Quantitative distributing device

A quantitative batching and batching box technology, which is applied to mixers with rotating stirring devices, transportation and packaging, mixer accessories, etc., can solve the problems of poor control of batching and batching residues, so as to avoid multiple operations and speed up Efficiency, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

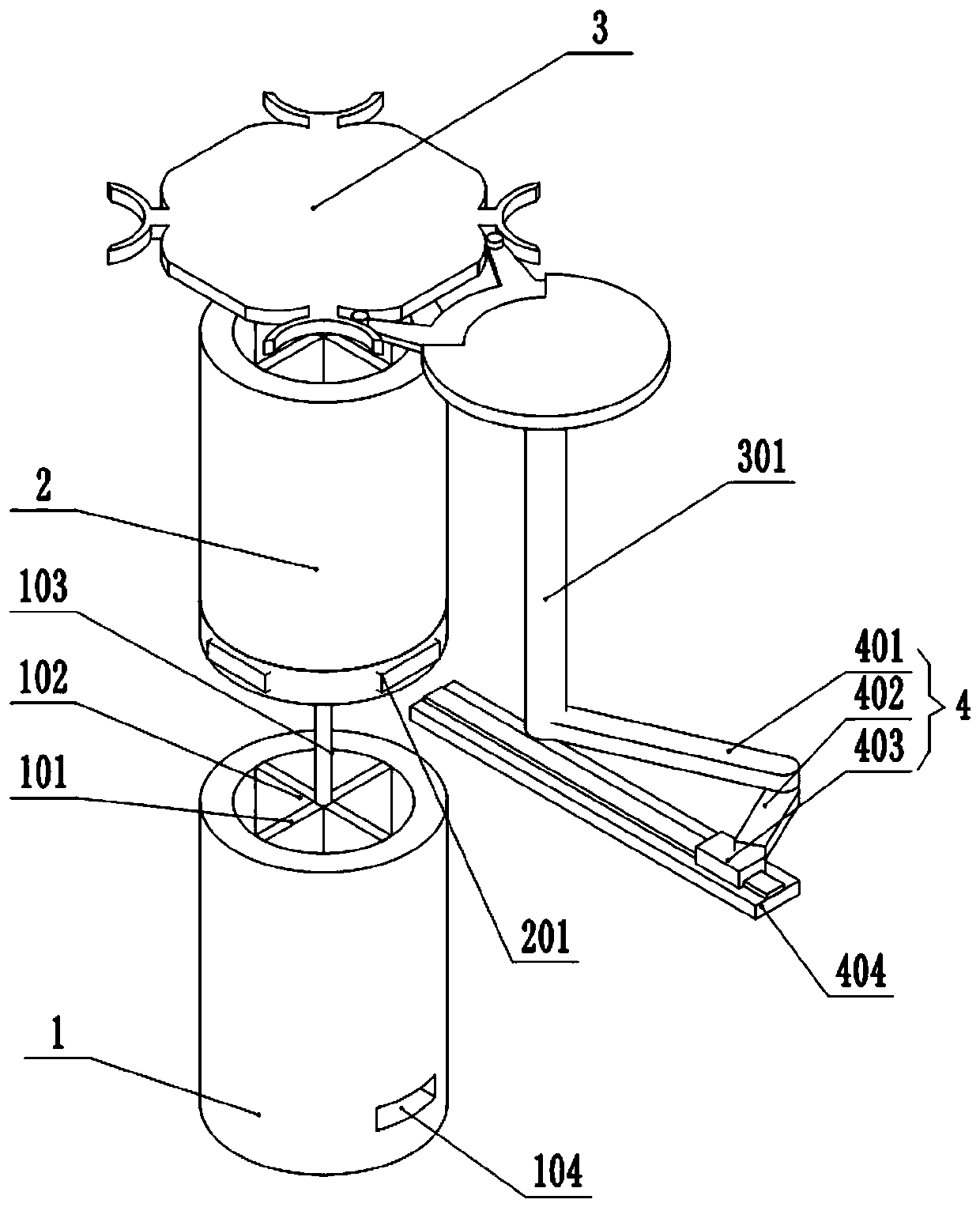

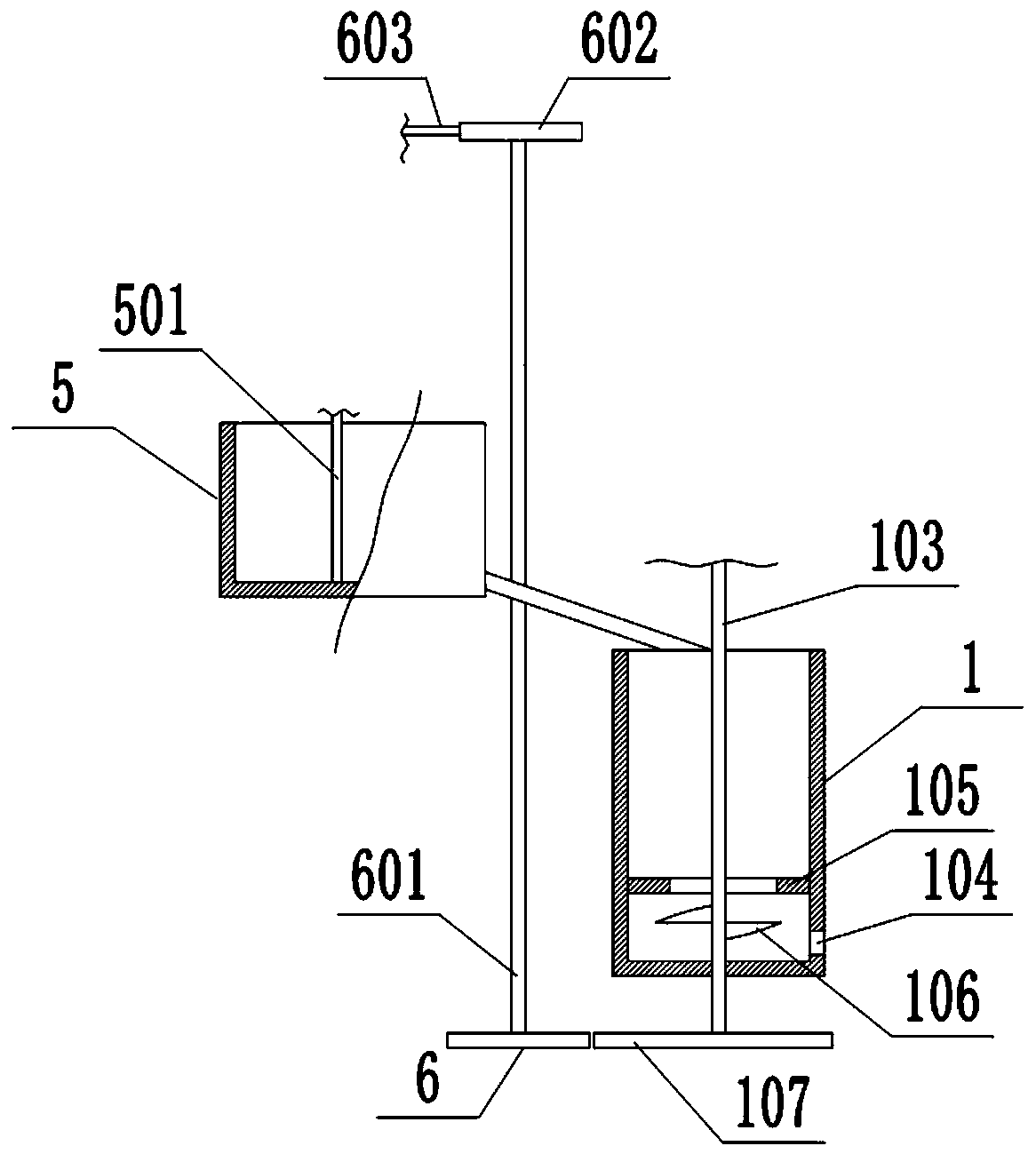

[0038] Dosing devices, such as figure 1 As shown, including a bracket, a working box 1 is fixedly connected to the bracket, a batching box 2 connected to the bracket is arranged above the working box 1, a material discharge port is provided at the bottom of the batching box 2, and a material inlet is provided at the top of the working box 1. The batching box 2 top is provided with an intermittent mechanism, and the intermittent mechanism in the present embodiment is a sheave mechanism 3, and the sheave mechanism 3 comprises a driving turntable and a driven sheave, and a driver fixed on a support is provided above the driving turntable (not shown in the figure). Draw), in the present embodiment, the driving member is a driving motor, and the output shaft of the driving motor is coaxially connected with the top of the driving turntable.

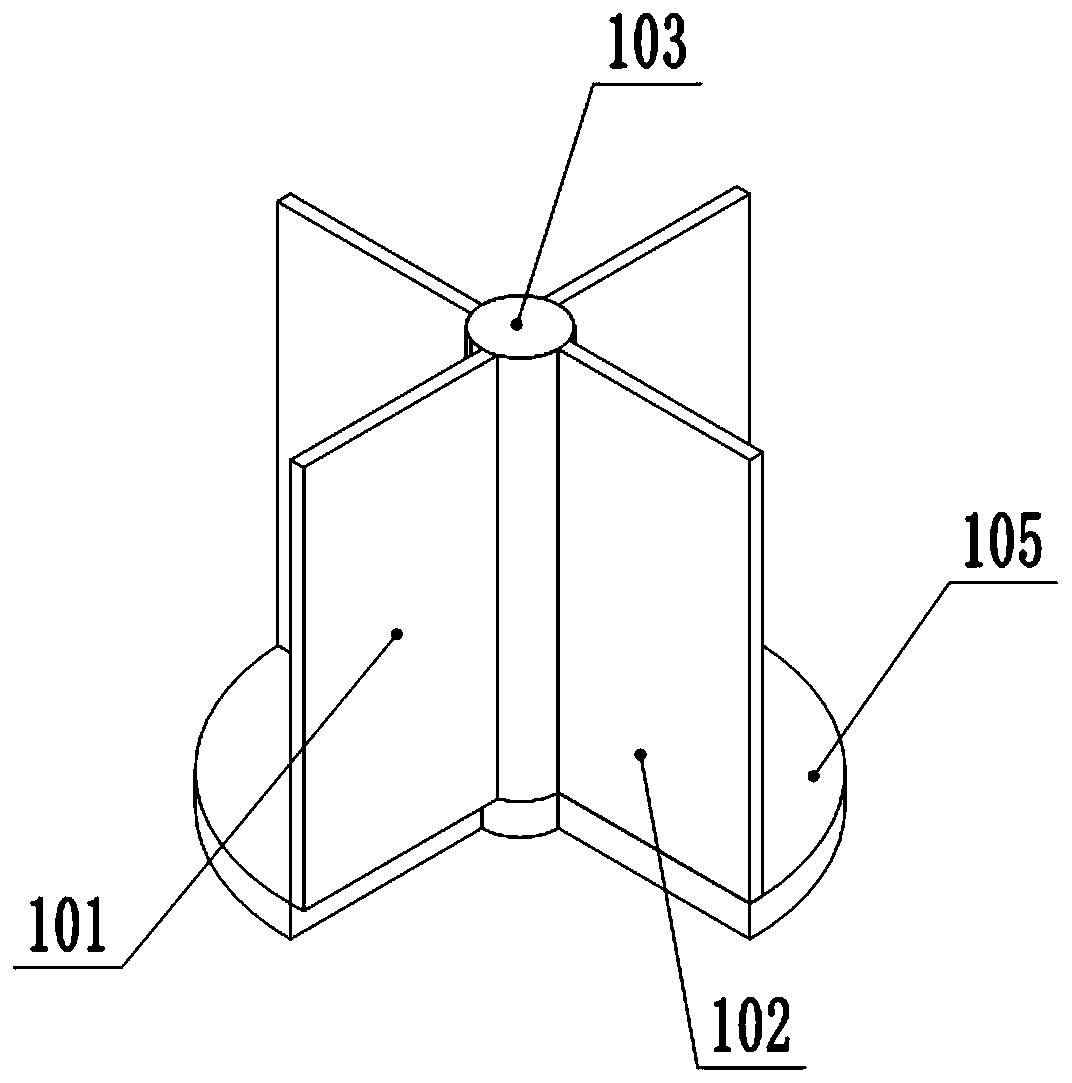

[0039] The size of the working box 1 and the batching box 2 are the same, and both the working box 1 and the batching box 2 are provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com