Special end executor for assembly robot for large thread cap of steel barrel

A technology of end effector and screw cap, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problem of low assembly efficiency of large screw cap of steel drum, and achieve the effect of compact structure, high efficiency and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

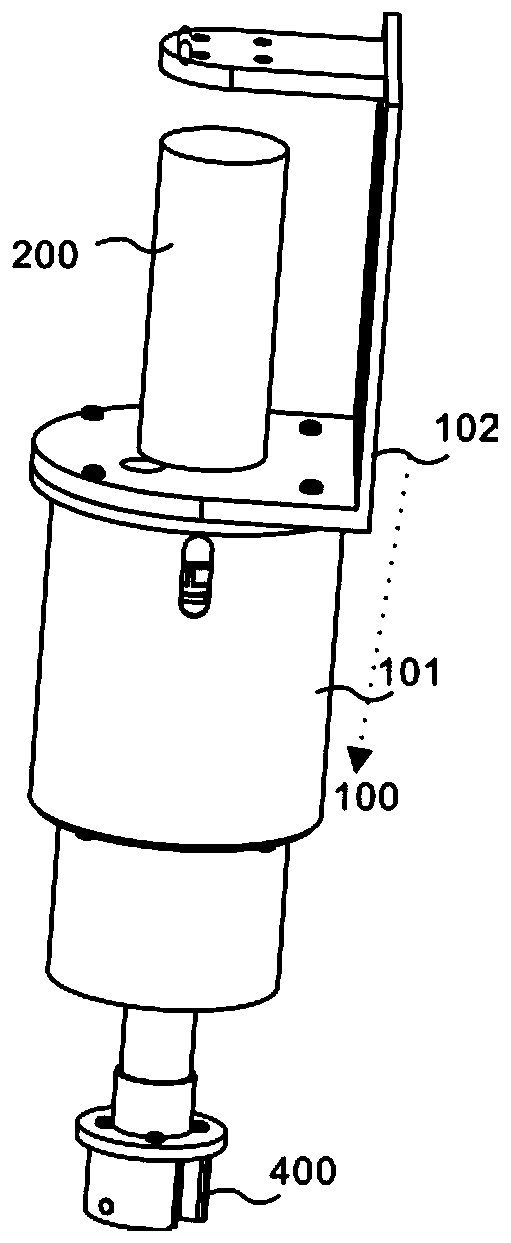

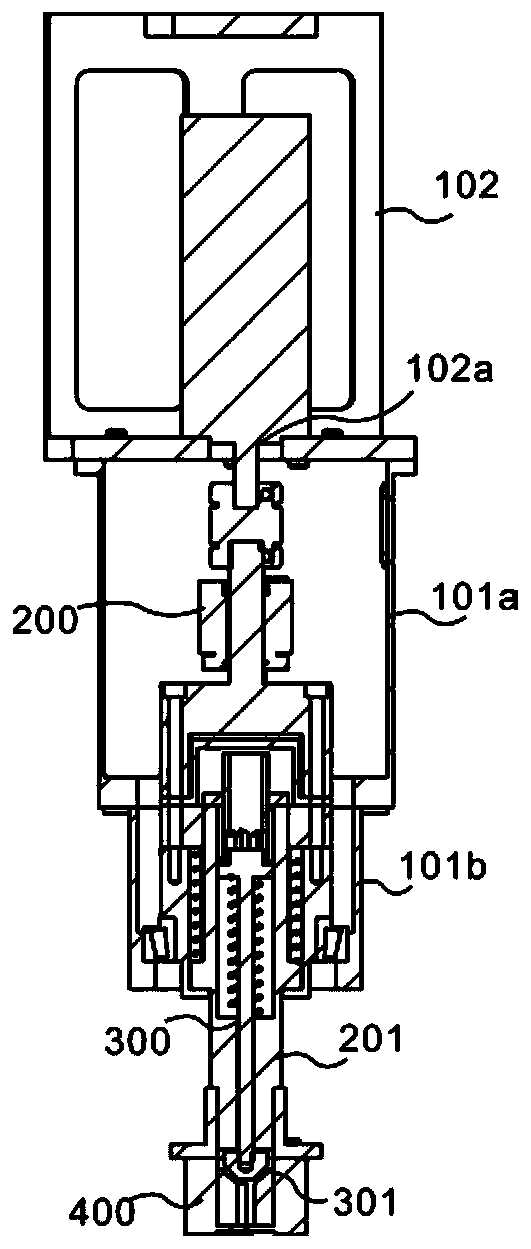

[0048] refer to Figure 1 ~ Figure 3 , provides a schematic diagram of the overall structure of a special end effector for a large screw cap assembly robot for steel drums, as shown in figure 1 , a special end effector for a steel drum large screw cap assembly robot includes a protective assembly 100, including a sleeve part 101 and a mounting frame 102, and the mounting frame 102 is arranged on the sleeve part 101; a driving assembly 200 is embedded in the sleeve part 101 ; the push rod assembly 300 , which cooperates with the pusher 201 of the drive assembly 200 ;

[0049] Specifically, the main structure of the present invention includes a protection assembly 100, a drive assembly 200, a push rod assembly 300, and a clamping assembly 400. The cooperation improves the stability of the grasping, positioning and tightening of the large threaded cap of the steel drum, thereby greatly improving the assembly efficiency of the large threaded cap of the steel drum. Among them, the...

Embodiment 2

[0053] refer to Figure 4 , This embodiment is different from the first embodiment in that: the driving assembly 200 also includes a drive motor 202, an anti-winding measuring part 203 and a transmission part 204, through the setting of the pushing part 201, the driving motor 202, the anti-winding measuring part 203 and The mutual cooperation between the transmission parts 204 provides a power source for tightening the screw cap, and provides a transmission force for the clamping assembly 400, and at the same time, it can solve the winding problem of the static torque sensor rotating with the motor. Specifically, the drive assembly 200 also includes a drive motor 202, an anti-winding measuring piece 203 and a transmission piece 204. The driving motor 202 is the power source for screwing the screw cap to the steel threaded port, and the anti-winding measuring piece 203 is used to solve the problem of static torque. The winding problem of the sensor with the rotation of the moto...

Embodiment 3

[0061] refer to Figure 8 , This embodiment is different from the above embodiments in that: the clamping assembly 400 also includes a first contracting part 402 and a second contracting part 403, and the clamping shell 401, the first contracting part 402 and the second contracting part 403 are provided The mutual cooperation between them can ensure the stability of the large threaded cover of the clamping steel drum and the effect of installation. Specifically, the clamping assembly 400 also includes a first shrinking part 402 and a second shrinking part 403, the first shrinking part 402 and the second shrinking part 403 are used for clamping the large screw cap of the steel drum and can be contracted according to the needs of use. The first constriction part 402 and the second constriction part 403 are disposed symmetrically in the third groove 401 a of the clamping shell 401 . It should be emphasized that the first constriction part 402 and the second constriction part 403 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com