Slidable small-resistance embedded railway structure

An embedded track and resistance technology, applied in the field of rail transit, can solve the problem that the rail cannot be stretched vertically, so as to reduce the construction workload and improve the maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

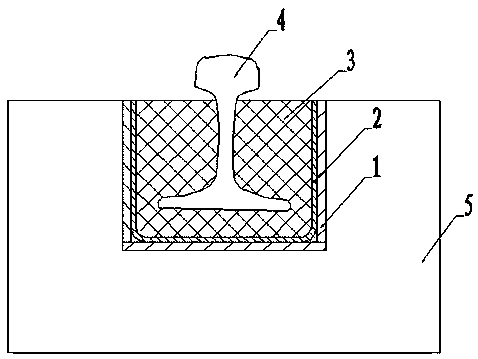

[0028] Such as figure 1 As shown, a slidable low-resistance embedded track structure includes a rail bearing groove 1, a polymer material 3, a steel rail 4, and a track bed plate 5, and an inner groove 2 that can slide longitudinally in the groove is provided in the rail bearing groove 1. , A sliding pair is set between the inner groove 2 and the rail bearing groove 1, and the inner groove 2 is provided with a rail 4 which is locked by a polymer material 3 .

Embodiment 2

[0030] A slidable low-resistance embedded track structure, comprising a rail bearing groove 1, a polymer material 3, a steel rail 4, and a track bed plate 5, an inner groove 2 that can slide longitudinally in the groove is arranged in the rail bearing groove 1, and the inner groove A sliding pair is arranged between 2 and the rail bearing groove 1, and a steel rail 4 is arranged in the inner groove 2 and locked by a polymer material 3. The rail bearing groove 1 is made of steel or fiberglass.

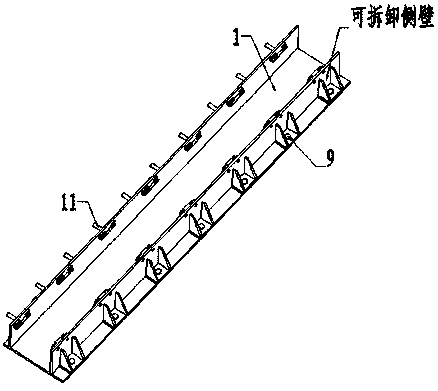

[0031] Such as Figure 2-5 As shown, the rail bearing groove 1 adopts an assembled rail groove, and the assembled rail groove first fixes the bottom plate of the rail groove with bolts 9 or bonding, and then embeds the side wall of the rail groove into the bottom plate of the rail groove. Lateral anchoring structures such as ribs 10 and rivets 11 are arranged on the two outer walls of the rail bearing groove 1 . The cross section of the rail bearing groove 1 is narrow at the top and w...

Embodiment 3

[0034] Such as Figure 6 As shown, a slidable low-resistance embedded track structure includes a rail bearing groove 1, a polymer material 3, a steel rail 4, and a track bed plate 5, and an inner groove 2 that can slide longitudinally in the groove is provided in the rail bearing groove 1. , a sliding pair is set between the inner groove 2 and the rail bearing groove 1, and the steel rail 4 is arranged in the inner groove 2 and locked by the polymer material 3. The rail bearing groove 1 adopts a concrete structure, and its cross section is small at the top and large at the bottom. Eight-shaped, a gap is reserved between the inner groove 2 and the bearing rail groove 1, which is used to fill the rubber backing plate 12, and the inner groove 2 also includes a backing plate, and the polymer material 3 is divided into two parts in the inner groove 2 Two times of pouring, the first time is used to lock the rail 4, and the second time is used as the surface layer material 6 to cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com