Presser structure for knitting bamboo summer sleeping mat

A technology of presser feet and mats, applied in mechanical equipment, sugarcane machining, etc., can solve the problems of easy recovery of bending of bamboo strips and limited flattening effect, and achieve the effects of low cost, good quality of finished products, and high weaving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

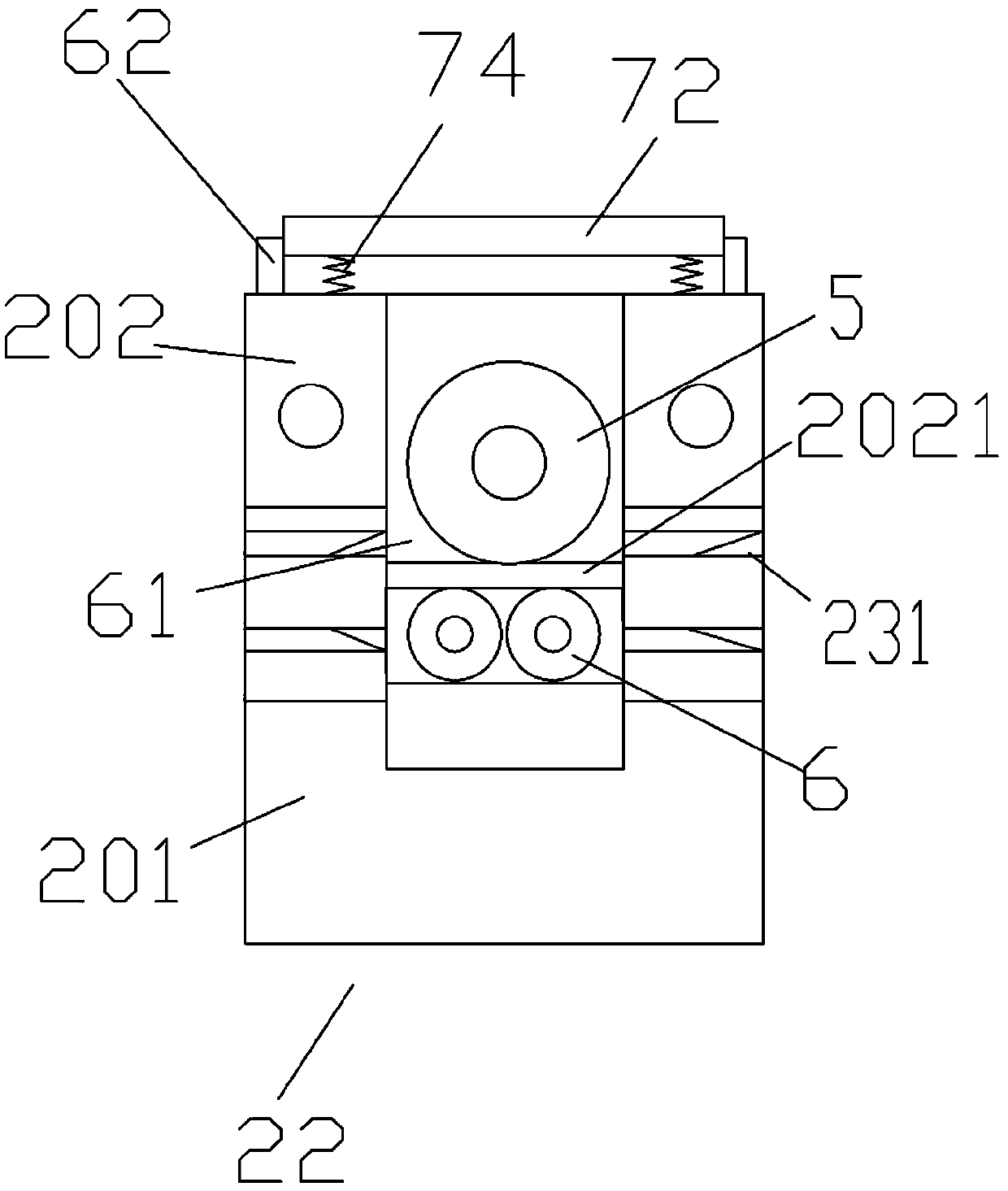

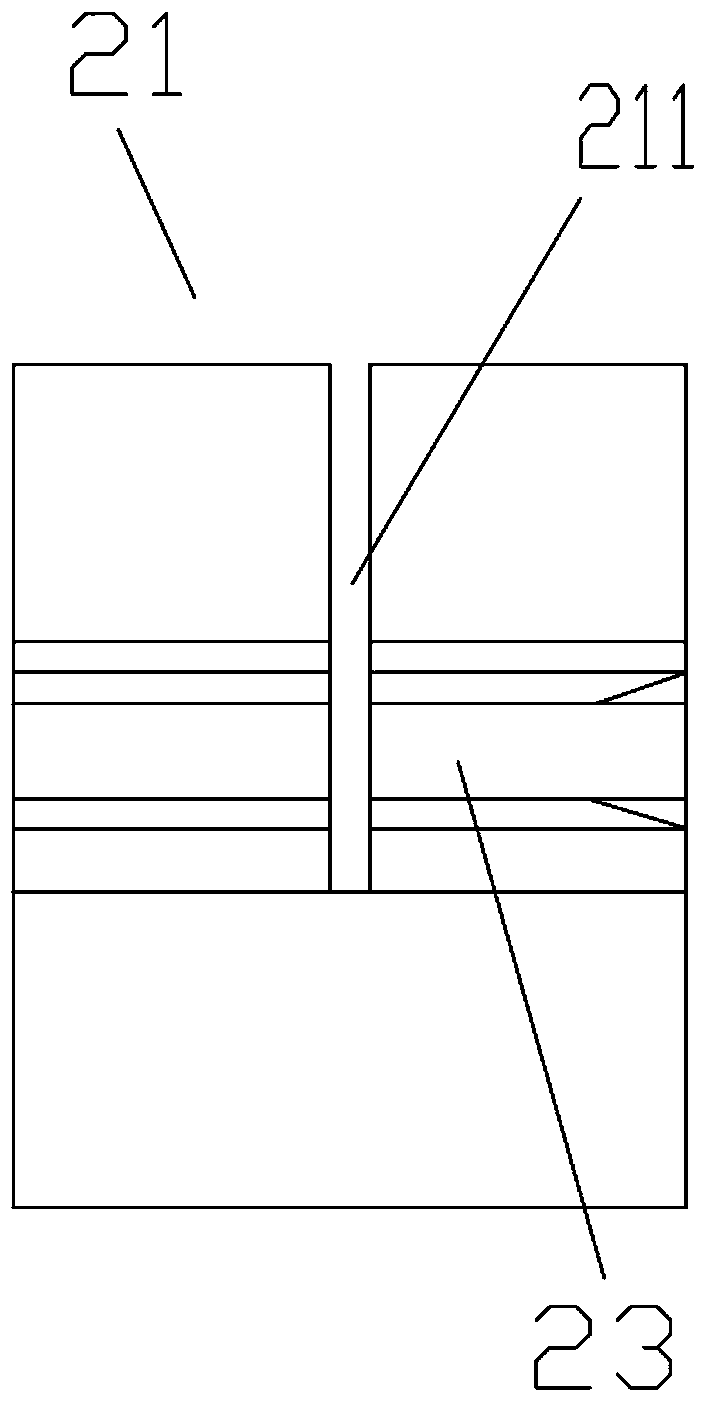

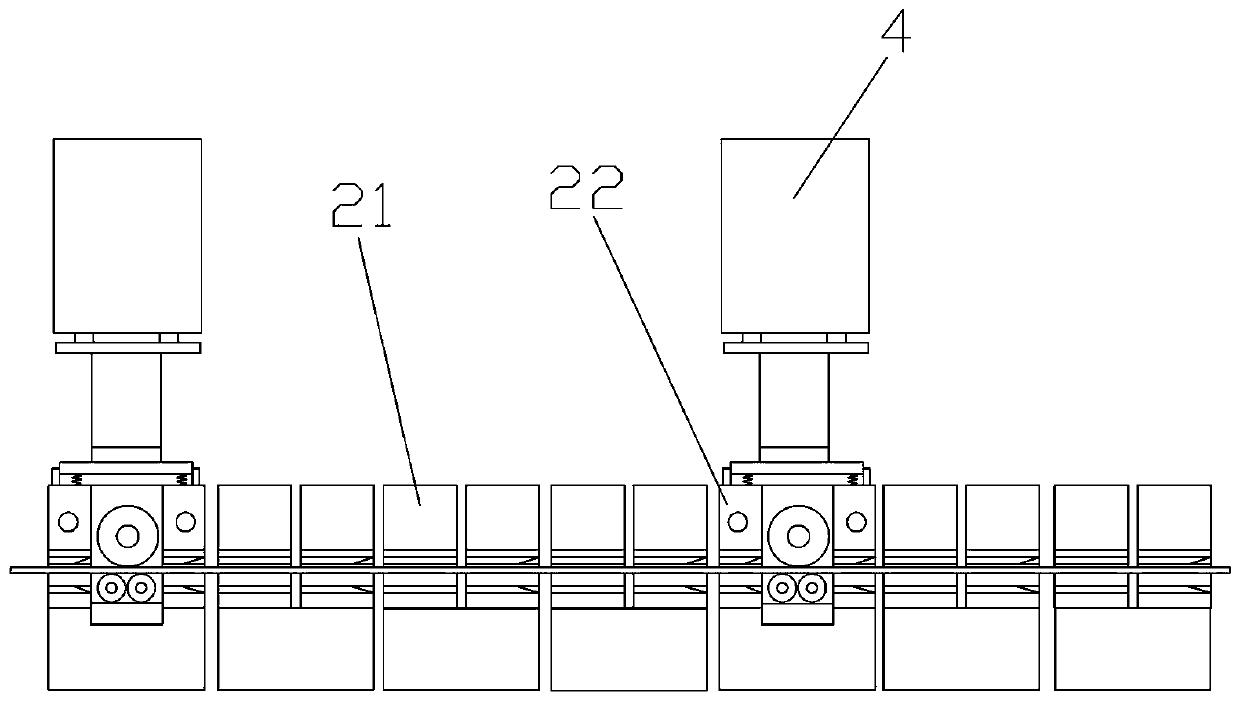

[0034]A presser foot structure for weaving bamboo mats, the presser foot includes a channel presser foot 21 that can be arranged alternately and communicates with each other, a correcting presser foot 22 with adjustable channels, and a presser foot that cooperates with the correcting presser foot The braking element 4 used to control the channel size of the correcting presser foot; at least the correcting presser foot is provided with a bearing with the outer ring peripheral surface as a part of the channel wall in the channel presser foot and the correcting presser foot, and the channel presser Both the foot and the correcting presser foot include a lower mounting plate positioned at the bottom and an upper mounting plate 202 that is connected to the top of the lower mounting plate and has a channel slot 23 that is used to form a channel with a notch forward and through at both ends; A bearing installation cavity 2021 is provided in the middle section of the passage groove, an...

Embodiment 2

[0040] The difference from the above embodiments is that the bearing mounting cavity is a through cavity that runs through the upper mounting plate or the upper mounting plate and part of the lower mounting plate and has an open top. The bearing installation back plate 61 on the back of the plate and between the upper mounting plate and the guide groove plate, the guide rail groove is arranged between the guide groove plate and the bearing installation back plate.

[0041] Described guide rail bar rack comprises two guide rail bars 71 that are arranged in parallel and is located in the described guide rail groove, is respectively connected to the upper frame bar 72 and the lower frame bar 73 between two guide rail bar tops and the bottom, and described lower adjustment The bearing is installed on the lower frame bar, and the upper frame bar is the load-bearing reset part located above the top of the upper mounting plate. The front side of the upper frame bar extends forward be...

Embodiment 3

[0045] The difference from the above embodiment is that the upper positioning bearing includes one or more large bearings arranged coaxially, the lower adjusting bearings are divided into two groups arranged in parallel, and each group includes one or more large bearings arranged coaxially. The small bearing that shaft is arranged; The one end notch that welcomes in the end notch of bamboo strip 10 in the end notch of at least two ends of described channel groove is horn notch 231. The cooperation of the triangular positions of the large and small bearings is conducive to the stable flattening of the bamboo strips, and the notch of the horn is convenient for the sliding of the bamboo strips.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com