Double-row roller conveying line with steering mechanism

A technology of steering mechanism and conveying line, which is applied in the direction of conveyor objects, transportation and packaging, roller tables, etc. It can solve the problems of high labor intensity, easy rotation deviation, and influence on detection alignment, etc., so as to save labor costs and improve operation efficiency. Fast, fast-executing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

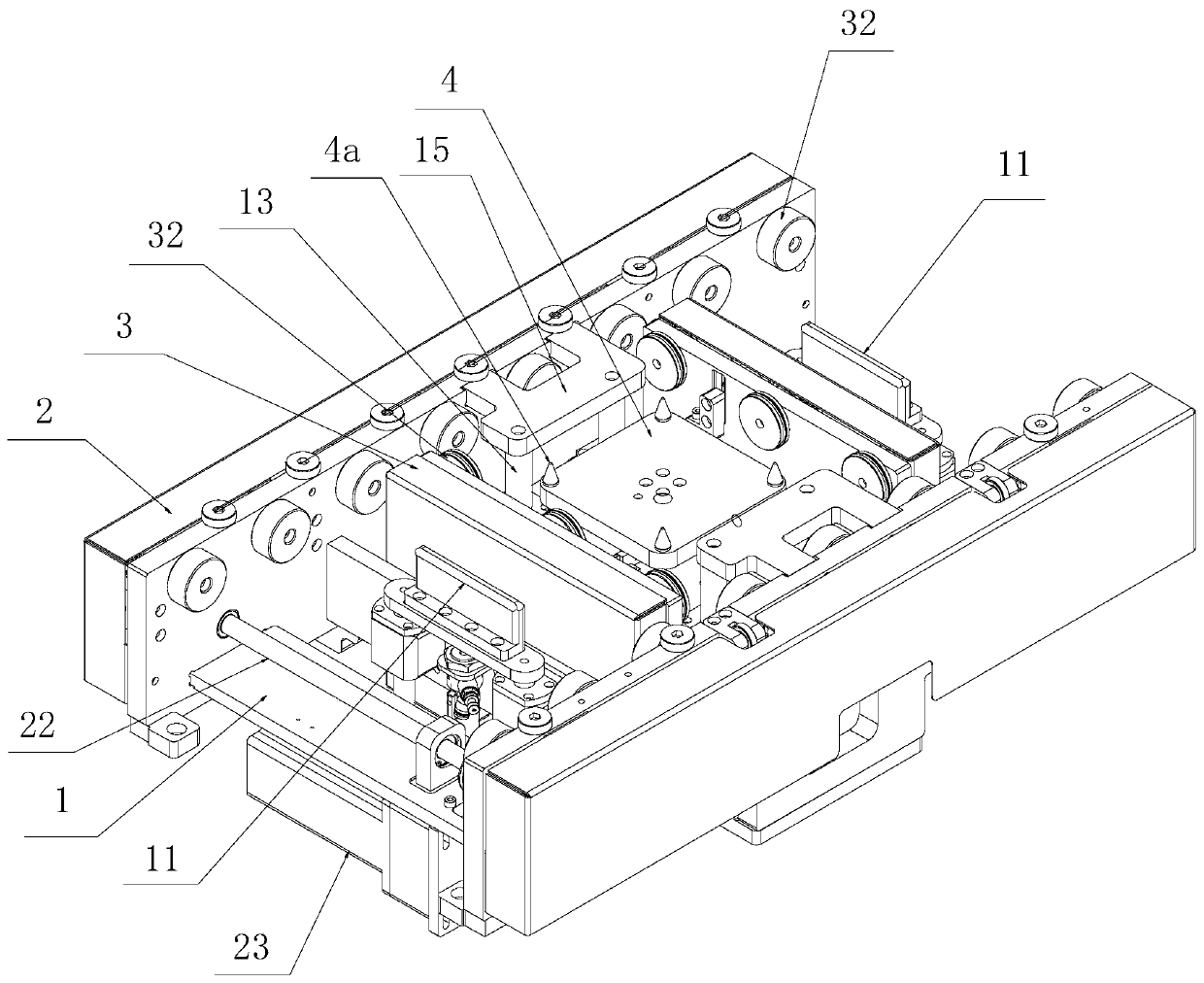

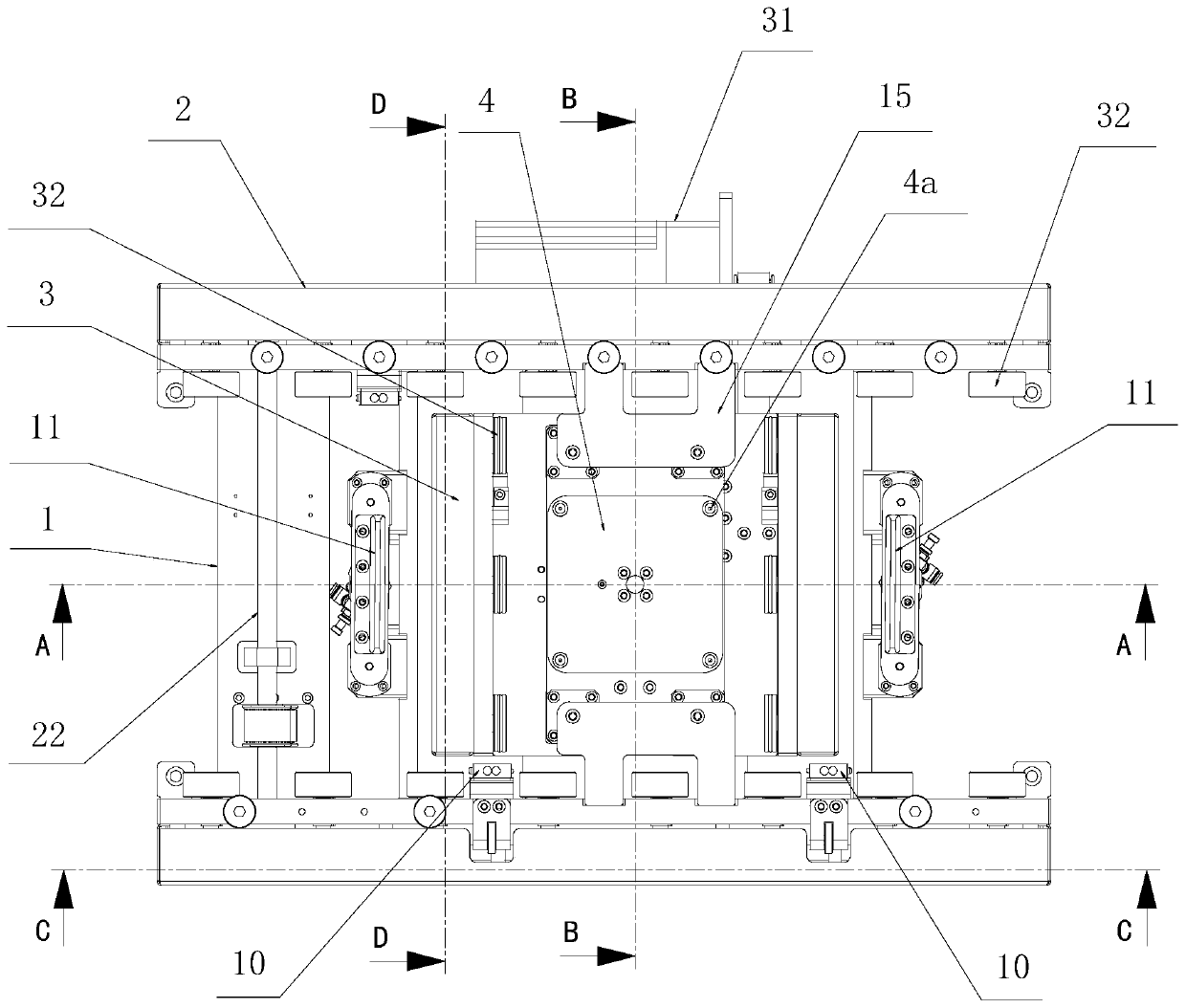

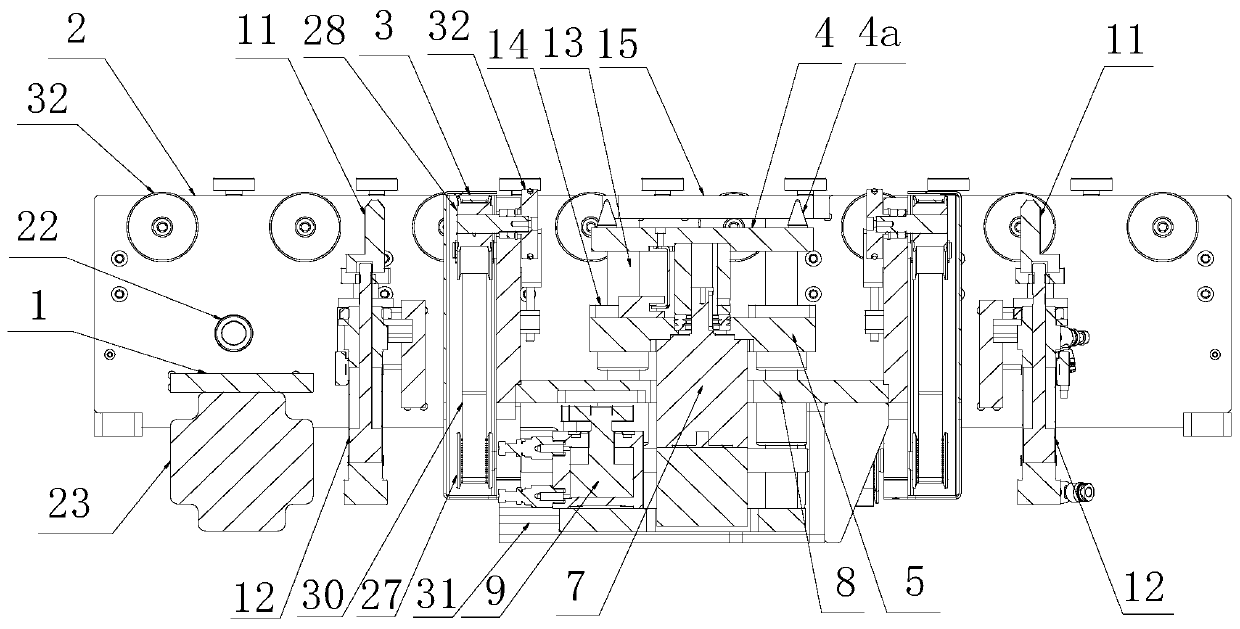

[0034] Example: Combine Figure 1~Figure 6 As shown, the specific implementation of the double-row roller conveyor line with steering mechanism provided by the present invention is described in detail as follows:

[0035] like figure 1 and figure 2 As shown, the present invention has a frame 1 and a first double-row roller conveyor line 2 and a second double-row roller conveyor line 3 arranged on the frame 1 for conveying product plywood, wherein the second double-row roller conveyor line 3 It is located inside the first double-row roller conveyor line 2 and arranged perpendicular to it, and the core improvement feature of the present invention is that a steering mechanism is provided at the intersection center of the first double-row roller conveyor line 2 and the second double-row roller conveyor line 3 .

[0036] further combined image 3 and Figure 4 As shown, the steering mechanism in the present invention is fixed on the jacking platform 5 by the rotating position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com