Array substrate and preparation method thereof

A technology for an array substrate and a base substrate, which is applied to the field of array substrates and their preparation, can solve the problems of complex ion implantation process and other problems, and achieve the effect of reducing the ion implantation process and alleviating the complexity of the ion implantation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] Aiming at the problems of complex ion implantation process and high production cost in the existing array substrate, the present invention provides a preparation method of the array substrate to alleviate this problem.

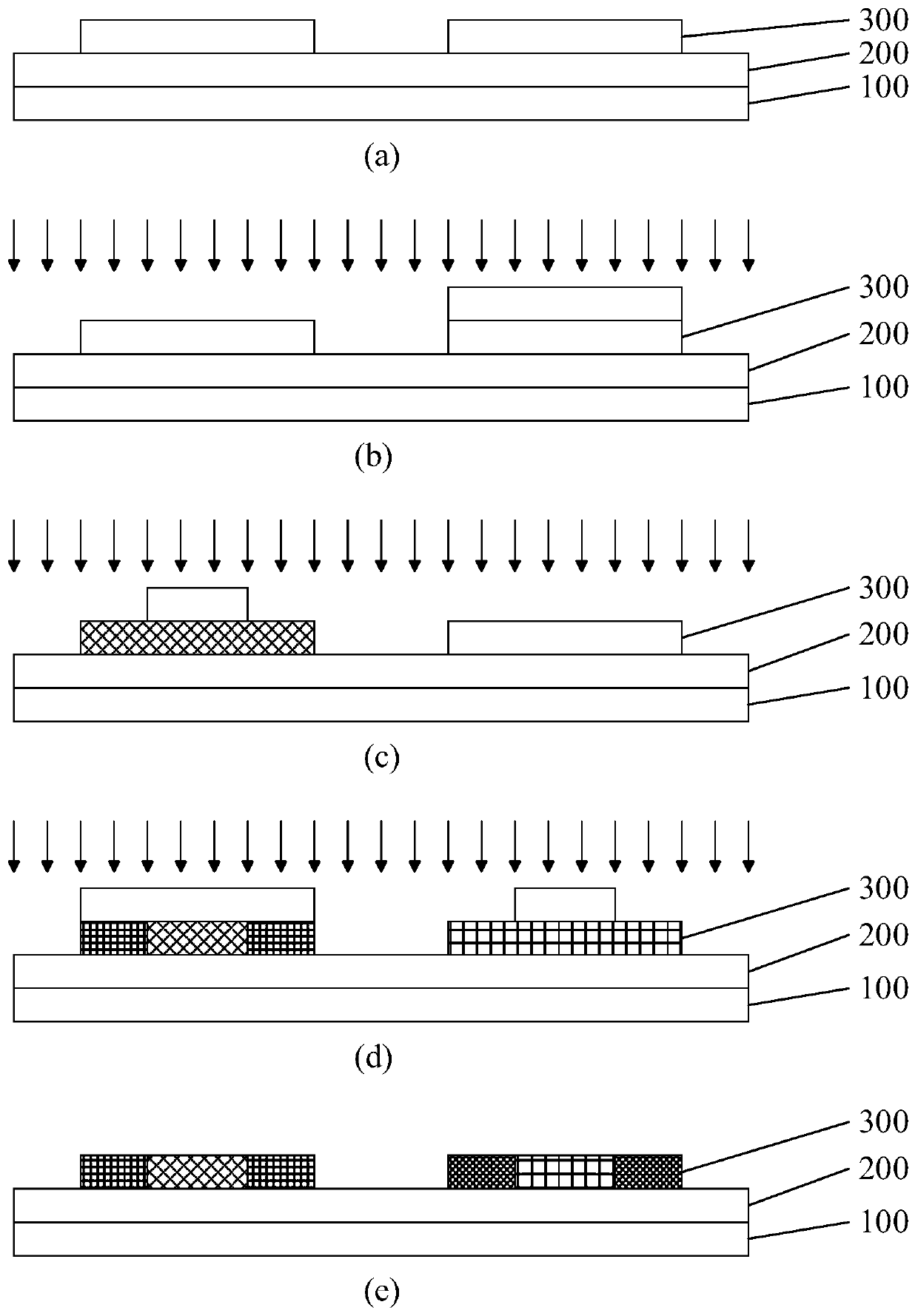

[0031] In one embodiment, as figure 2 As shown, the steps of the preparation method of the array substrate provided by the present invention include:

[0032] S1. Provide a base substrate, on which a first polysilicon layer corresponding to a first type thin film transistor and a second polysilicon layer corresponding to a second type thin film transistor are prepared, the first polysilicon layer The crystalline silicon layer and the second polysilicon layer are arranged in the same layer;

[0033] S2. Prepare a photoresist layer on the polysilicon layer, the thickness of the photoresist layer corresponding to the gate region of the second type thin film transistor is greater than the thickness of the photoresist layer in other regions;

[0034] S3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com