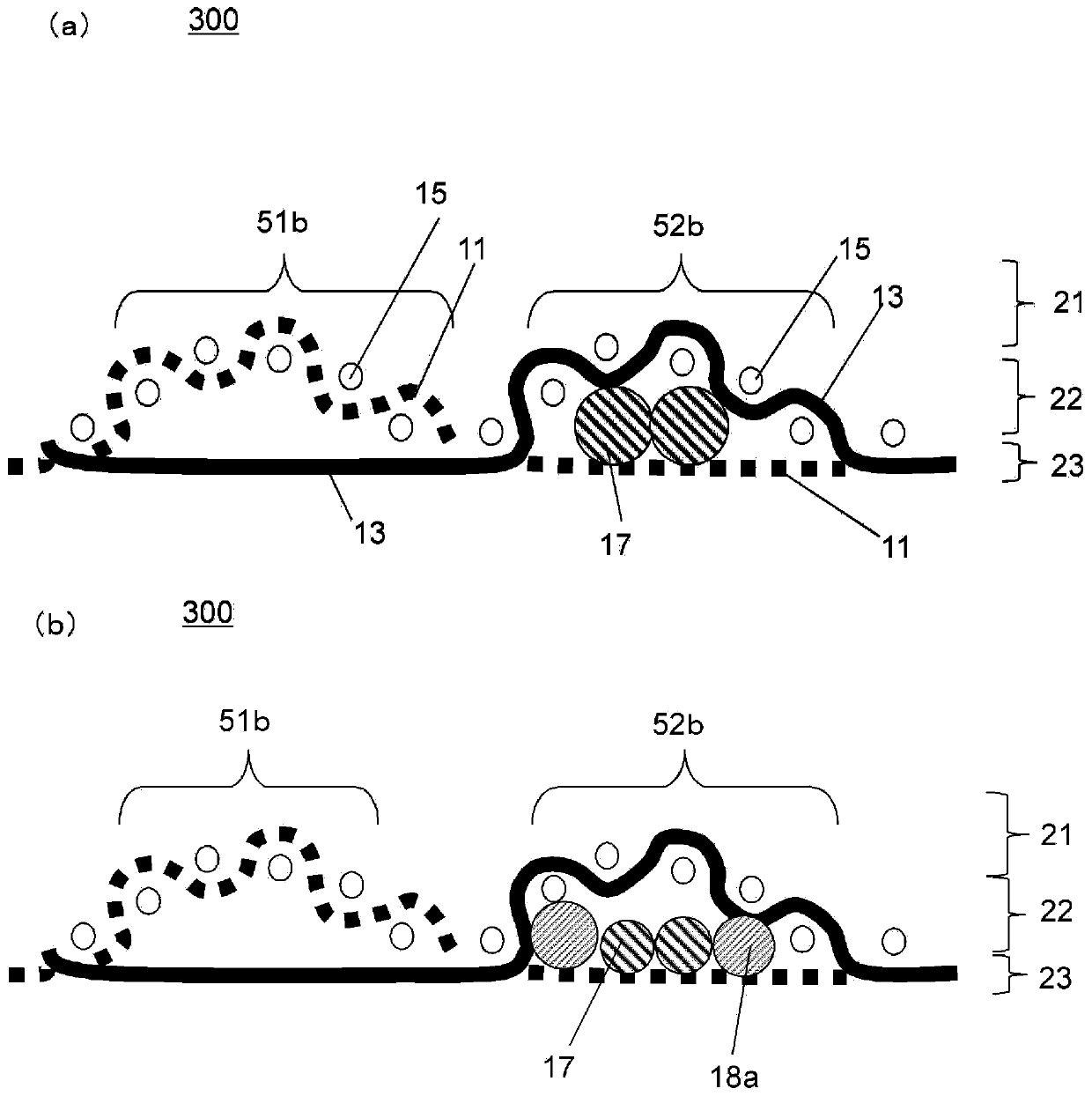

[0179] image 3 Among them, (a) and (b) are cross-sectional views of the fabric 300 according to the third embodiment. Unlike Embodiments 1 and 2, few fibers are used except for the seventh fiber 17 (optical fiber). Items not described are the same as those in Embodiments 1 and 2.

[0180] image 3 Among them, (a) and (b) represent regions corresponding to the fixed region 52b and the second decorative region 51b in the first embodiment.

[0181] In the fixing region 52b, the fifth fiber 15 and the third fiber 13 are woven, and the first fiber 11 is not woven. In the region of the middle layer 22 between the surface layer 21 where the fifth fiber 15 and the third fiber 13 are braided and the first fiber 11 (back layer 23 ), the optical fiber of the seventh fiber 17 is arranged. The region of the intermediate layer 22 is connected in a straight line, and the straightness of the optical fiber of the seventh fiber 17 can be ensured. As a result, the optical fiber can be fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com