Wire winding ring jack contact element and wire winding ring jack

A socket contact and wire winding technology, which is applied to the parts, connections, electrical components, etc. of the connection device, to achieve the effects of easy installation, lower temperature rise, and optimized internal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

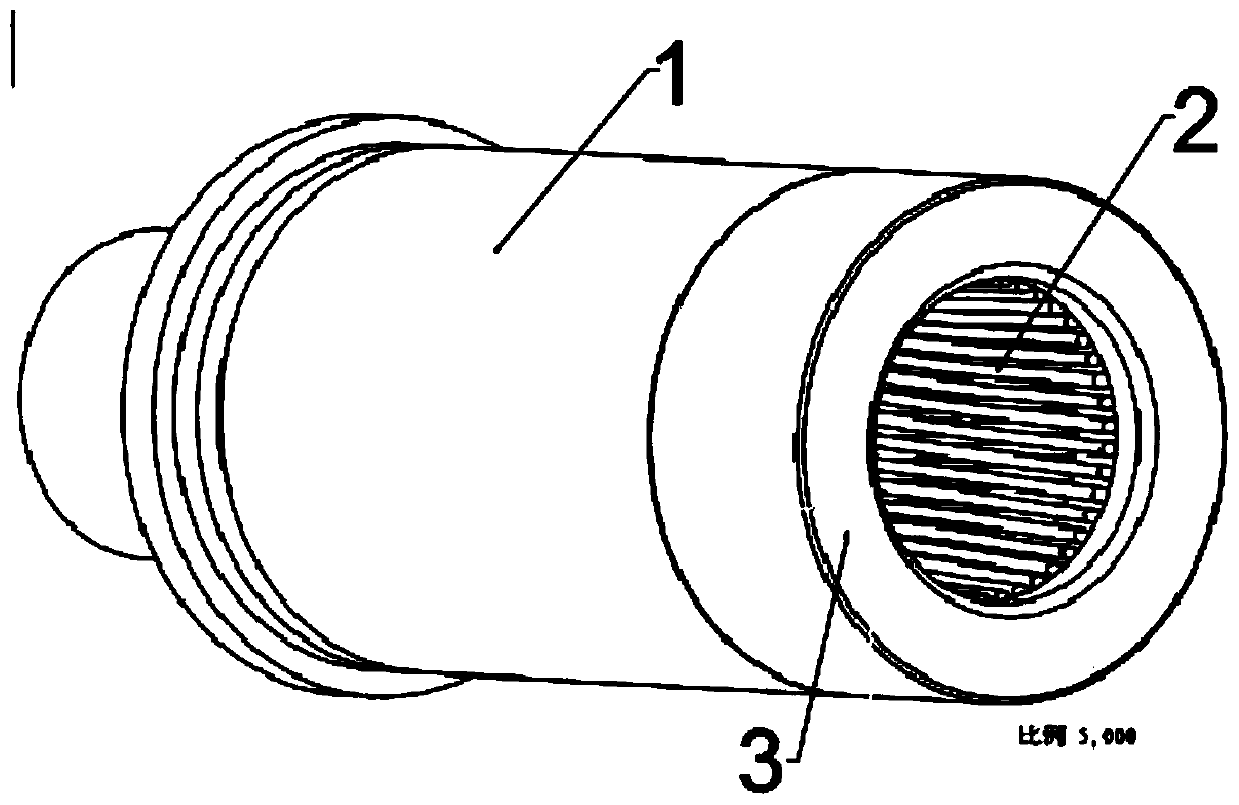

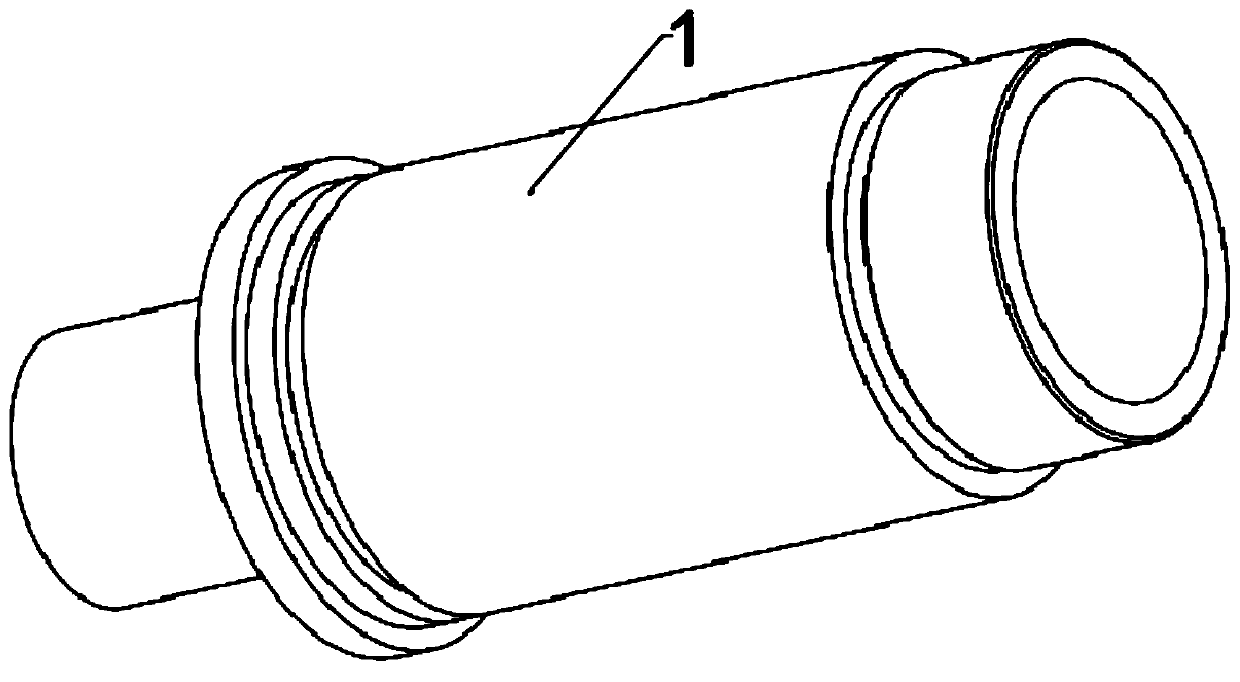

[0015] Example 1, such as Figure 1 to Figure 3 Shown:

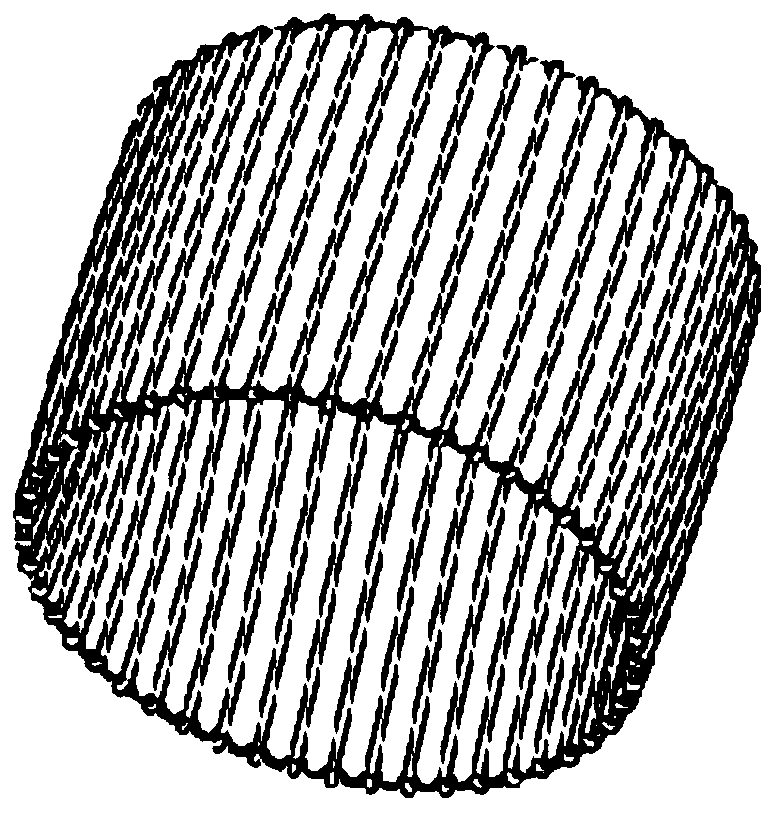

[0016] A wire-wound ring socket contact and a wire-wound ring socket, including a metal copper sleeve 1, a wire-wound spring 2, and a metal gland 3. The wire-wrapped spring 2 is initially in the shape of a strip and rolled into a circle when assembled. Set in 1 hole of metal copper sleeve.

[0017] A preferred technical solution of this embodiment, the coiled wire spring 2 is made of strip-shaped beryllium copper wire or pure copper wire, with a strip-shaped shrapnel as the core, and when viewed from the width direction, the middle strip-shaped shrapnel is the center line. The copper wires are convex in different sizes.

[0018] A preferred technical solution of the present embodiment, it adjusts the spacing p of the wire spring 2 and the diameter of the copper wire Increase its current-carrying size and temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com