A Torque Ripple Suppression Method for Low Speed Direct Drive Permanent Magnet Motor Servo System

A permanent magnet motor and servo system technology, applied in the field of reducing torque ripple and controlling torque ripple, can solve no-load potential, increase manufacturing cost of power output capability, weaken cogging torque amplitude, motor jitter and crawling, etc. problems, to achieve the effect of eliminating inherent shocks, pulsating trends, and good robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the invention will be described in detail below in conjunction with the accompanying drawings.

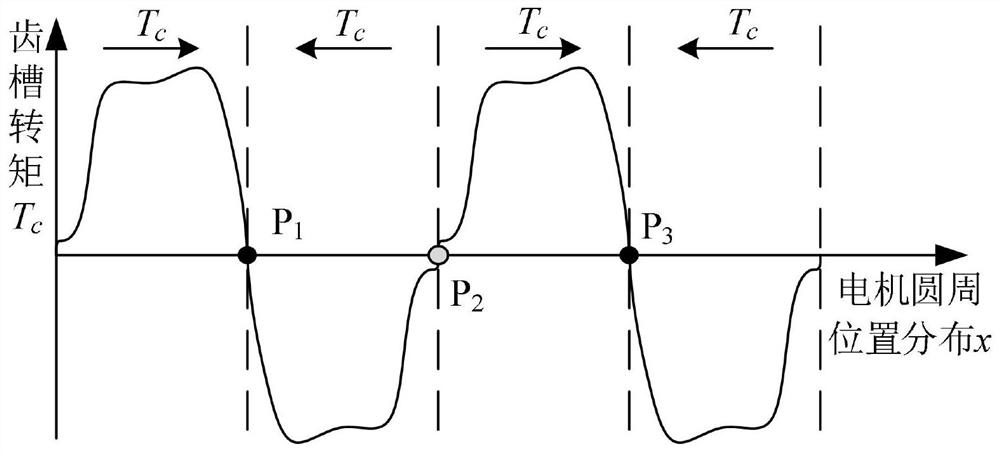

[0027] The cogging torque is uneven in magnitude and distributed in positive and negative directions within one circle of the motor circumference. This positive and negative distributed force enables the motor to be positioned at a certain position. The positioning effect produced by it is as follows: figure 1 As shown, when the cogging torque is positive, the motor rotor deflects positively, and when the cogging torque is negative, the motor rotor deflects negatively. An anchor point is only formed between two deflection forces of equal magnitude and opposite direction. Therefore, P1 and P3 are the positioning points of the motor, while P2 cannot form the positioning point.

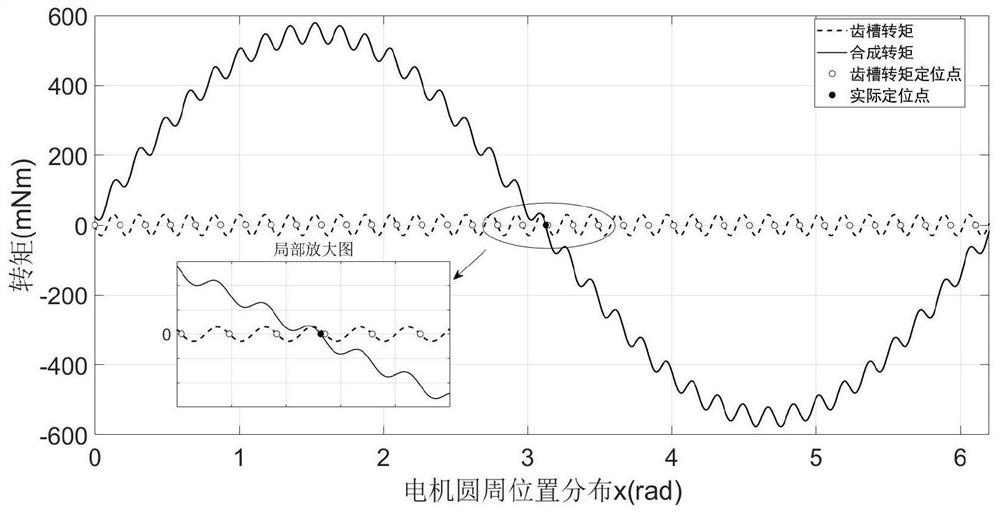

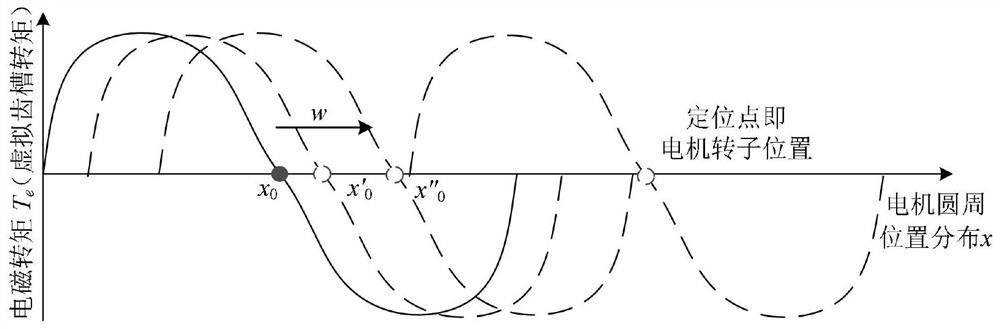

[0028] Based on the above cogging torque positioning principle, the positive and negative electromagnetic torque distributed along the circumference of the motor axis section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com