Detecting mechanism for rotor embedding grooves of large-medium high-voltage motors

A high-voltage motor and rotor slot technology, applied in the direction of angle/taper measurement, etc., can solve the problems of copper strip tension falling off, difficulty in ensuring accuracy, and workpiece scrapping, etc., to improve work efficiency, ensure success rate, and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

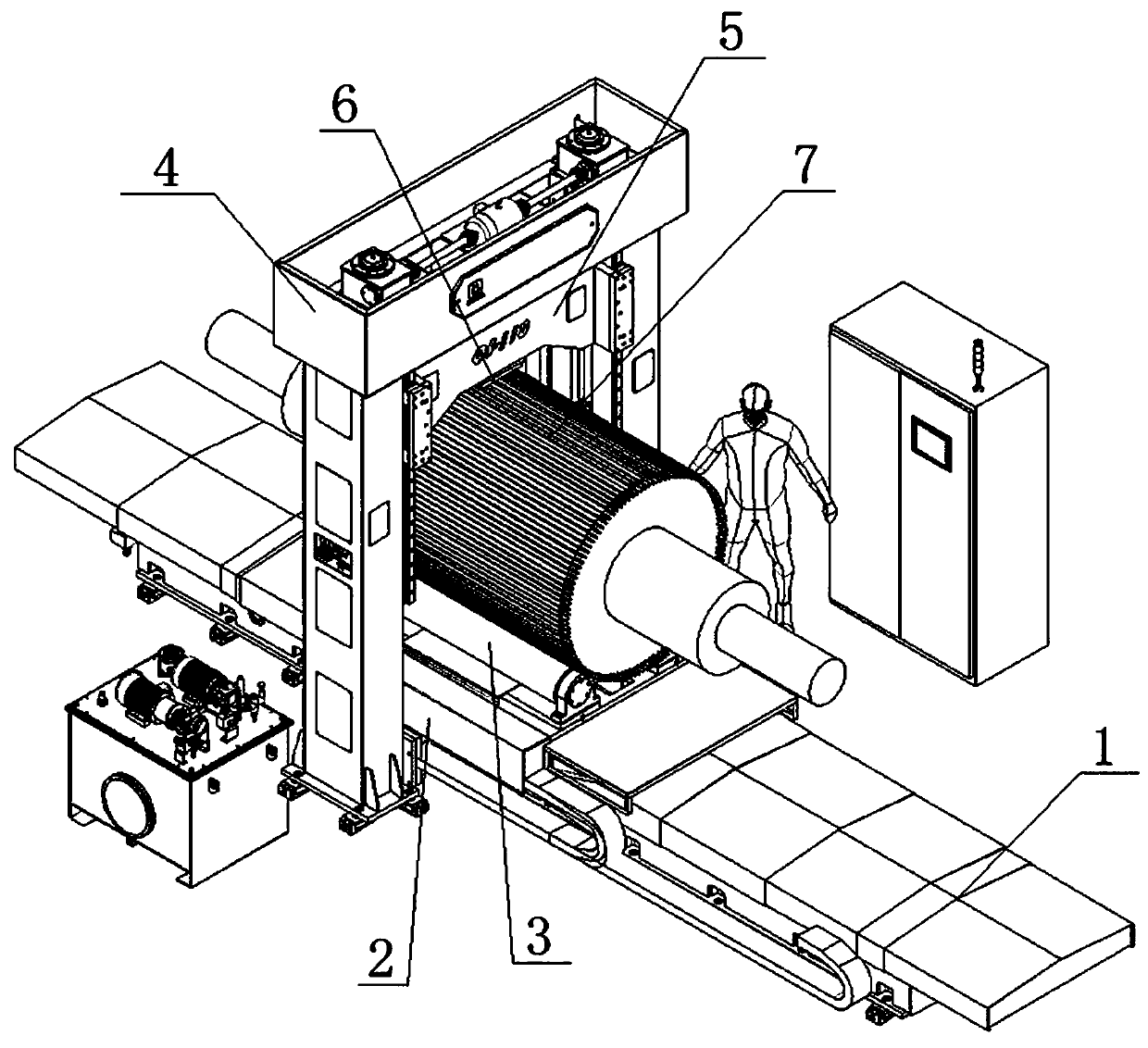

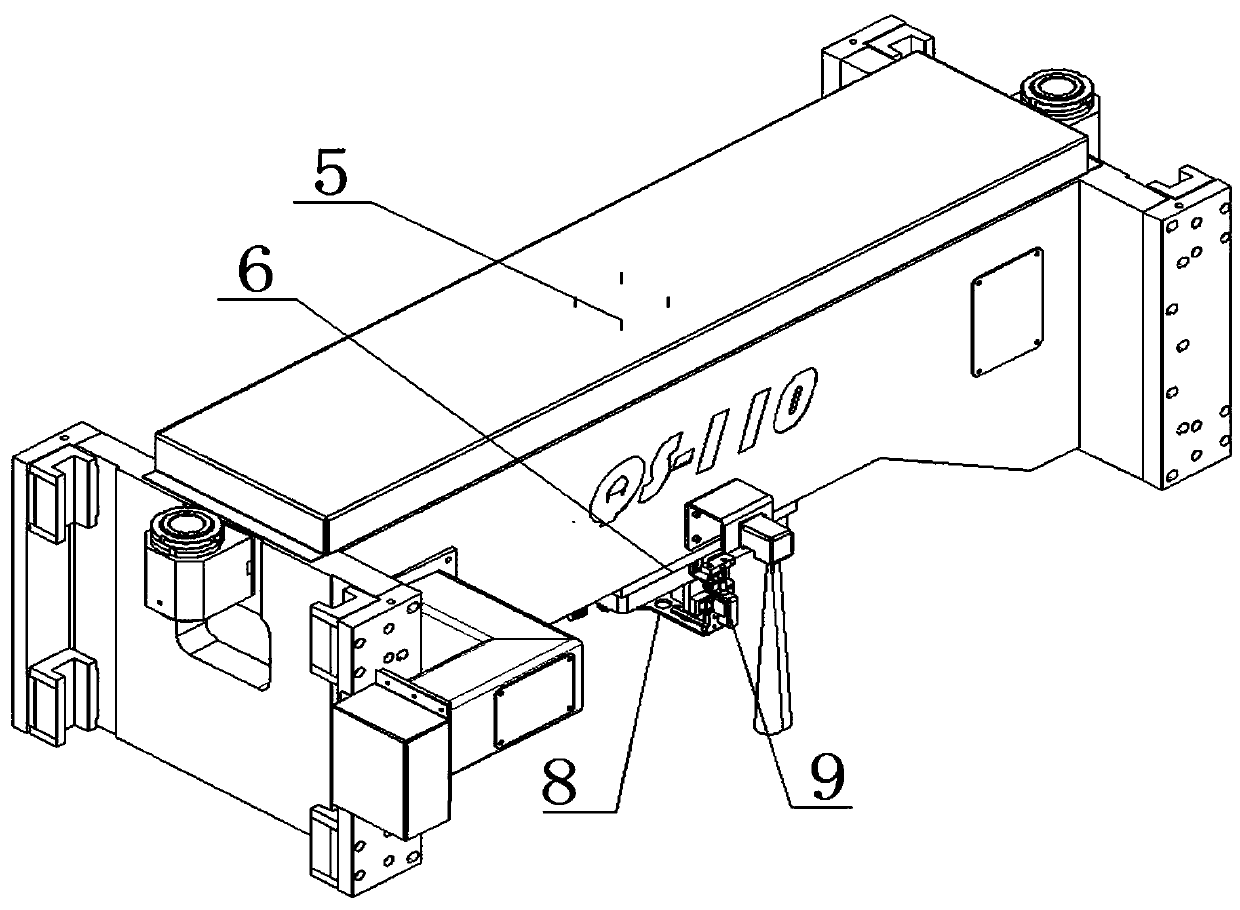

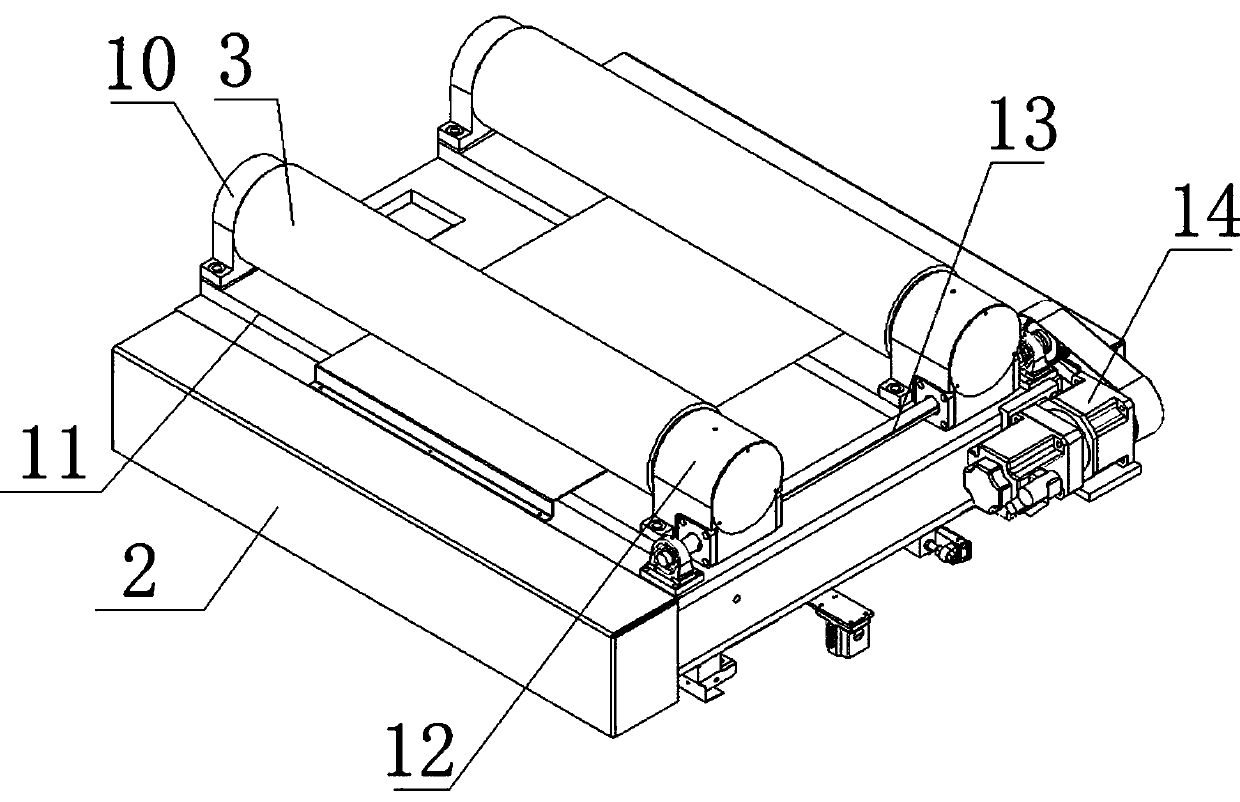

[0022] Such as Figure 1-7 As shown, a large and medium-sized high-voltage motor rotor embedding groove detection mechanism, the high-voltage motor rotor copper bar embedded tight rolling machine bed 1 is provided with a sliding table mechanism 2 capable of horizontal displacement, above the sliding table mechanism 2 is provided The sliding plate 11 driven by the motor can adjust the spacing. The sliding plate 11 is provided with a rotatable driving drum 3, and the two driving drums 3 support the high-voltage motor rotor 7. The ends of the two driving drums 3 are equipped with worm and worm mechanisms. The worm mechanism 12 is connected through a light rod 13, and the light rod 13 is connected with the gear reducer 14, and the gear reducer 14 controls the synchronous operation of the two drive rollers 3 through the light rod 13, so that the high-voltage motor rotor 7 above it realizes indexing operation, and the A gantry 4 is arranged above the sliding table mechanism 2, and i...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap