Oil smoke purification system

An oil fume purification and oil fume technology, which is applied in chemical instruments and methods, external electrostatic separators, electrode structures, etc., can solve the problems of oil fume deposition in oil fume pipes, and achieve the effects of improving purification capacity, avoiding deposition, and ingenious structural design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

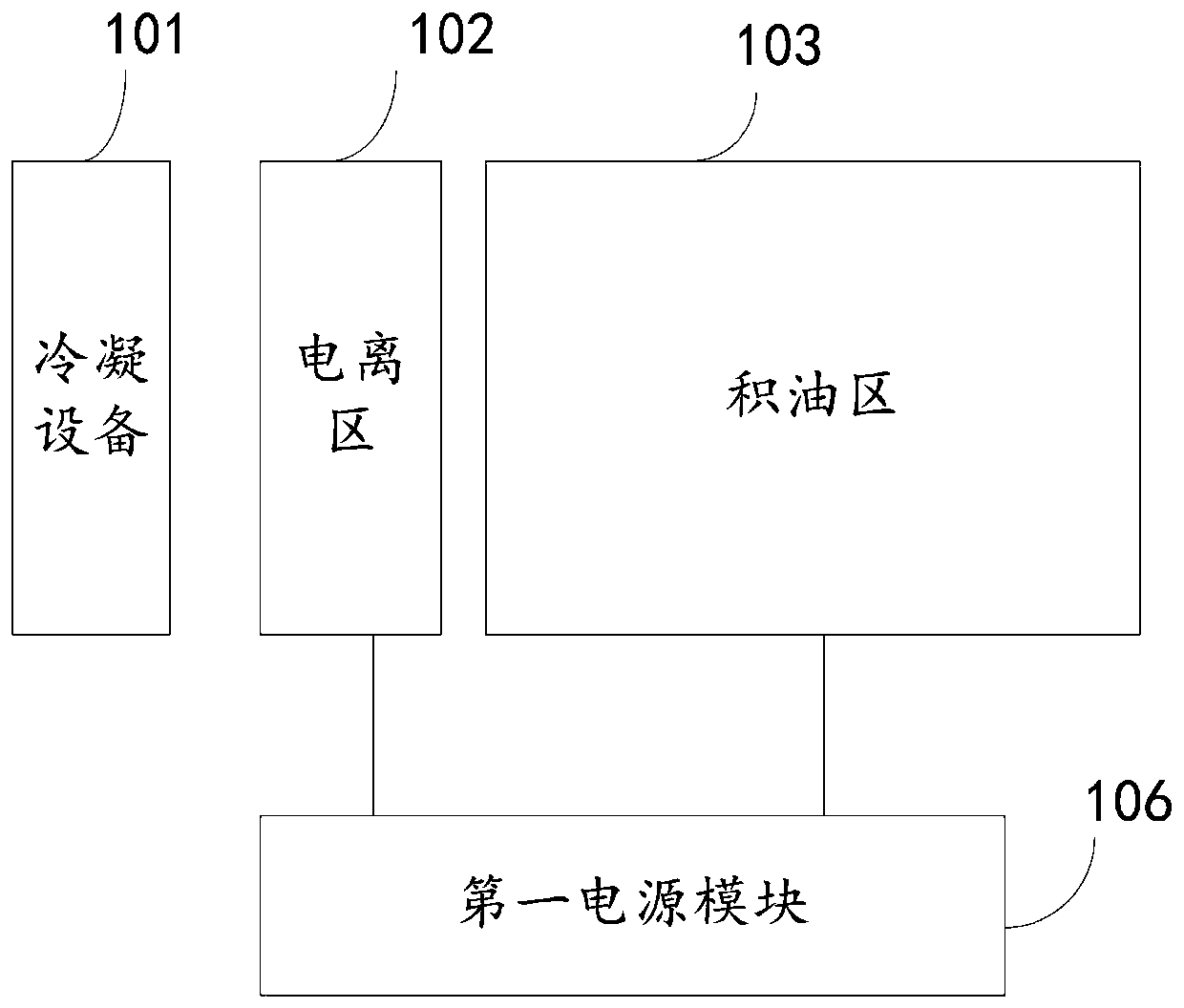

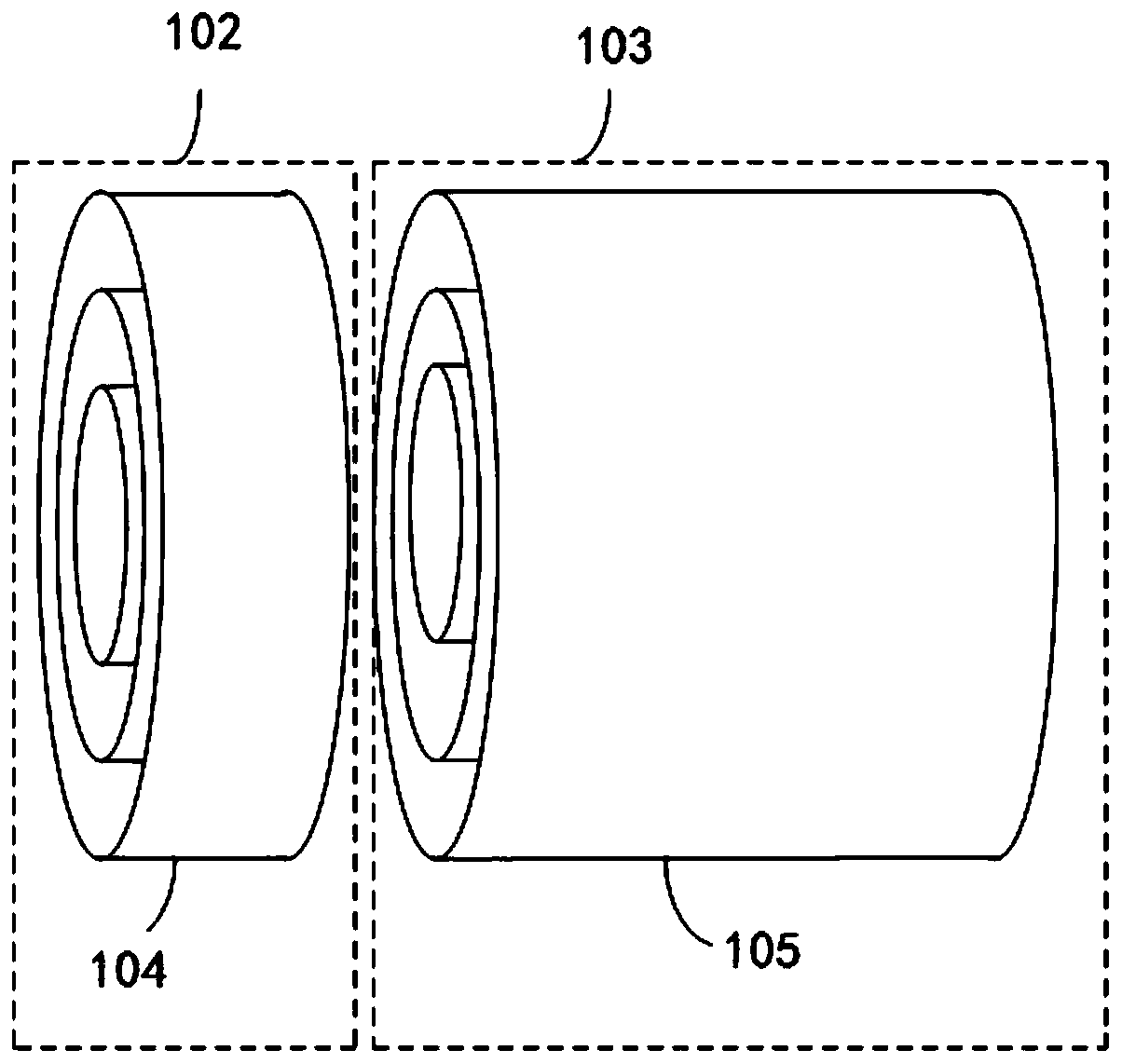

[0050] refer to figure 1 and figure 2 , this embodiment provides an oil fume purification system, including a condensing device 101, an ionization area 102, and an oil accumulation area 103 arranged in sequence;

[0051] The ionization region 102 includes a plurality of first conductive cylinders 104 with open ends, the plurality of first conductive cylinders 104 are arranged concentrically, and a space for air flow to pass is formed between adjacent first conductive cylinders 104;

[0052]The oil accumulation area 103 includes a plurality of second conductive cylinders 105 with openings at both ends, the plurality of second conductive cylinders 105 are arranged concentrically, and a space for airflow to pass is formed between adjacent second conductive cylinders 105;

[0053] The ionization region 102 is used to form a first electric field between adjacent first conductive cylinders 104 under the action of a first voltage;

[0054] The oil accumulation area 103 is used to ...

Embodiment 2

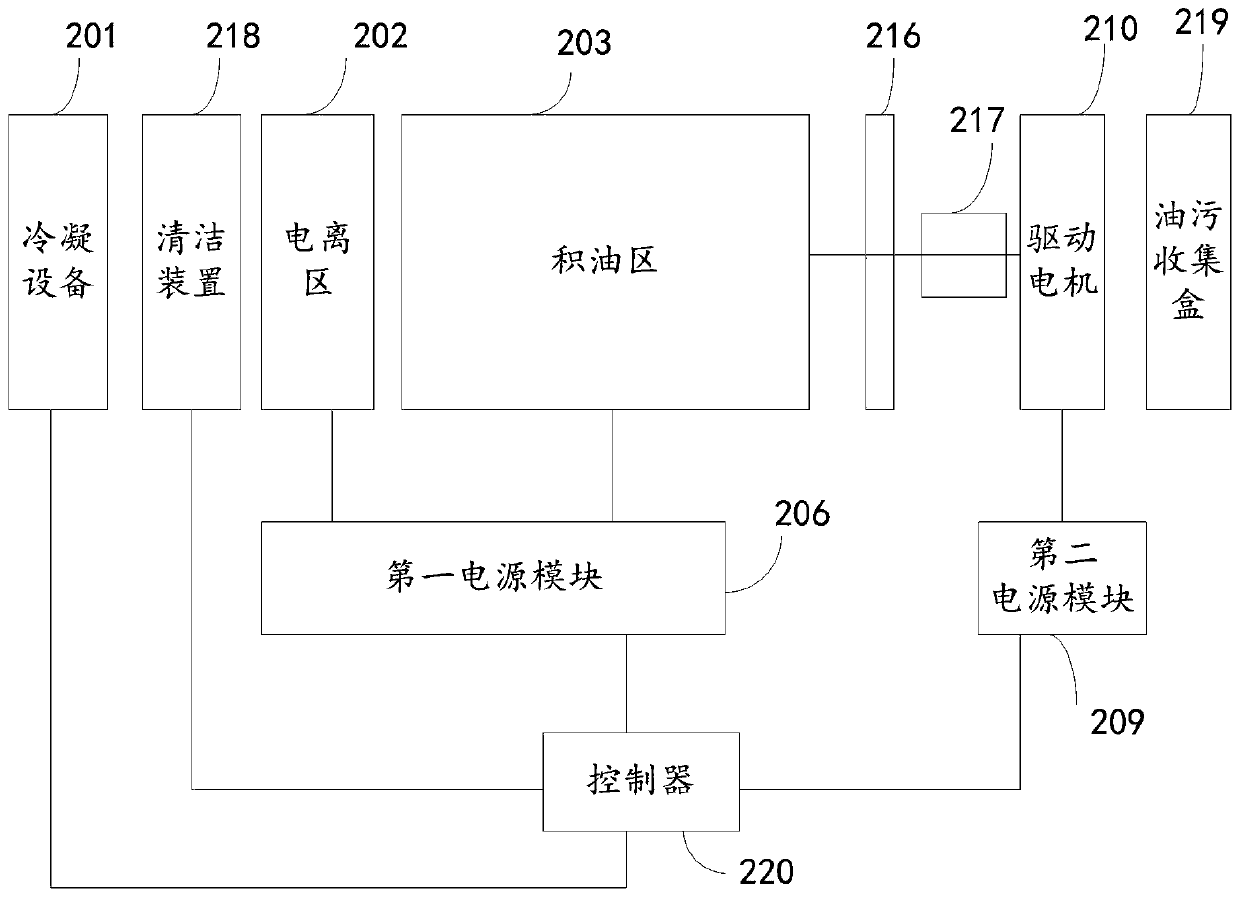

[0072] refer to image 3 , this embodiment provides an oil fume purification system, including a condensation device 201, an ionization area 202, and an oil accumulation area 203;

[0073] The ionization region 202 includes a plurality of first conductive cylinders 204 with open ends, the plurality of first conductive cylinders 204 are arranged concentrically, and a space for airflow to pass is formed between adjacent first conductive cylinders 204;

[0074] The oil accumulation area 203 includes a plurality of second conductive cylinders 205 with openings at both ends, the plurality of second conductive cylinders 205 are arranged concentrically, and a space for airflow to pass is formed between adjacent second conductive cylinders 205;

[0075] The ionization region 202 is used to form a first electric field between adjacent first conductive cylinders 204 under the action of the first voltage;

[0076] The oil accumulation area 203 is used to form a second electric field bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com