Feeding bottle drying device for neonatology department

A neonatology and drying device technology, applied in the field of medical devices, can solve the problems that affect the user experience of the milk bottle drying device, the working efficiency of the milk bottle drying device is low, and the time consumption is long, so as to improve the use experience and reduce the consumption. time, increase work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

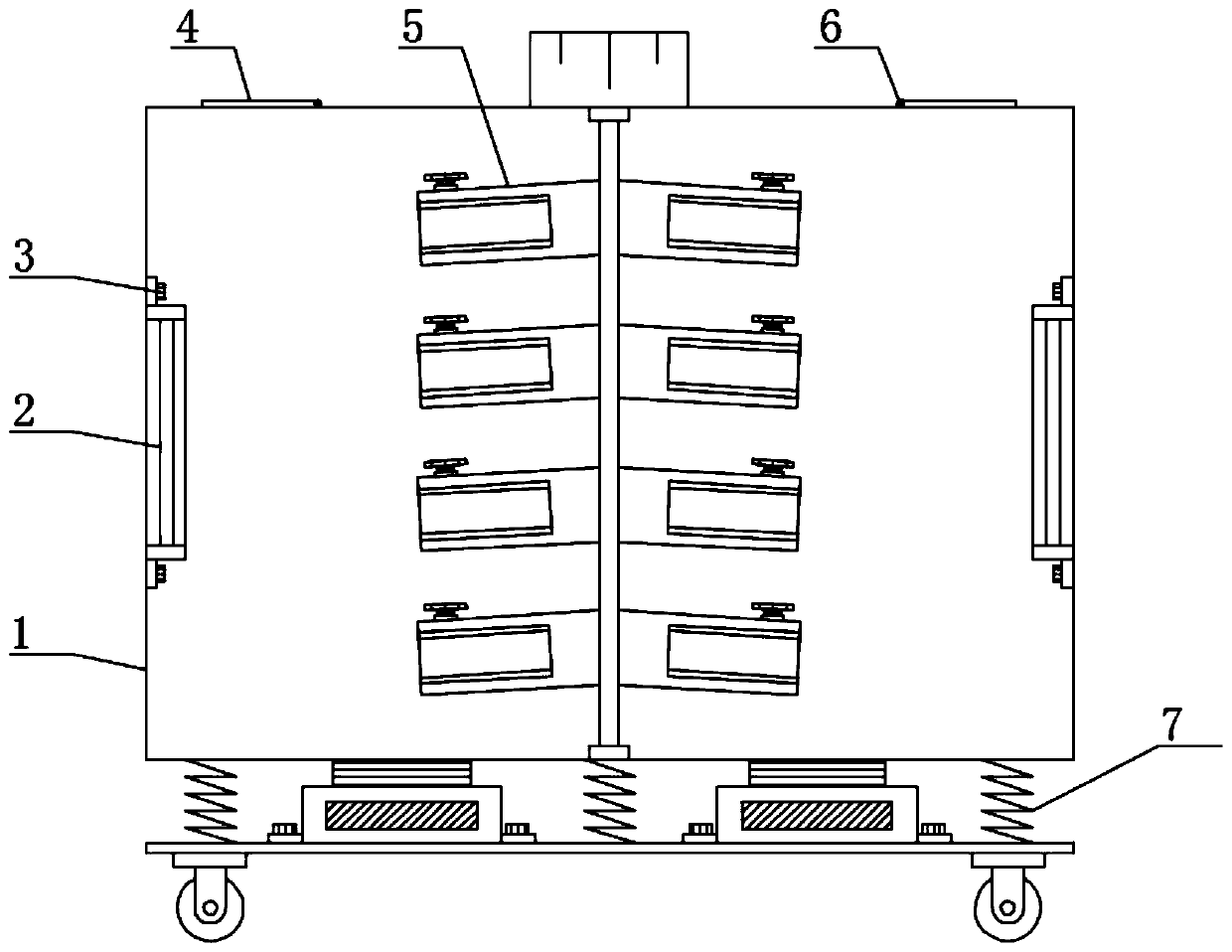

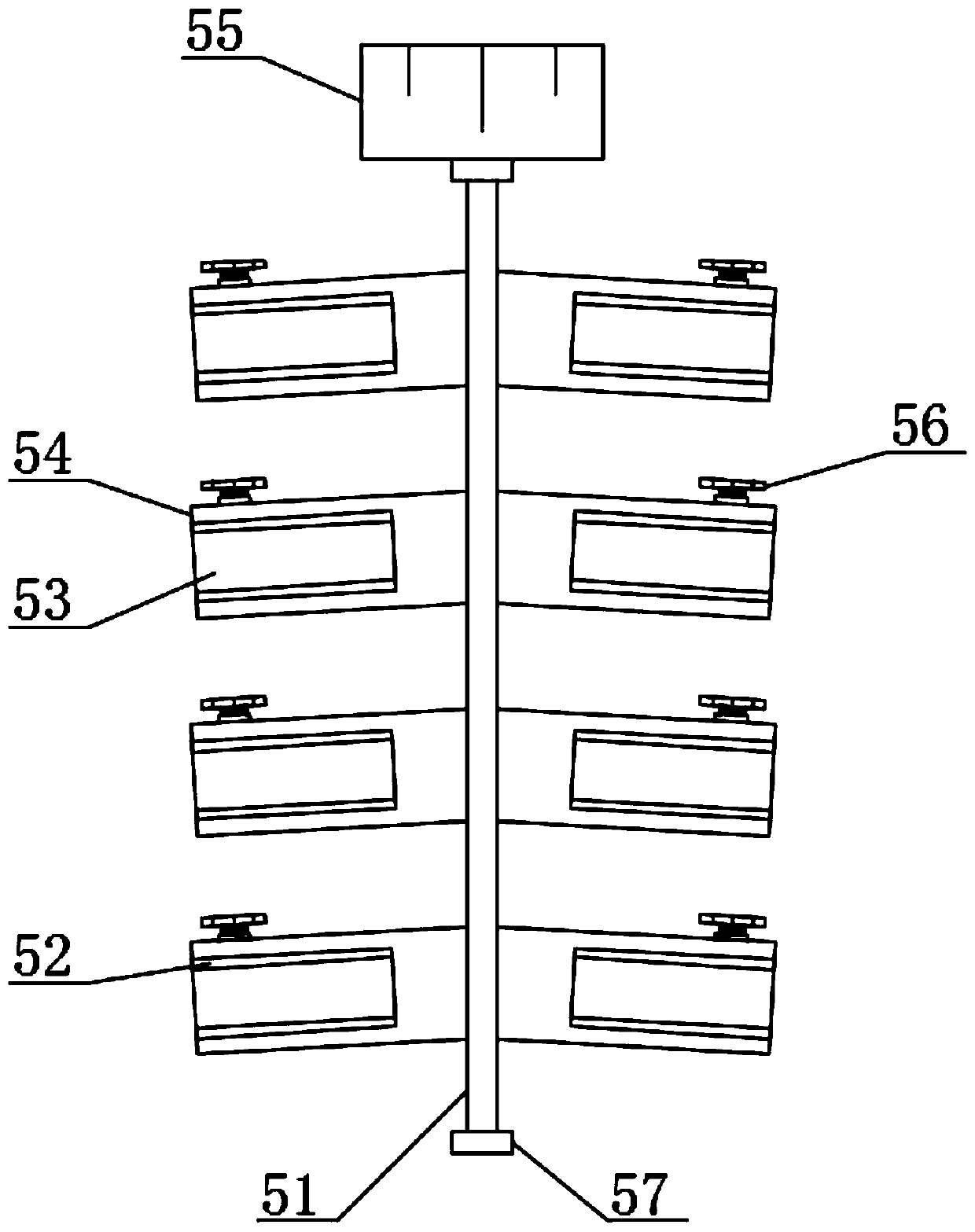

[0022] see Figure 1-Figure 3 , the present invention provides a technical solution: a baby bottle drying device for neonatology, comprising a drying box 1, an ultraviolet disinfection lamp 2, a drying mechanism 5 and a shock absorbing mechanism 7, and the two ends of the upper surface of the drying box 1 are arranged There is a cover plate 4, a hinge 6 is welded at the junction of the drying box 1 and the cover plate 4, and a drying mechanism 5 is arranged on the top of the drying box 1, and the drying mechanism 5 includes a motor 55, which is fixed on the In the middle position of the upper surface of the drying box 1, the output end of the motor 55 is provided with a transmission rod 51, and the both sides of the transmission rod 51 are provided with a limit sleeve 54, and a limit groove 53 is provided on the limit sleeve 54, and the limit sleeve 54 is provided with an adjusting bolt 56 at one end away from the transmission rod 51;

[0023] In order to make the fixing effe...

Embodiment 2

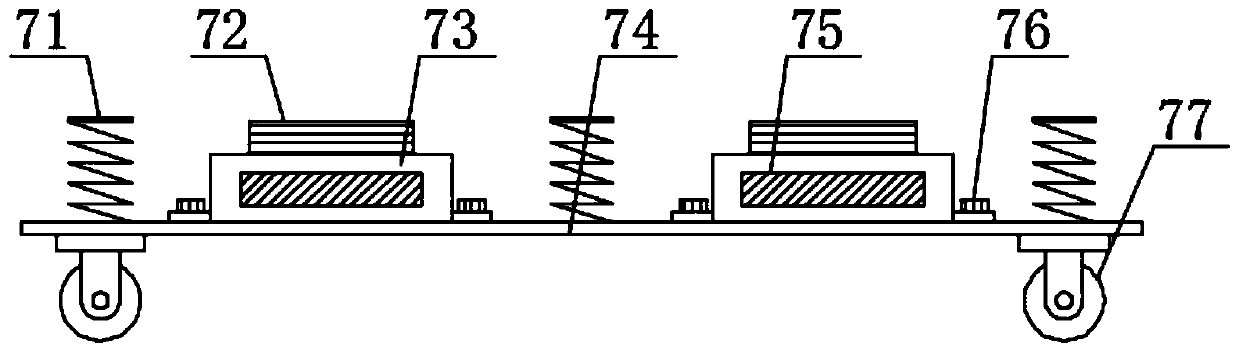

[0027] see Figure 1-Figure 3 , on the basis of embodiment 1, in order to make the shock absorption effect of the feeding bottle drying device better, in this embodiment, preferably, the bottom of the drying box 1 is provided with a shock absorbing mechanism 7, and the shock absorbing mechanism 7 includes a supporting bottom plate 74. A damping spring 71 is welded at the connection between the support base plate 74 and the drying box 1, and the damping spring 71 converts the received kinetic energy into its own elastic potential energy, thereby playing a damping role;

[0028] In order to make the drying effect of the baby bottle drying device better, in this embodiment, preferably, the two ends of the upper surface of the supporting base plate 74 are provided with hot air blowers 73, and the hot air blowers 73 are fixed on the supporting base plate 74 by the second screws 76 at both ends. Above, the connection between the hot air blower 73 and the drying box 1 is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com