A centrifugal slag discharge type radial piston chuck, power head and drilling rig

A technology of centrifugal slag discharge and power head, applied in drill pipe, drill pipe, earthwork drilling, etc., can solve the problems of easy accumulation of rock powder, slow response of chuck opening, etc., and achieve easy maintenance, simple structure and reliability. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1. Centrifugal slag discharge type radial piston chuck:

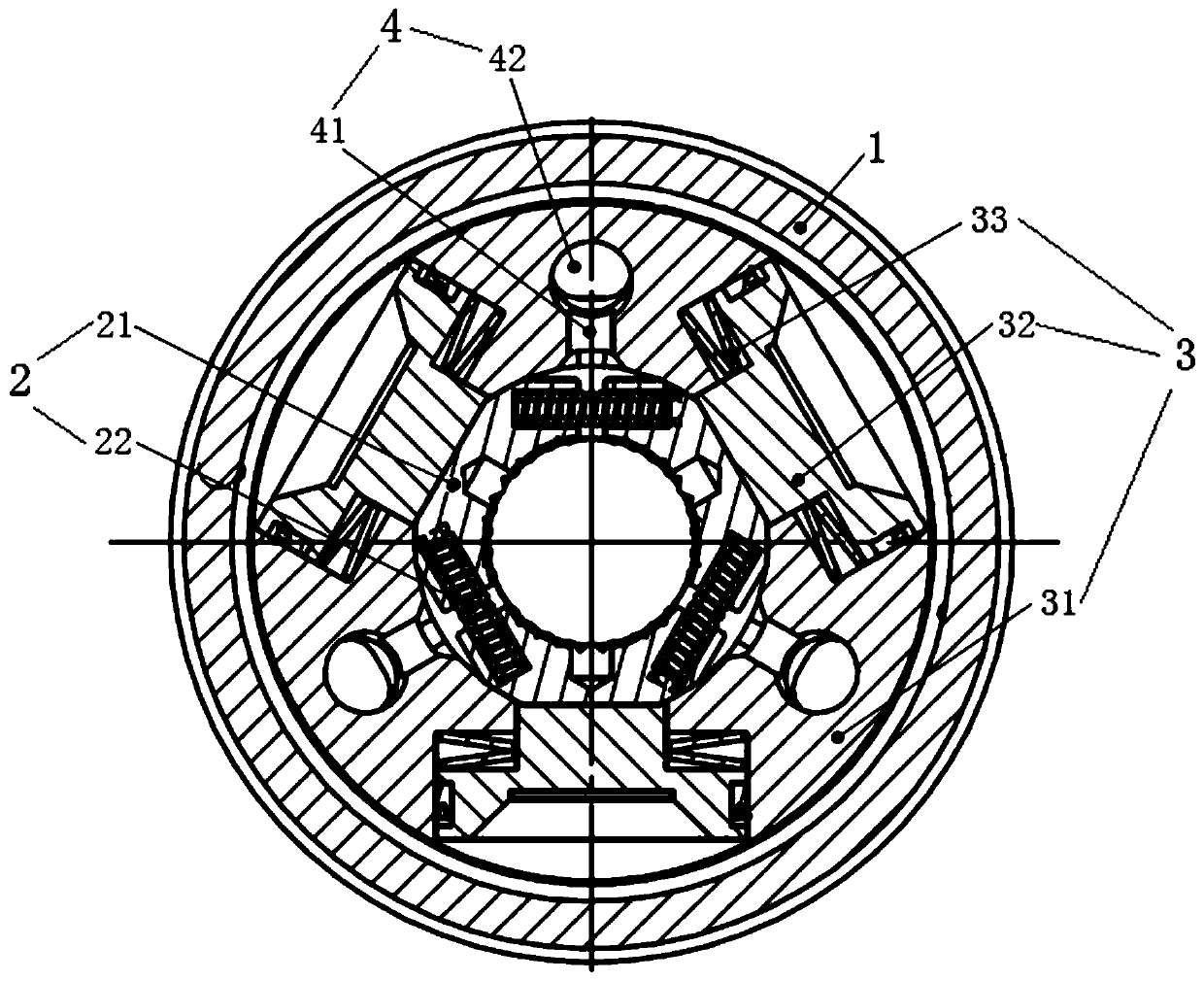

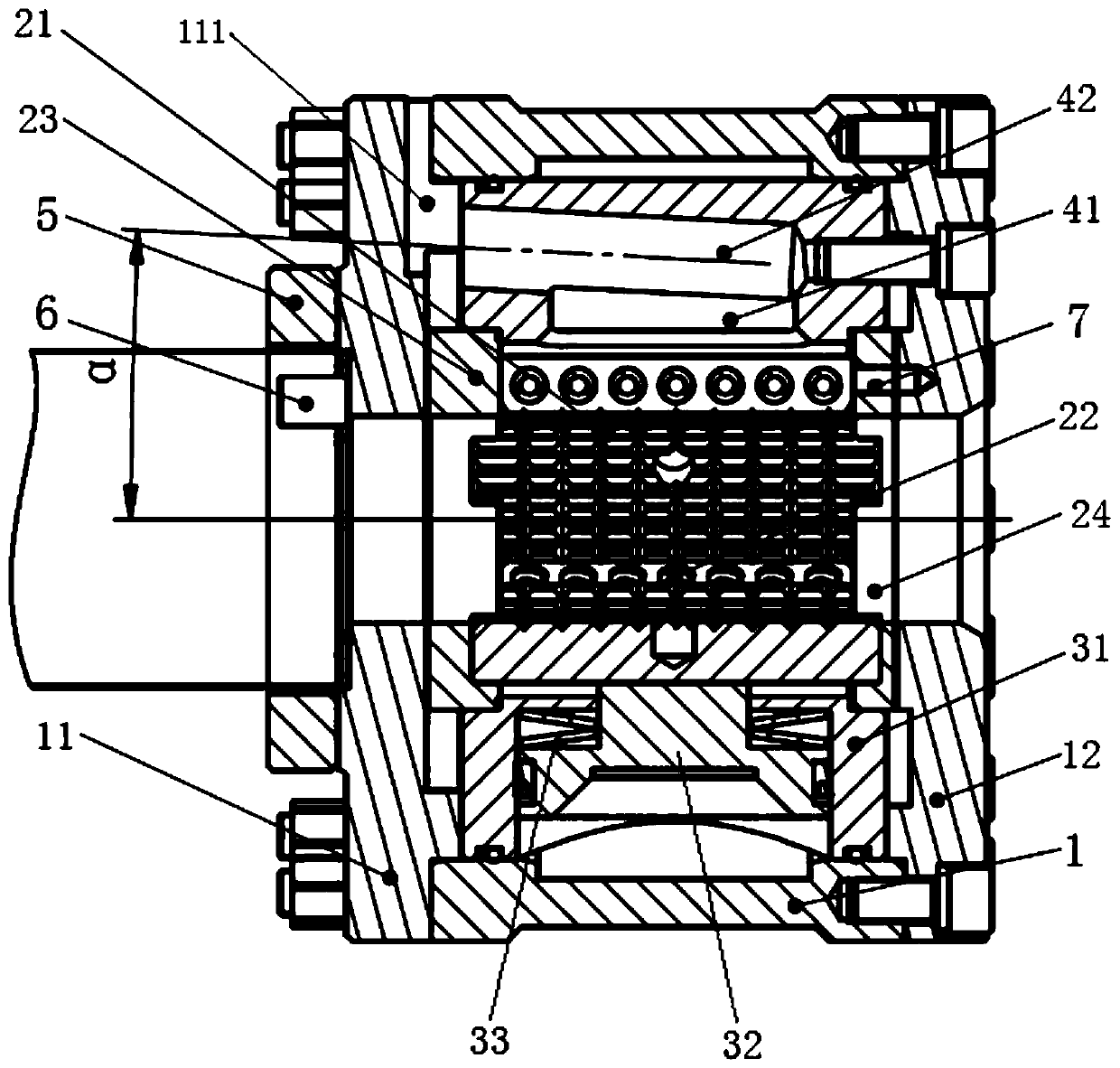

[0046] combine figure 1 and figure 2 , the centrifugal slag discharge type radial piston chuck of the present embodiment includes a chuck body 1, a slip assembly 2 and a radial power assembly 3 are arranged radially in the chuck body 1, and a radial power assembly 3 is arranged along the shaft A centrifugal slag discharge combination chamber 4 is provided in the direction of the rotating centrifugal force, connecting the slip assembly 2 with the external space.

[0047] The slip assembly 2 is provided with three groups of slips 21 along the circumferential direction for clamping the drill pipe; a return spring 22 is provided between adjacent slips 21; the radial power assembly 3 includes a radial oil cylinder 31 and a radial piston 32 And the disc spring 33, the outer middle planes of the three slips 21 are respectively in contact with the ends of the three radial pistons 32, and the three radial pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com