Horizontally split screw-spindle pump

A screw pump and twin-screw pump technology, applied in the direction of rotary piston pumps, pumps, pump components, etc., can solve problems such as difficult production, achieve simple manufacturing and maintenance, simple assembly, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

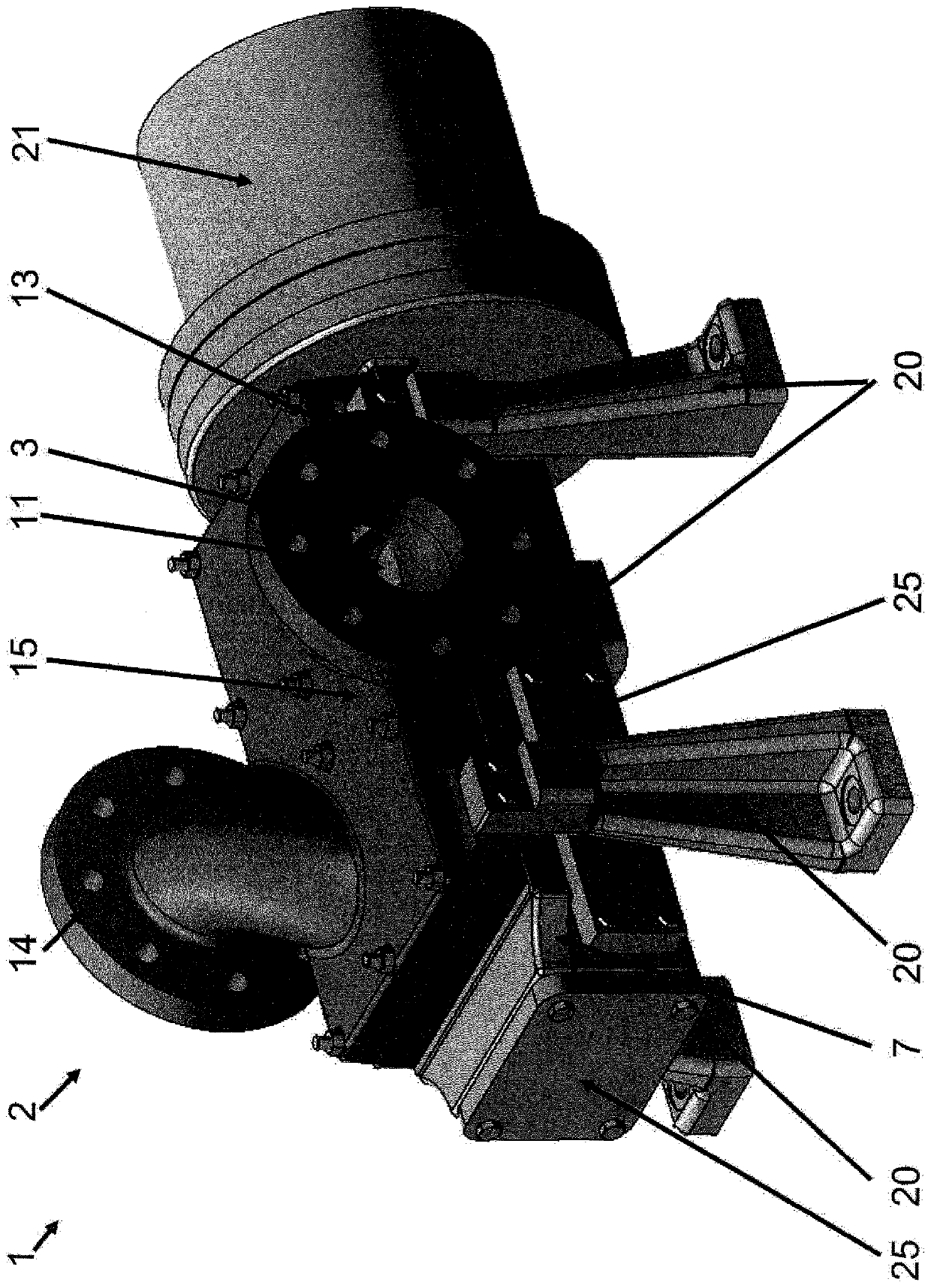

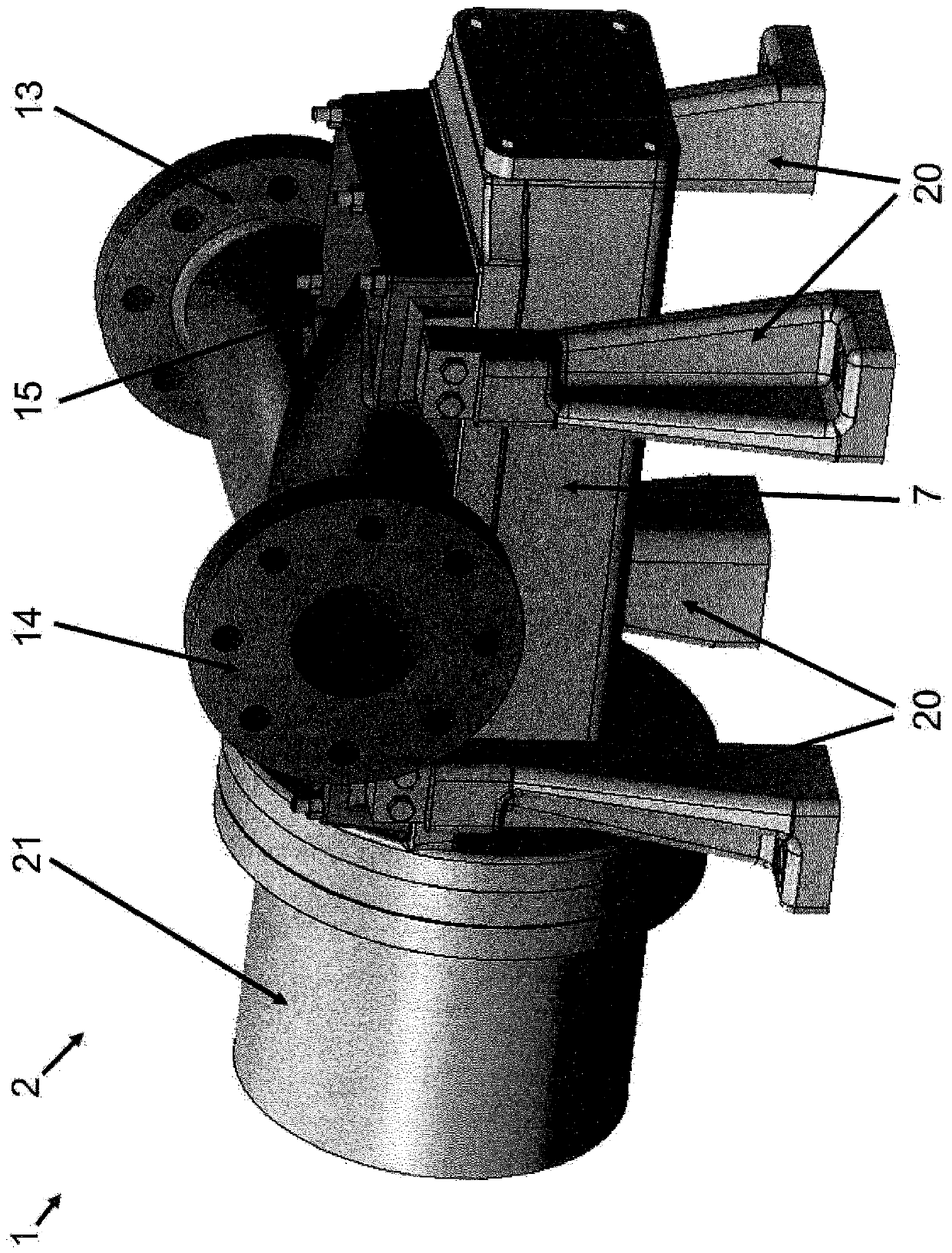

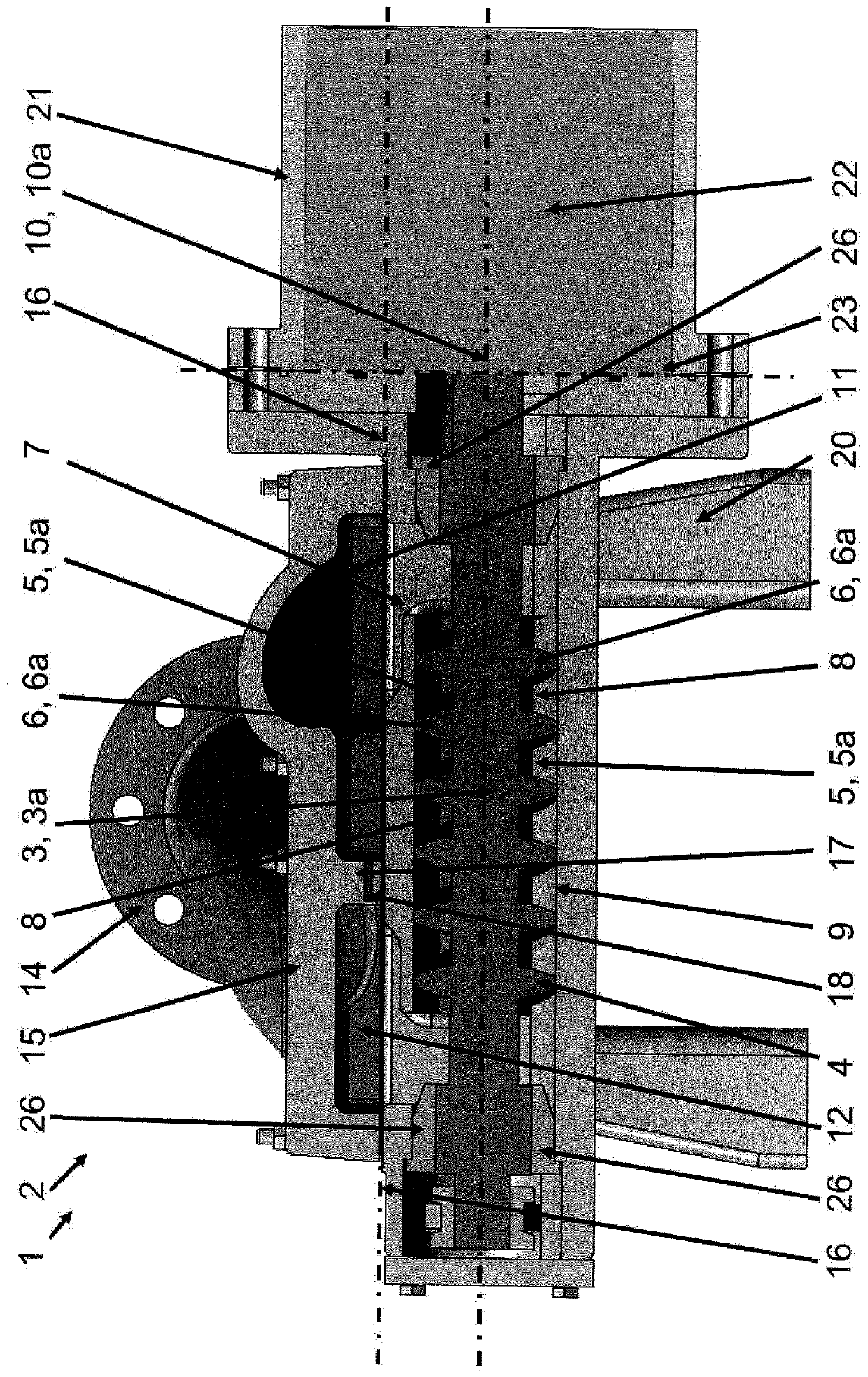

[0033] figure 1 A screw pump 1 is shown schematically, designated by reference numeral 1 . according to figure 1 The drawing shows a progressive cavity pump 1 comprising a multi-part housing 2 . The housing 2 comprises an operating housing part 7 and a connecting housing part 15 as well as a drive housing part 21 .

[0034]In addition to these housing parts 7 , 15 , 21 further housing parts may be provided for connection to said housing parts 7 , 15 , 21 . Thus, a discharge housing may be provided for assembly on the housing parts 7, 15, 21, wherein the discharge housing preferably comprises means to allow the screw pump 1 to be drained for maintenance. Furthermore, an attached housing including a flushing connection can be provided for inspection and cleaning of the progressive cavity pump 1 . It is also possible to use a pressure limiting valve housing and a bypass housing for assembly on the modular housing parts 7 , 15 , 21 of the progressive cavity pump 1 . Furthermo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com