A method for treating inorganic wastewater containing ammonia nitrogen and sulfate based on sulfur cycle

A sulfate and ammonia nitrogen technology, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of excessive oxidation of elemental sulfur and difficult oxidation of sulfide, and reduce dependence , the effect of reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

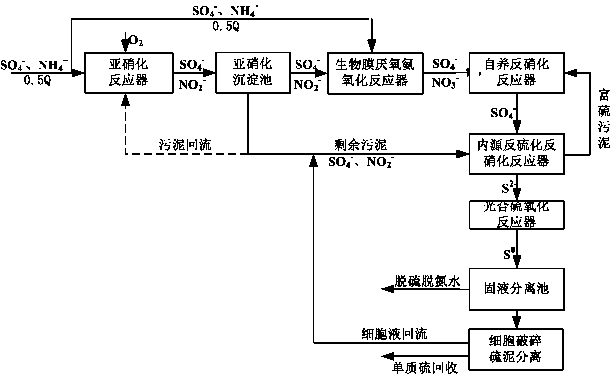

[0022] A treatment method based on sulfur cycle to realize ammonia nitrogen and sulfate inorganic wastewater, including nitrification pond, nitrification sedimentation pond, anammox biofilm pond, sulfur autotrophic denitrification pond, desulfurization pond, photosynthetic sulfur oxidation pond , a solid-liquid separation tank, an ultrasonic crushing system and a reflux system, comprising the following steps:

[0023] S1. Using part of the nitrification tank, anammox biochemical membrane tank and sulfur autotrophic denitrification tank to form an autotrophic denitrification process to remove nitrogen from wastewater;

[0024] S2. Using the anti-sulfurization pool, photosynthetic sulfur oxidation pool and ultrasonic crushing system to realize the conversion and recovery of sulfate to elemental sulfur;

[0025] S3. Use the remaining sludge in the sewage treatment process as the organic carbon source for anti-sulfurization, and use photosynthetic sulfur bacteria to finally store ...

Embodiment 2

[0029] On the basis of Example 1, in this embodiment, a sub-digestion reactor is set in the nitrosation tank, and the sub-digestion reactor reacts all the ammonia nitrogen in 50% of the waste water in combination with oxygen, converts it into nitrite, and The mud-water separation is realized in the sedimentation tank, and the water enters the anammox biofilm tank; the remaining 50% of the waste water is sent to the anammox biofilm tank, and the anammox biofilm tank is equipped with a biofilm anammox reactor. The ammonia nitrogen and nitrite produced in the nitrification tank are converted into nitrogen gas, and a small amount of nitrate produced in the reaction process flows into the sulfur autotrophic denitrification tank. The sulfur autotrophic denitrification tank is equipped with an autotrophic denitrification reactor, and the autotrophic denitrification reaction The device uses the sulfide in the subsequent desulfurization tank to convert nitrate into nitrogen, and simulta...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap