Device and method for controlling multi-die power module

A power module and multi-core technology, which is applied in the field of temperature devices, can solve problems such as limiting the effectiveness of parallel devices, uneven aging of tube cores, and uneven temperature distribution of tube cores.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

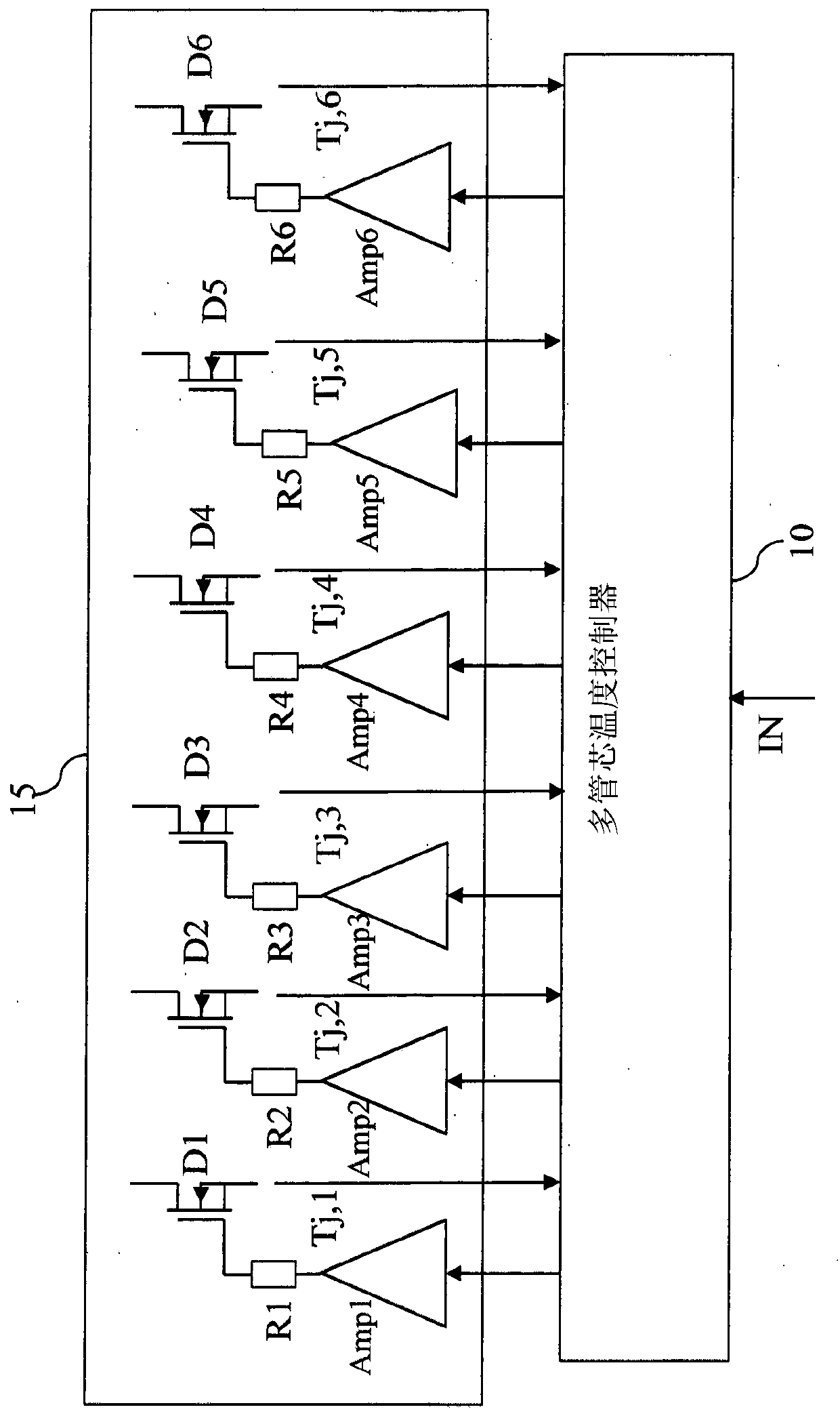

[0043] figure 1 An example of a multi-die power module controlled by a multi-die temperature control device according to the present invention is shown.

[0044] The multi-die power module 15 includes N dies. exist figure 1 In the example of , N is equal to 6.

[0045] The multi-die temperature control device 10 receives an input signal IN and independently drives the dies D1 to D6 through corresponding amplifiers AMP1 to AMP6 and gate resistors R1 to R6 .

[0046] The multi-die temperature control device 10 uses closed-loop temperature control, which may be relative or absolute temperature from the dies D1 to D6, to extend the lifetime of the multi-die power module 20 by reducing local hot spot temperatures.

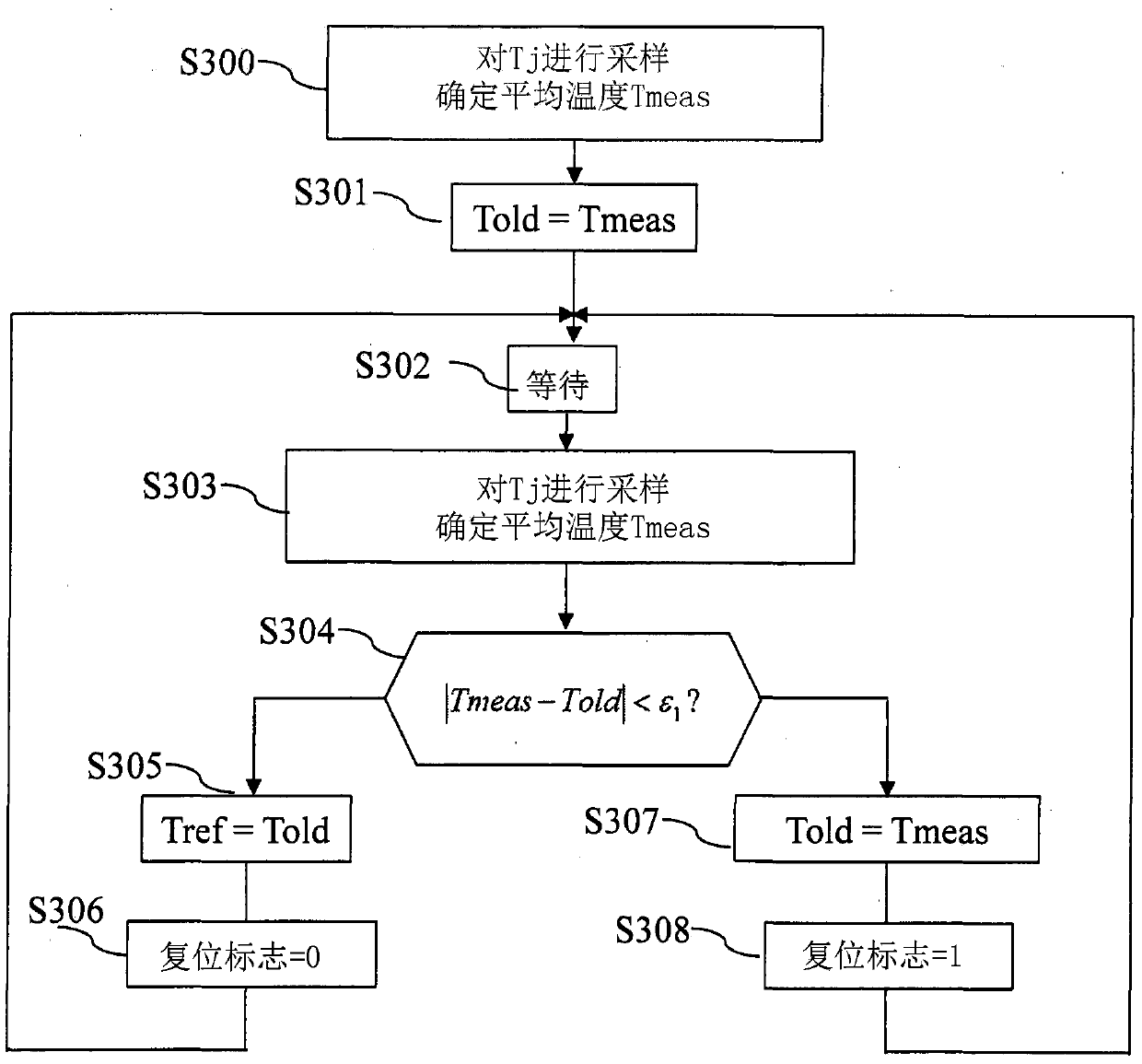

[0047] According to the present invention, the multi-die temperature control unit 10 performs the following steps:

[0048] - determining a first weighted arithmetic mean of the junction temperatures of the dies of the multi-die power module and storing the weighted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com