Workshop manufacturing system multi-target scheduling method based on time-assigned Petri network

A technology for manufacturing systems and scheduling methods, applied in manufacturing computing systems, comprehensive factory control, data processing applications, etc., can solve problems such as no method and program implementation, and achieve the effect of speeding up and reducing the size of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

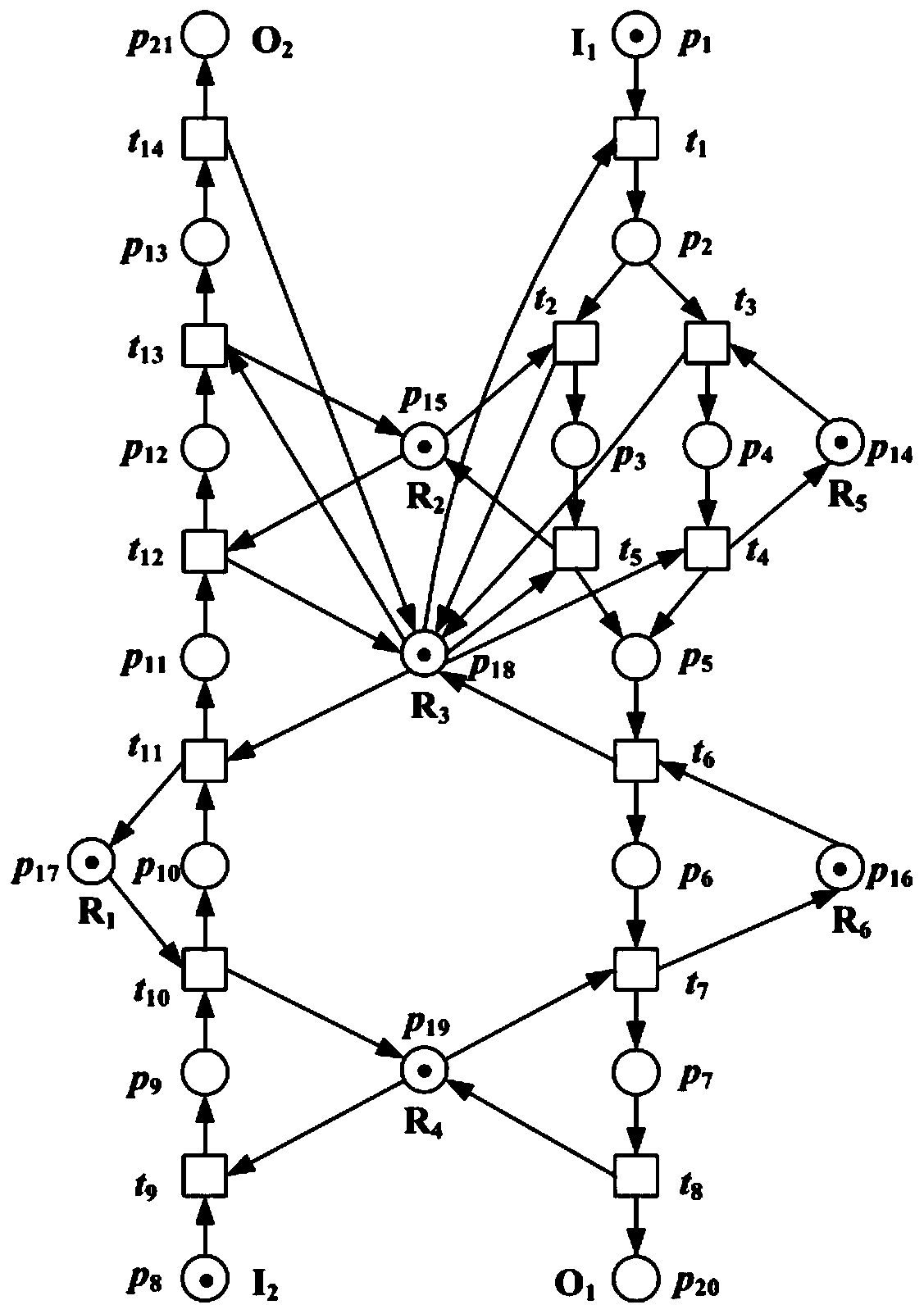

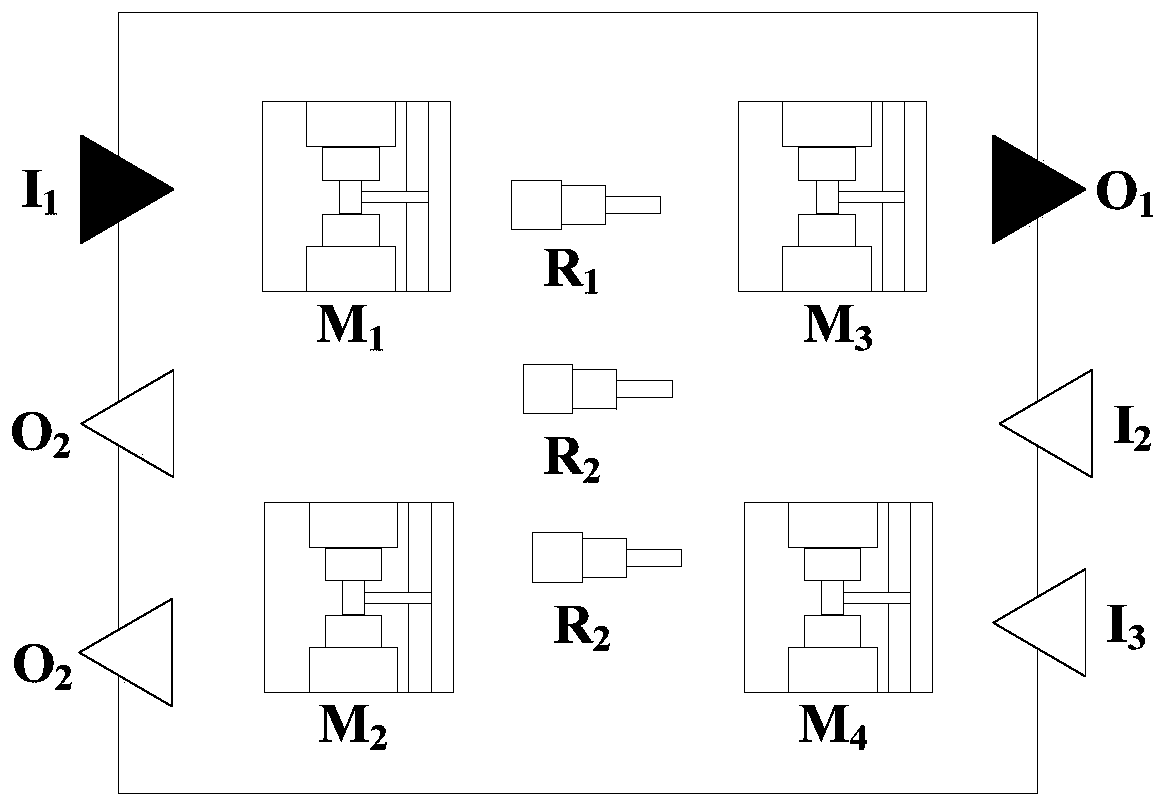

[0058] The example of the multi-objective workshop manufacturing system adopted in this embodiment is image 3 shown, including three robots (R 1 , R 2 , R 3 : Each robot can hold one product at the same time) and four machines (M 1 , M 2 , M 3 , M 4 : Each machine can process two products at the same time), and three input buffers (I 1 ,I 2 ,I 3 ) and three output buffers (O 1 ,O 2 ,O 3 ). The system is mainly divided into three production lines with three robots as the core, and its operation process is as follows:

[0059] J 1 : I 1 →R 1 → M 1 →R 2 → M 2 →R 3 →O 1

[0060] or I 1 →R 1 → M 3 →R 2 → M 4 →R 3 →O 1

[0061] J 2 : I 2 →R 2 → M 2 →R 2 →O 2

[0062] J 3 : I 3 →R 3 → M 4 →R 2 → M 3 →R 1 →O 3

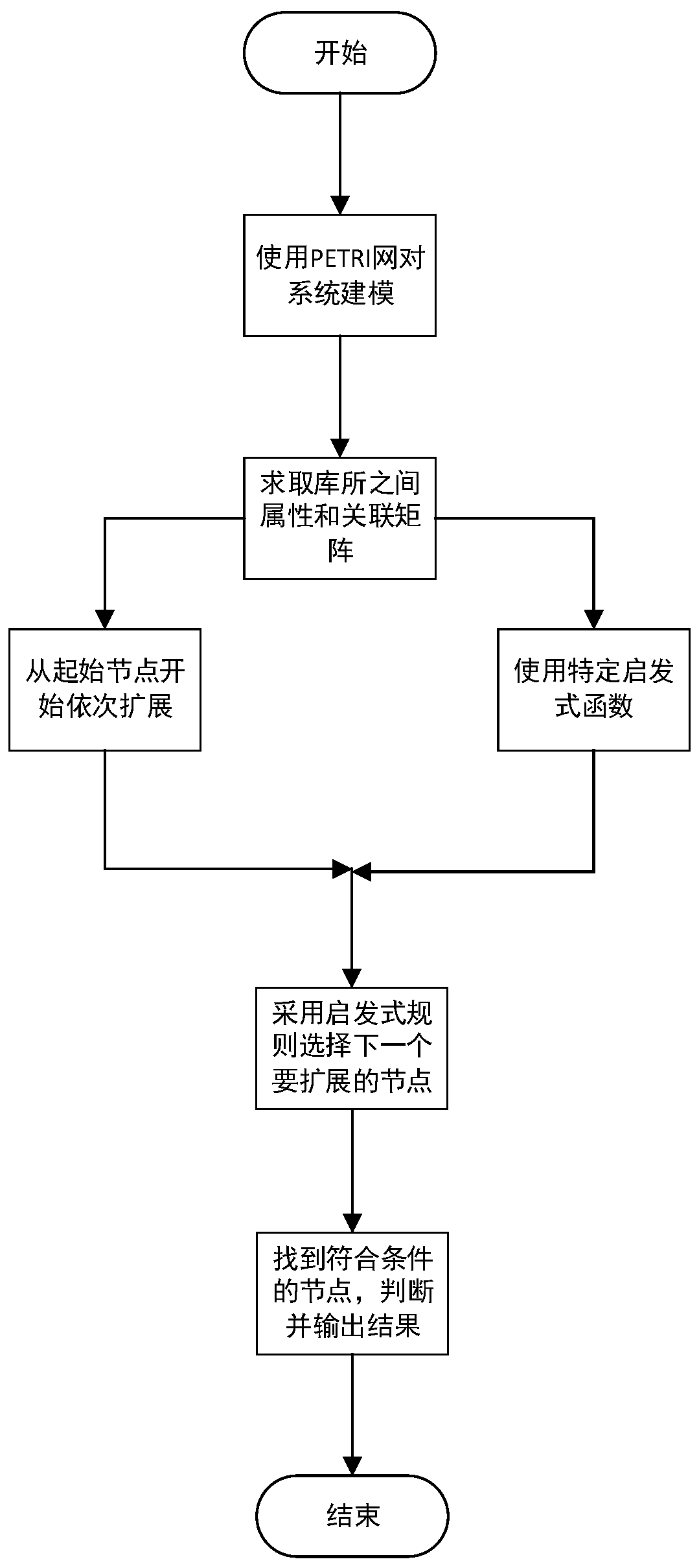

[0063] The present invention is based on the workshop manufacturing system multi-objective scheduling method of timed Petri net, comprises the following content:

[0064] 1. Use the Petri network pair image 3 The workshop manufa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com