Large-plate transmission and density control structure of knitting hosiery machine

A technology of density control and sock knitting machine, which is applied in knitting, weft knitting, textile and papermaking, etc., can solve the problems of difficulty in replacement, maintenance and disassembly of the density control system, complex structure of the density control system, and difficulty in processing, etc. The effect of reducing the production cost and maintenance cost of the whole machine, simple structure, and reduced processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

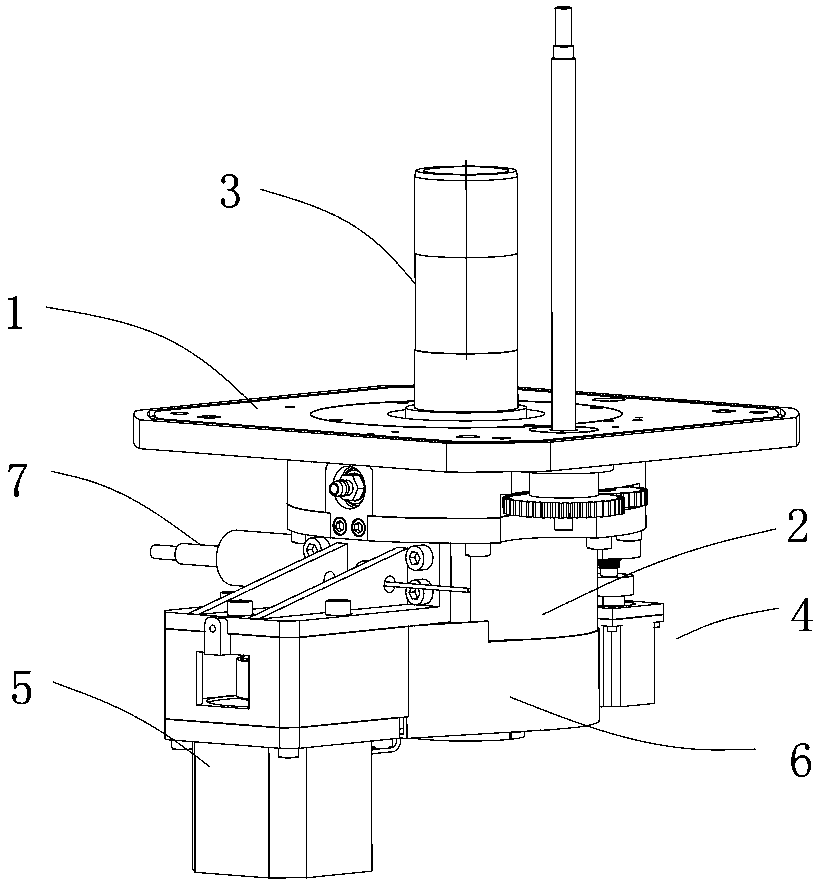

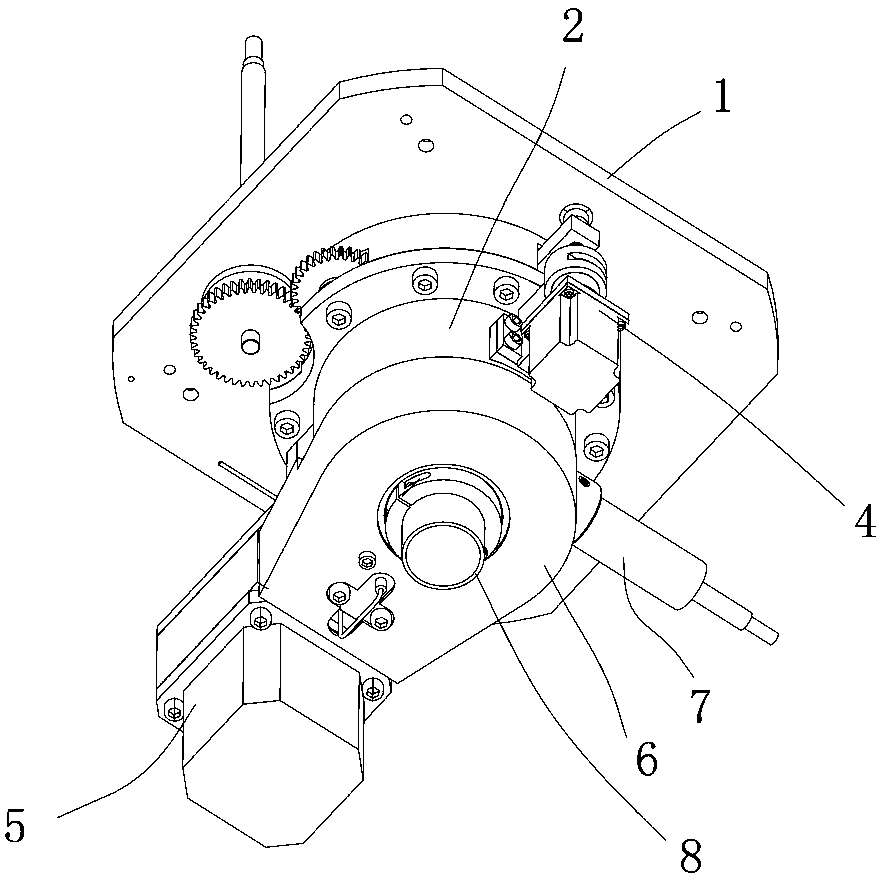

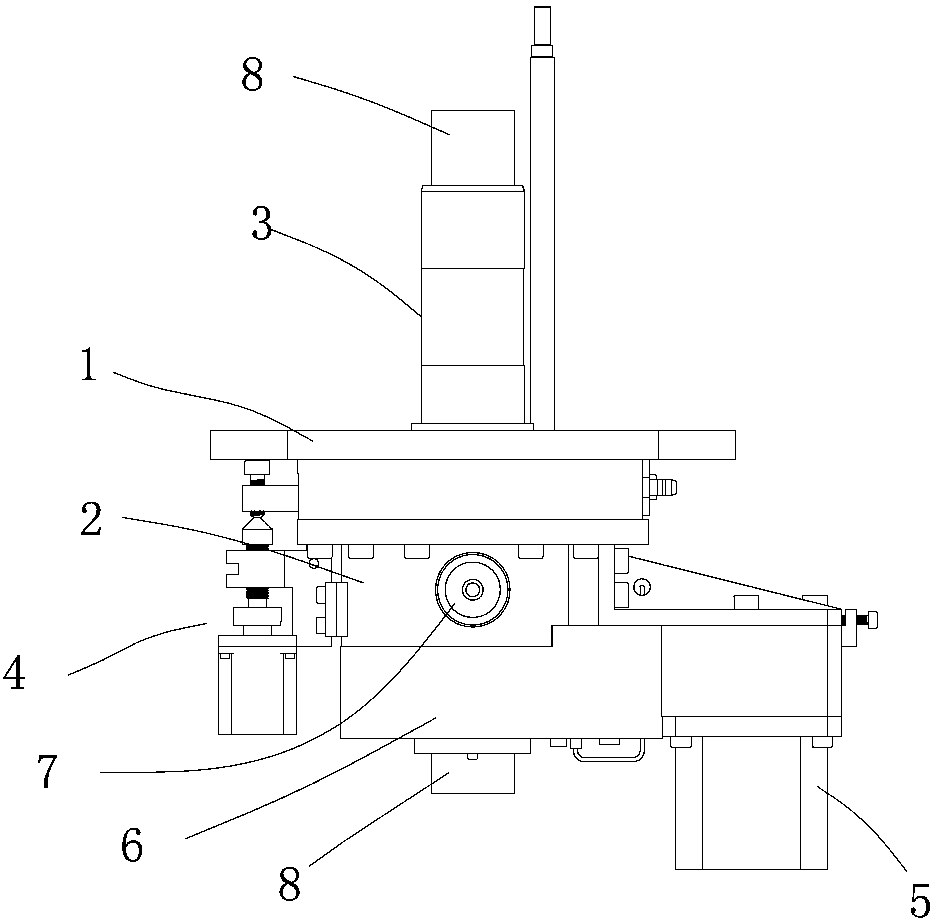

[0028] Embodiment: a kind of large plate transmission and density control structure of hosiery machine, such as Figure 1 to Figure 3 shown. The device includes a chassis 1, a large bearing base 2 is fixedly connected to the lower end of the chassis, a syringe core 3 is arranged in the large bearing base, an upper bearing 22 is arranged on the upper part of the large bearing base, and a lower bearing 23 is arranged on the lower part. The bearing and the lower bearing can rotatably support the syringe core 3 . The inner sleeve of the syringe core is provided with a sock tube 8, and the upper end of the syringe core is pierced to the top of the chassis 1. The upper and lower ends of the sock tube 8 are all longer than the syringe core, and the sock tube is fixedly arranged and does not rotate with the syringe core.

[0029] Such as Figure 4 , 6, 7, and 8, the underside of the chassis 1 and the top of the upper bearing 22 are provided with a large density adjustment ring 9, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap