Fabricated buckling restraint supporting component

A technology of buckling restraint and supporting components, which is applied in the direction of building components, building structures, protective buildings/shelters, etc., can solve the problems of increasing structural load, long processing time, inconvenience in construction, transportation and installation, and achieve reduction The effect of maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

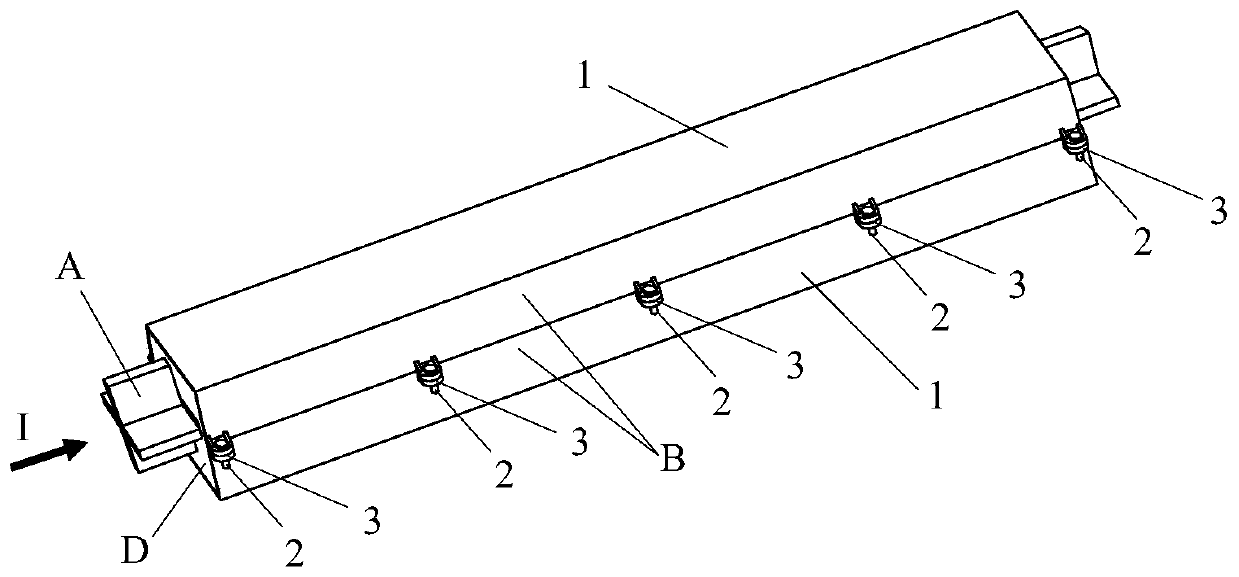

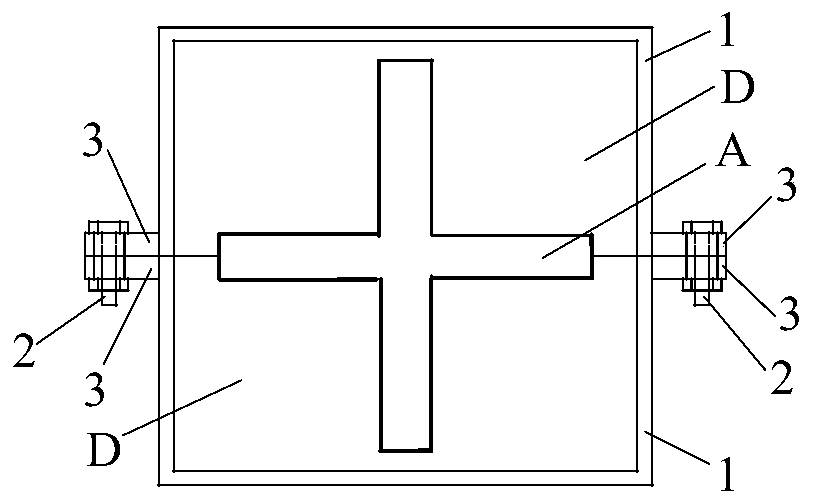

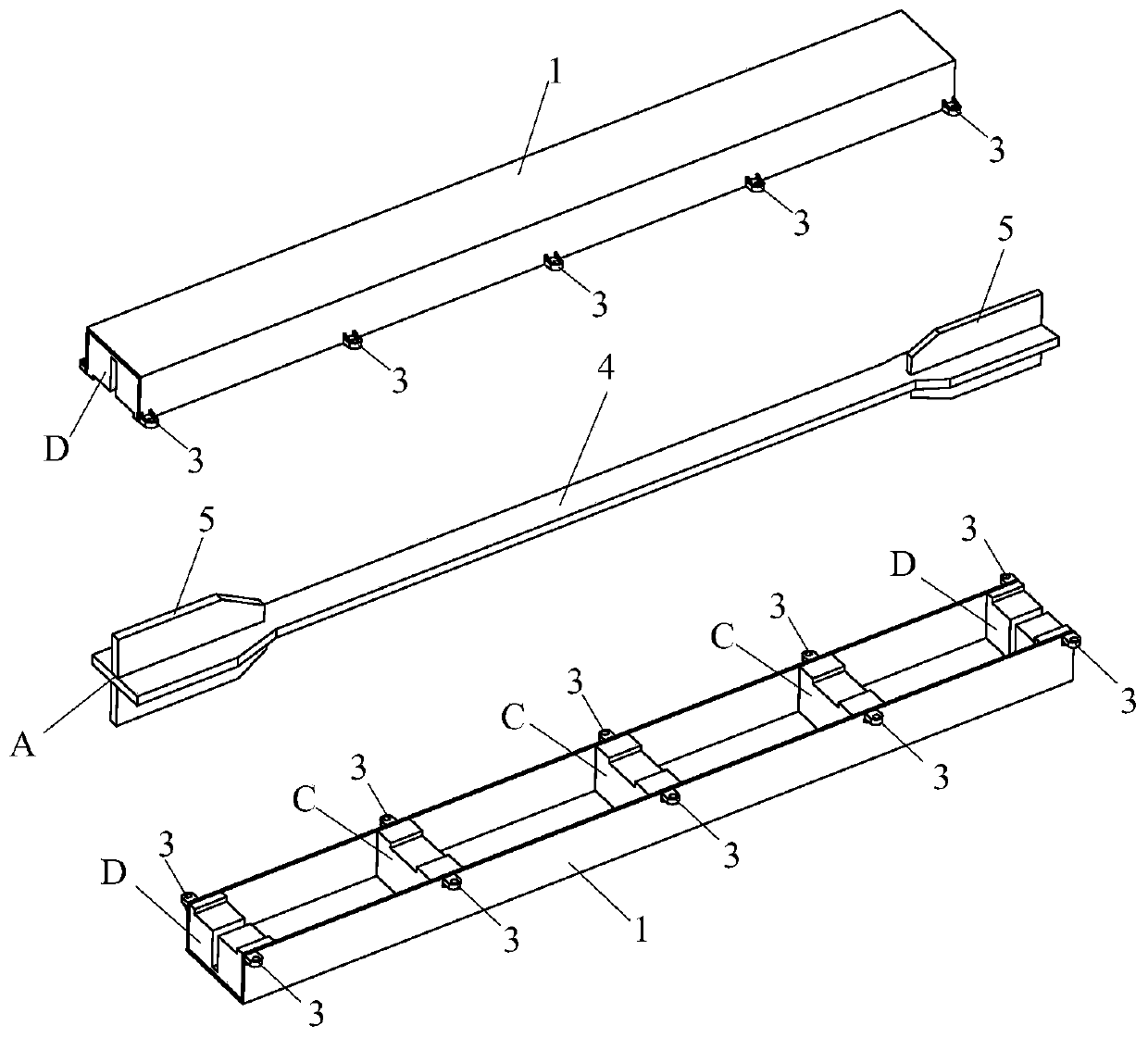

[0025] see Figure 1-8 , this embodiment 1 includes a core unit A, an outer restraint steel pipe B, an inner restraint card C and an end restraint card D, and the outer restraint steel pipe B is assembled by connecting two identical half steel pipes 1 through a bolt connection pair 2 , there are several pairs of internal constraint cards C, which are equidistantly arranged in pairs in the two half-side steel pipes 1, and the specific number is determined by the length of the core unit A and calculated according to the pressure bar stability theory to ensure that the core unit is not free from The compression buckling is determined. There are two pairs of the end restraints D, which are arranged at both ends of the two half steel pipes 1. The internal restraint C and the end restraint D are welded to the two half steel pipes 1. connected.

[0026] A pair of lug plates 3 are welded on the outer sides of the two edges of the two half-side steel pipes 1 corresponding to the inter...

Embodiment 2

[0032] see Figure 1-2 , Figure 7-9 , this embodiment 2 is basically the same as embodiment 1, the difference is that the section of the working section 4 of the core unit is cross-shaped, and the shape and size of the corresponding internal constraint card notch 6 match the section shape and size of the working section 4 of the core unit.

Embodiment 3

[0034] see Figure 10 , Figure 11 , this embodiment 3 is basically the same as embodiment 1, the difference is that the cross-section of the outer restraint steel pipe B is circular, and the outer contour shape and size of the corresponding inner restraint card C and end restraint card D are the same as the internal shape and size of the half steel pipe 1 match.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com