Inverted precision plastic mold and assembling method of mold oil cylinder

A precision plastic and mold technology, applied in the field of molds, can solve the problems of violent movements, loosening of the oil cylinder 5, film release, and difficulty in the process of taking out the injection molded products, and achieves the effect of compact structure design, firm structure, and tight connection relationship.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

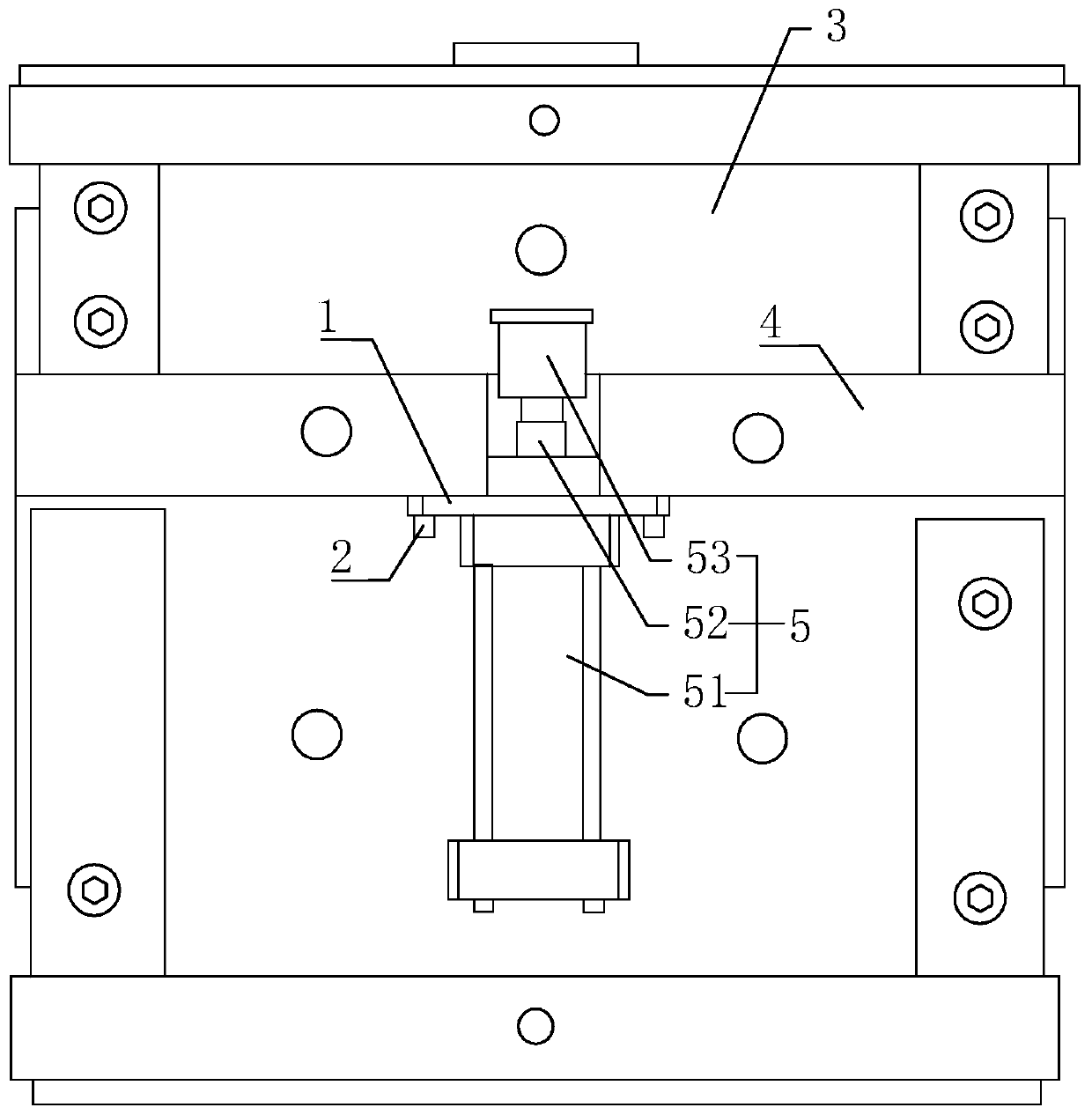

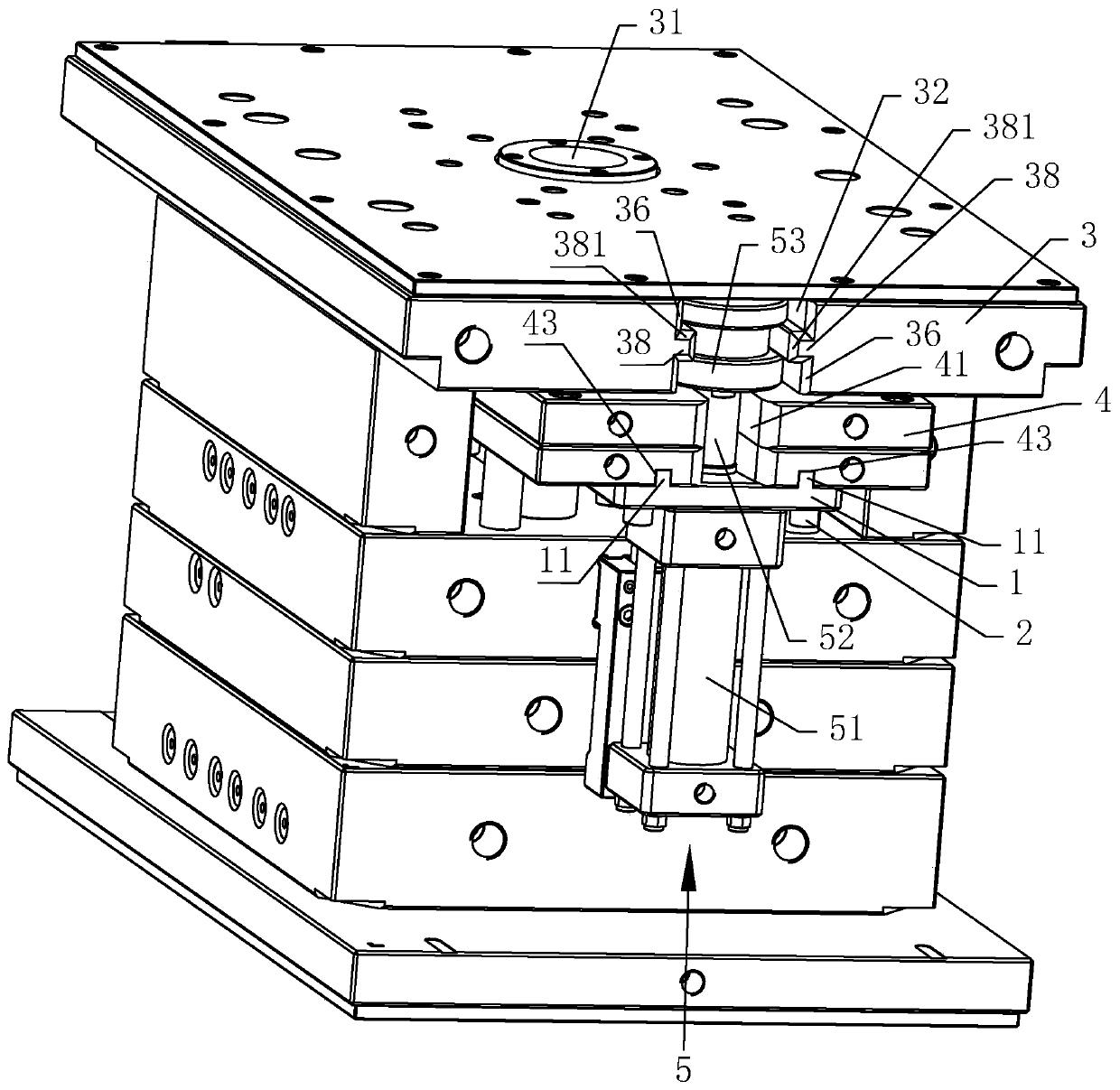

[0046] refer to figure 2 and image 3 , is an inverted precision plastic mold disclosed by the present invention, comprising: a front template 3, a push plate 4 and an oil cylinder 5, the front template 3 is provided with a glue inlet 31, and the oil cylinder 5 includes: a cylinder body 51, a telescopic rod 52 and a clamp Connecting block 53, clamping block 53 is fixed on the end of telescopic rod 52 away from cylinder body 51, and a fixed plate 1 is fixed on cylinder body 51, and telescopic rod 52 stretches out fixed plate 1, and fixed plate 1 is fixed by multiple sets of fixing screws 2. The cylinder body 51 is fixed on the push plate 4 .

[0047] The side end surface of the push plate 4 is provided with a first gap 41 for the telescopic rod 52 to pass through, and the side end surface of the front template 3 is provided with a second gap 32 for accommodating the snap-in block 53, and the middle position on both sides of the snap-in block 53 is set There is a card slot 531...

Embodiment 2

[0062] refer to figure 2 and Image 6 , is an assembly method of a mold cylinder disclosed in the present invention, based on the inverted precision plastic mold described in Embodiment 1, the assembly method includes:

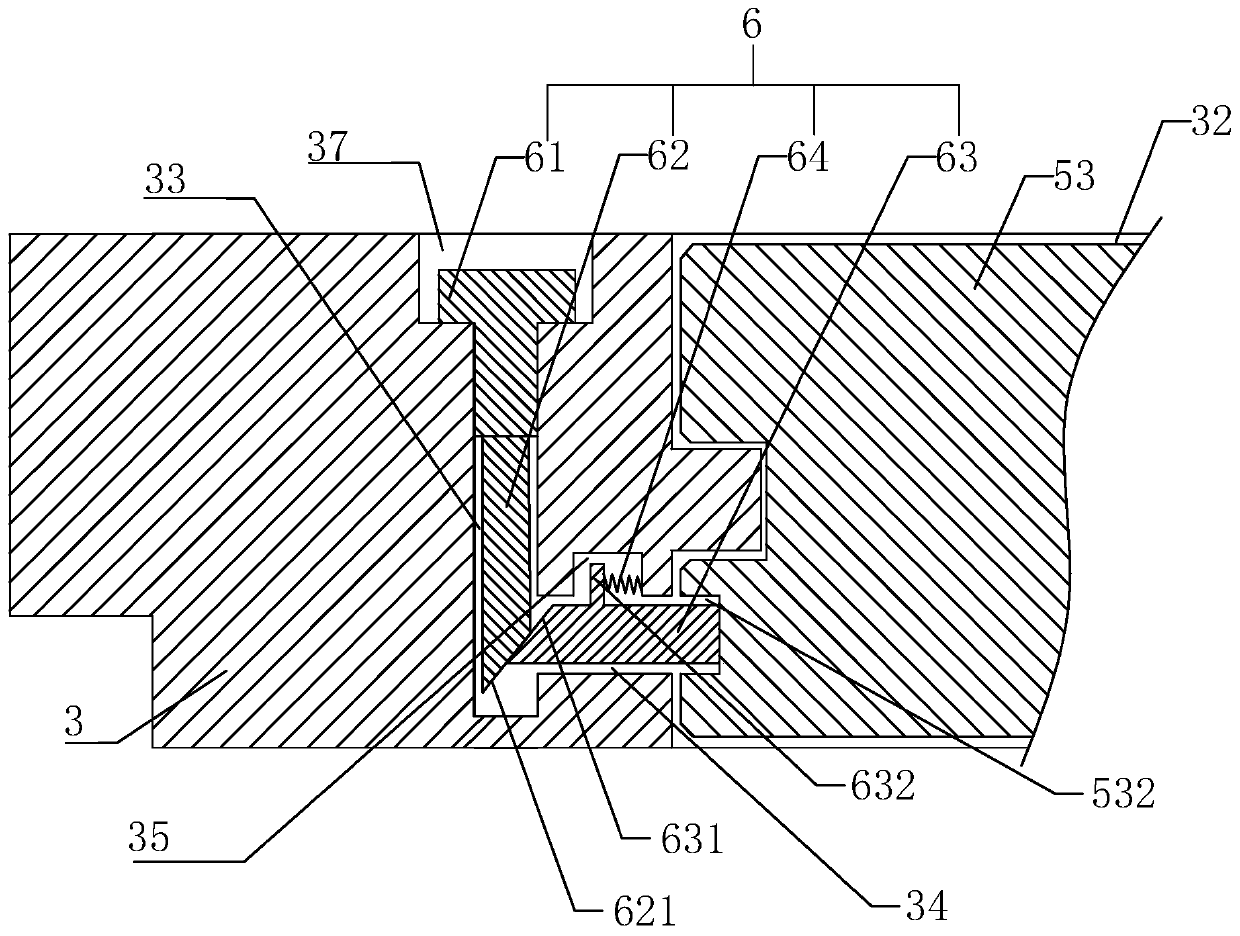

[0063] S1: pass the telescopic rod 52 through the fixed plate 1, so that the fixed plate 1 and the cylinder body 51 are fixedly connected, and the clamping block 53 is fixedly connected with the telescopic rod 52; S2: clamp the clamping block 53 into the second gap 32, Insert the telescopic rod 52 into the first notch 41, and then fix the fixed plate 1 and the push plate 4 through the fixing screw 2; S3: Use a tool (the tool can be a screwdriver or a hexagonal wrench, etc.) to screw the bolt 61 and push it vertically The rod 62 moves down in the vertical cavity 33, and the vertical push rod 62 pushes the horizontal latch 63 to move horizontally in the horizontal cavity 34, and at the same time, the slide block 631 compresses the reset spring 64 in the chute ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com