Rice straw pressure burying machine applied to soda saline-alkaline lands

A technology of soda saline-alkali land and rice straw, which is applied in the application, soil lifting machinery, harvester, etc., can solve problems that are not suitable for new agronomic technology requirements, improve ecological governance and restoration effects, reduce power and fuel consumption, and realize Effects of Ikeda's Conditional Requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

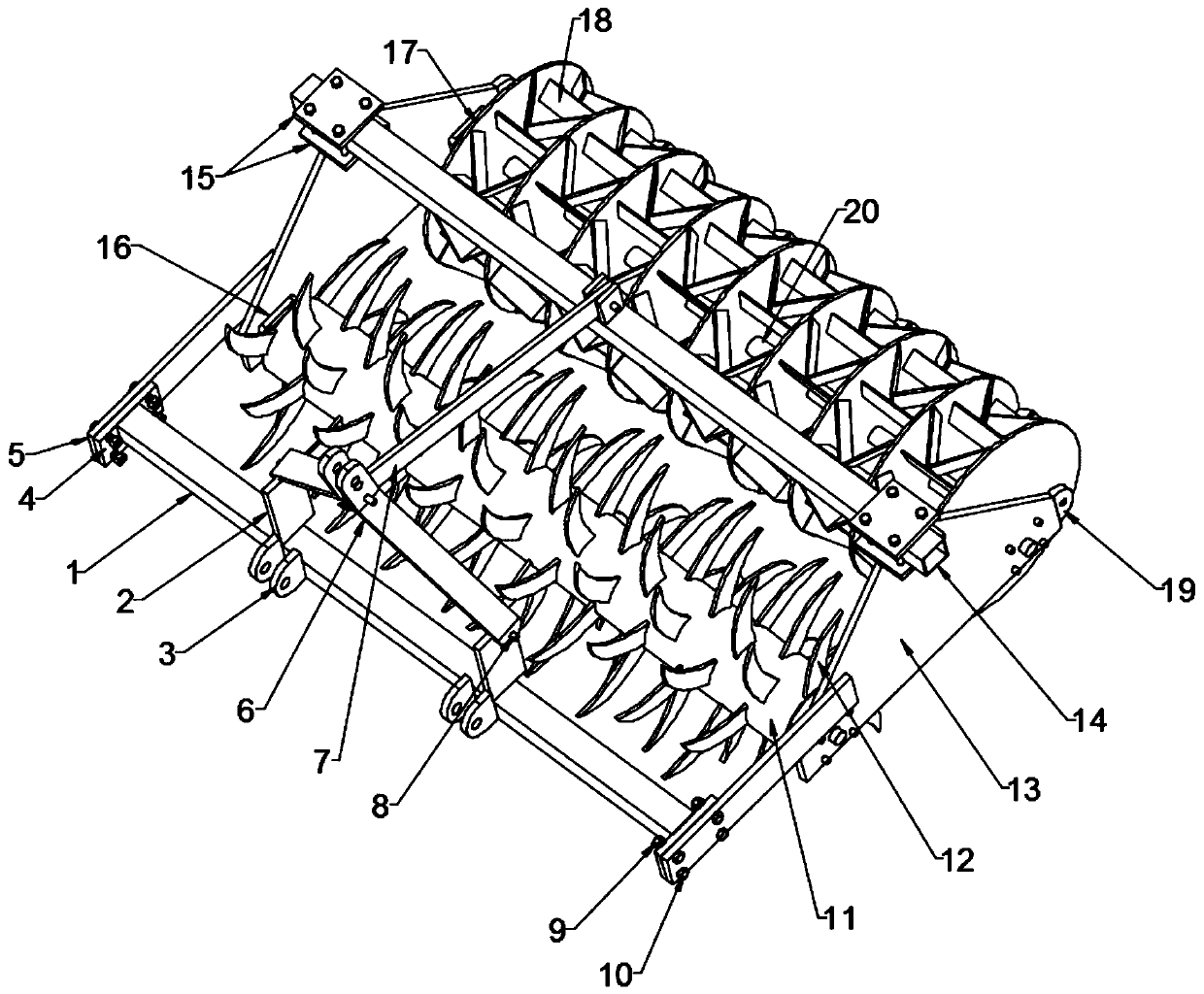

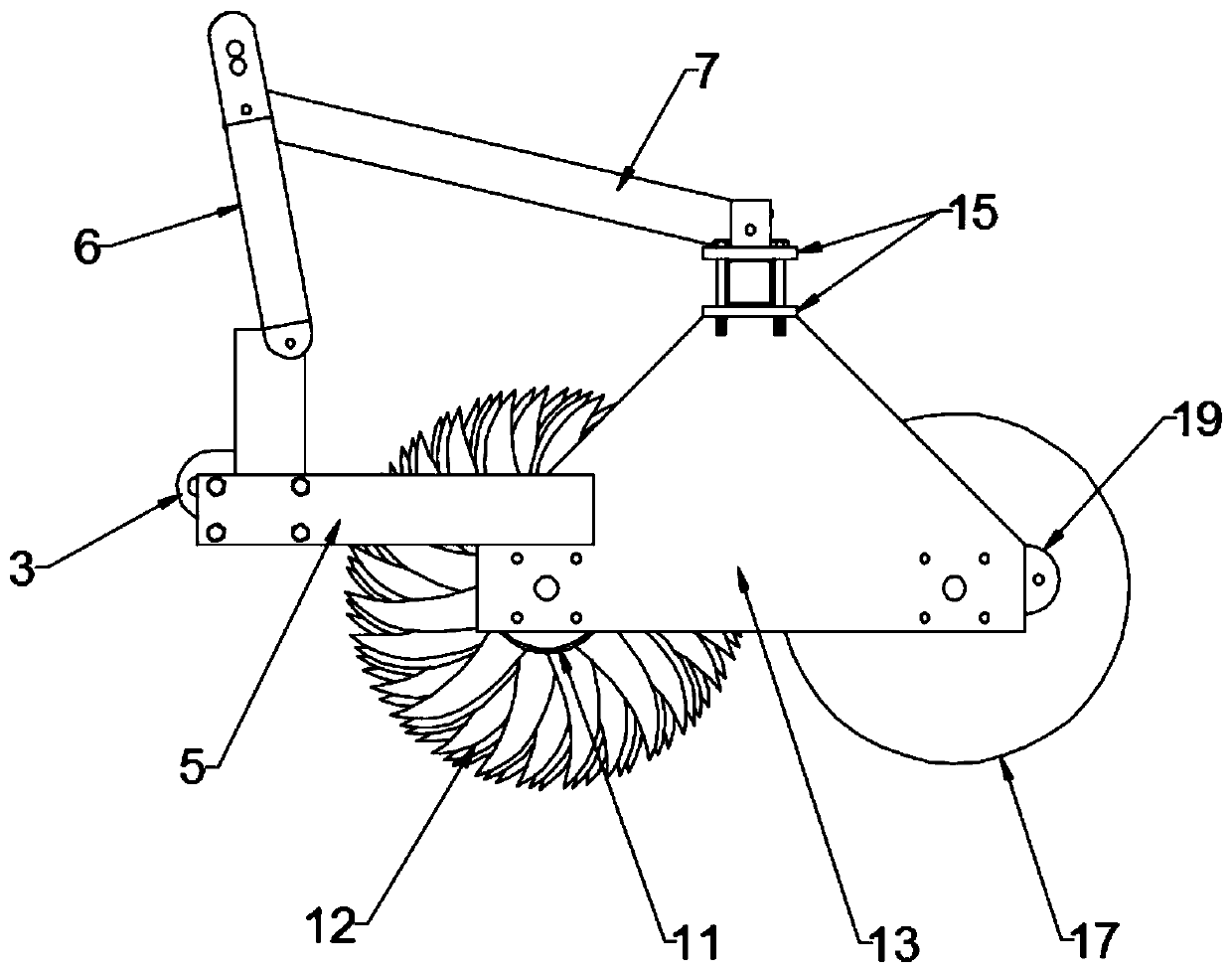

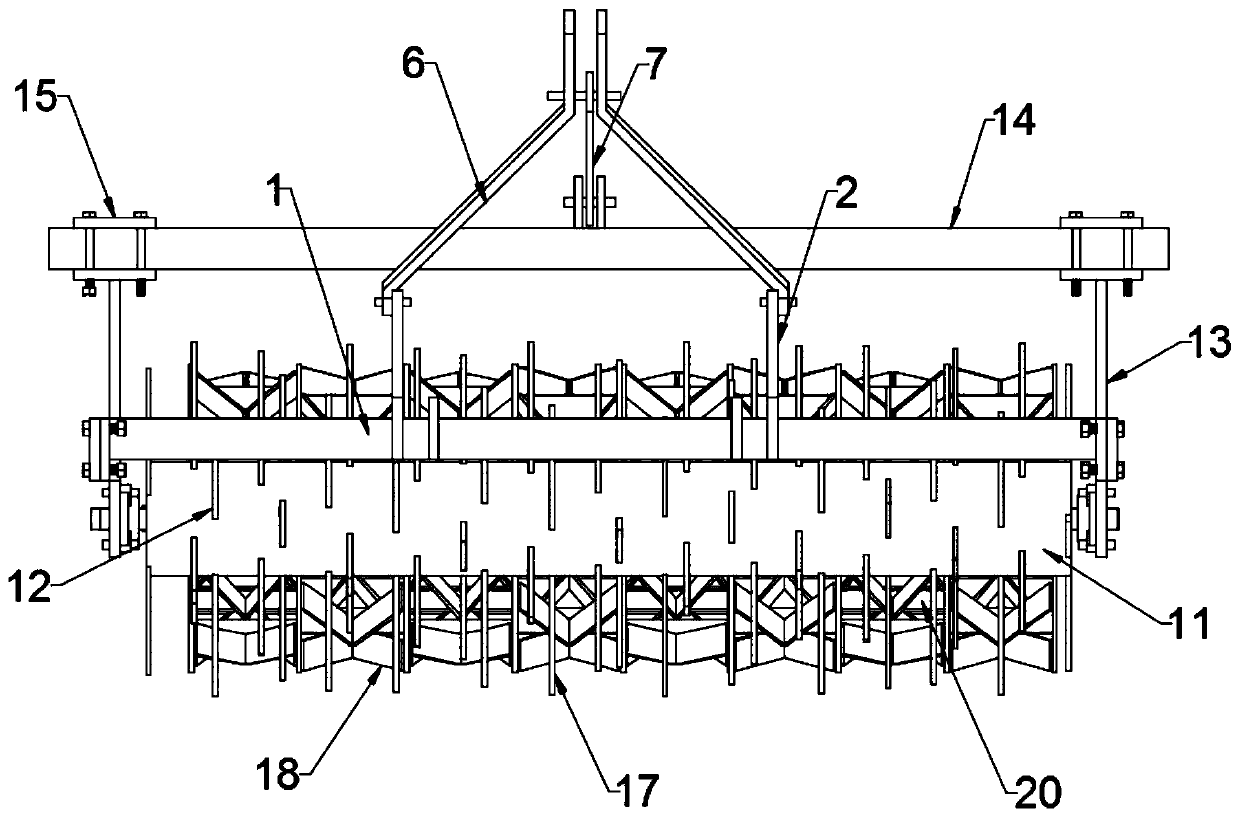

[0044] see Figure 1-5 As shown, a rice straw burying machine applied to soda saline-alkali land is combined with a frame, a star-wheel-type soil stirring roller and a disc-type grass roller to adapt to different paddy field soils and surface straw coverage conditions.

[0045] The frame includes a front beam frame 1, a rear beam frame 14, a pull rod 7 and a roller bracket 13, and the two ends of the front beam frame 1 are welded with a horizontal welding plate 4, and the horizontal welding plate 4 is connected to the frame plate through a bolt 10 and a nut 9 5. The frame plate 5 is welded on the front side of the roller bracket 13, the top of the roller bracket 13 is welded with a pressure plate 15, and the rear beam frame 14 is installed above the pressure plate 15, and the rear beam frame 14 is arranged between the two roller brackets 13, and the end of the rear beam frame 14 The upper and lower sides of the back beam frame 14 are fixed by the pressing plate 15, and the pre...

Embodiment 2

[0052] see Figure 10 , Figure 11 As shown, a rice straw burial machine applied to soda saline-alkali land is combined by using a frame and two sets of disc-type grass rollers installed on the frame. The frame and the structure disclosed in Embodiment 1 are the same, and the To adapt to different paddy field soil and surface straw cover conditions.

[0053] The round-hole type stubble-returning roll includes a return-sizing and grass-returning roller 25, a return-sizing hole 26, a side plate 27 and a return-sizing and pressing grass roller shaft 28, and the surface of the returning-sizing and pressing grass roller 25 is evenly provided with several Returning slurry hole 26, returning slurry and pressing grass roller 25 two ends are welded with side plate 27, and side plate 27 is fixed on returning slurry pressing grass roller shaft 28, has beating, the effect of flat ground.

Embodiment 3

[0055] see Figure 12-14 As shown, a rice straw burial machine applied to soda saline-alkali land includes a frame, a star-wheel soil stirring roller, a disc-type grass pressing roller and a round-hole stubble-returning roller for combination. The frame, star wheel The structure of the soil stirring roller, the disc-type grass-pressing roller and the round-hole-type stubble-pressing and slurry-returning roller are the same as those disclosed in Embodiment 1, and are used to adapt to different paddy field soils and surface straw mulching conditions.

[0056] In an embodiment of the present invention, the disc pressing grass roller shaft 20, the soil stirring roller shaft 21 and the returning pulp and grass pressing roller shaft 28 can all be installed in the bearing housing 16 between the roller brackets 13, and the ball bearings 23 Driven by the transmission and the frame to rotate.

[0057] see Figure 1-4 as well as Figure 10 , Figure 12-14 As shown, the results of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com