Screen printing machine and anti-static mechanism thereof

A screen printing machine, anti-static technology, used in screen printing machines, printing machines, rotary printing machines and other directions, can solve problems such as affecting normal inking and blocking failures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

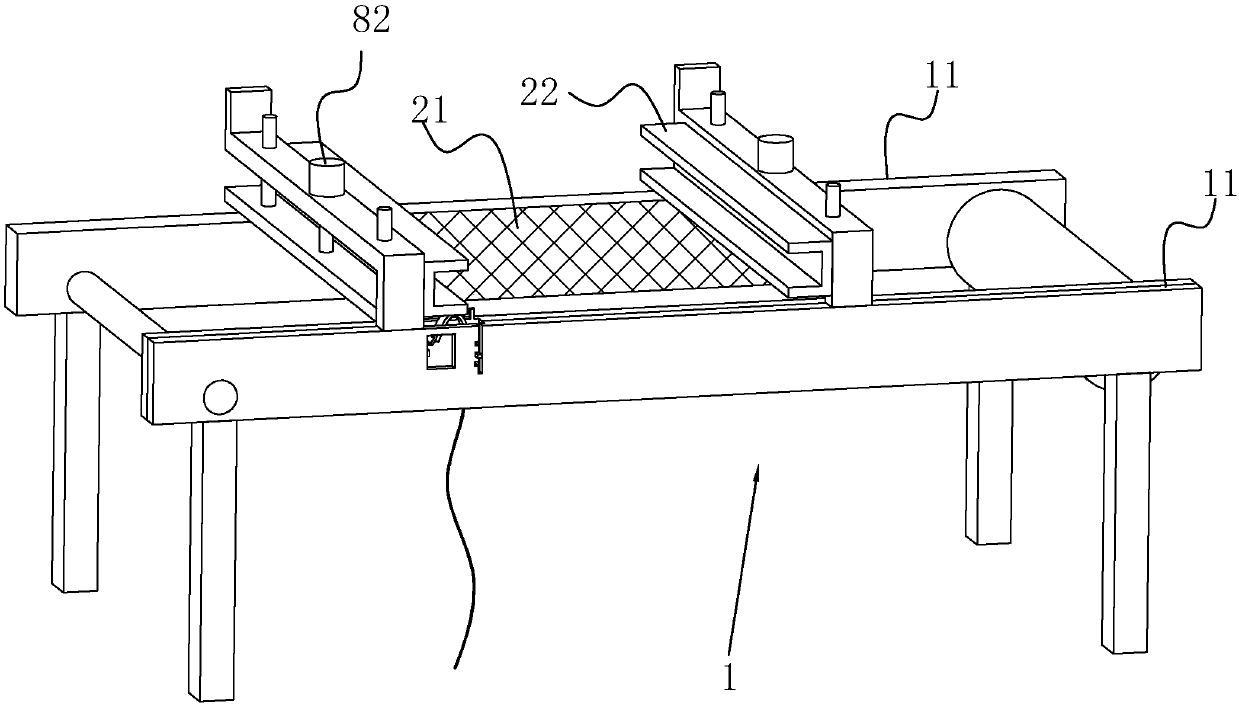

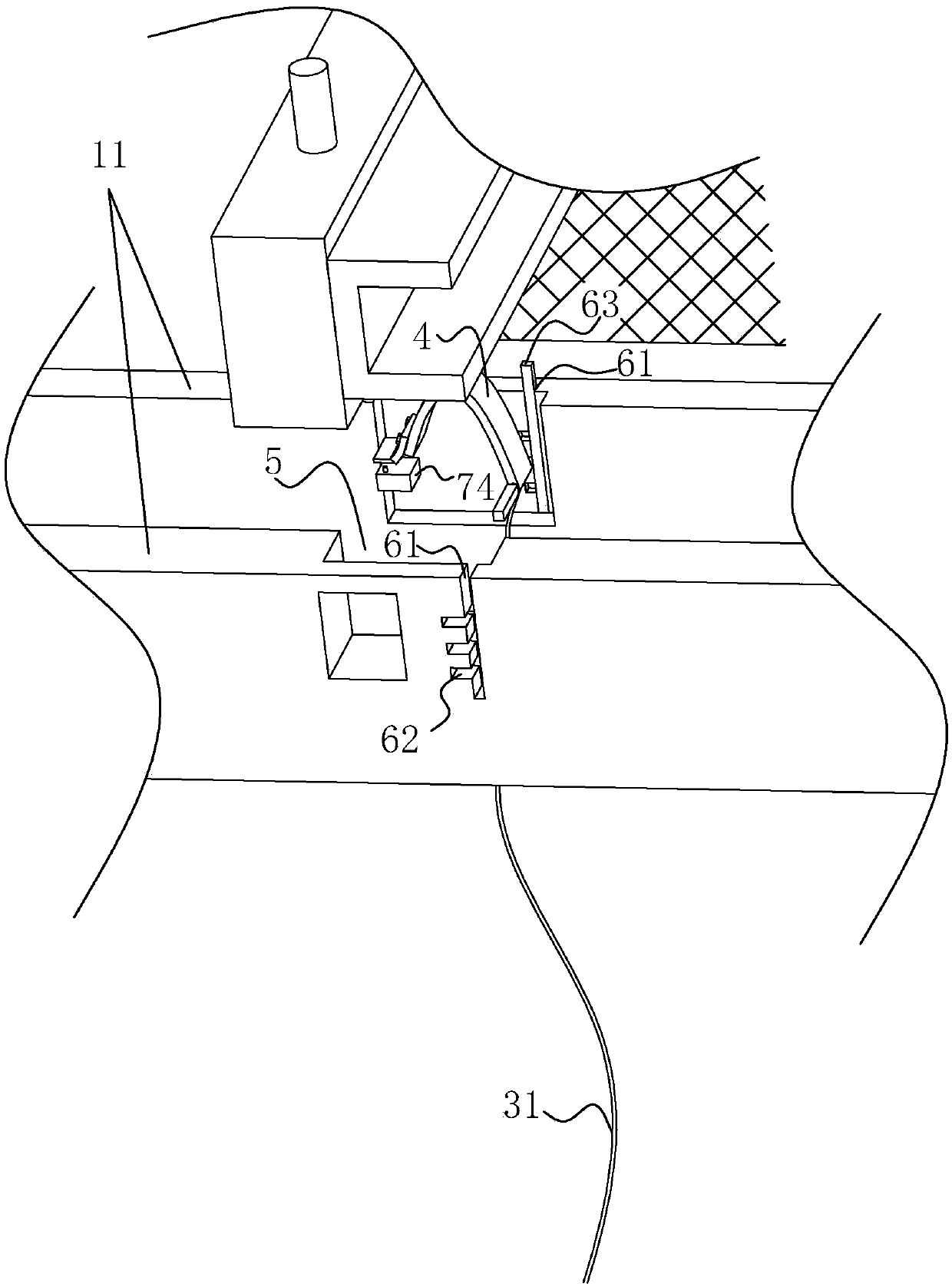

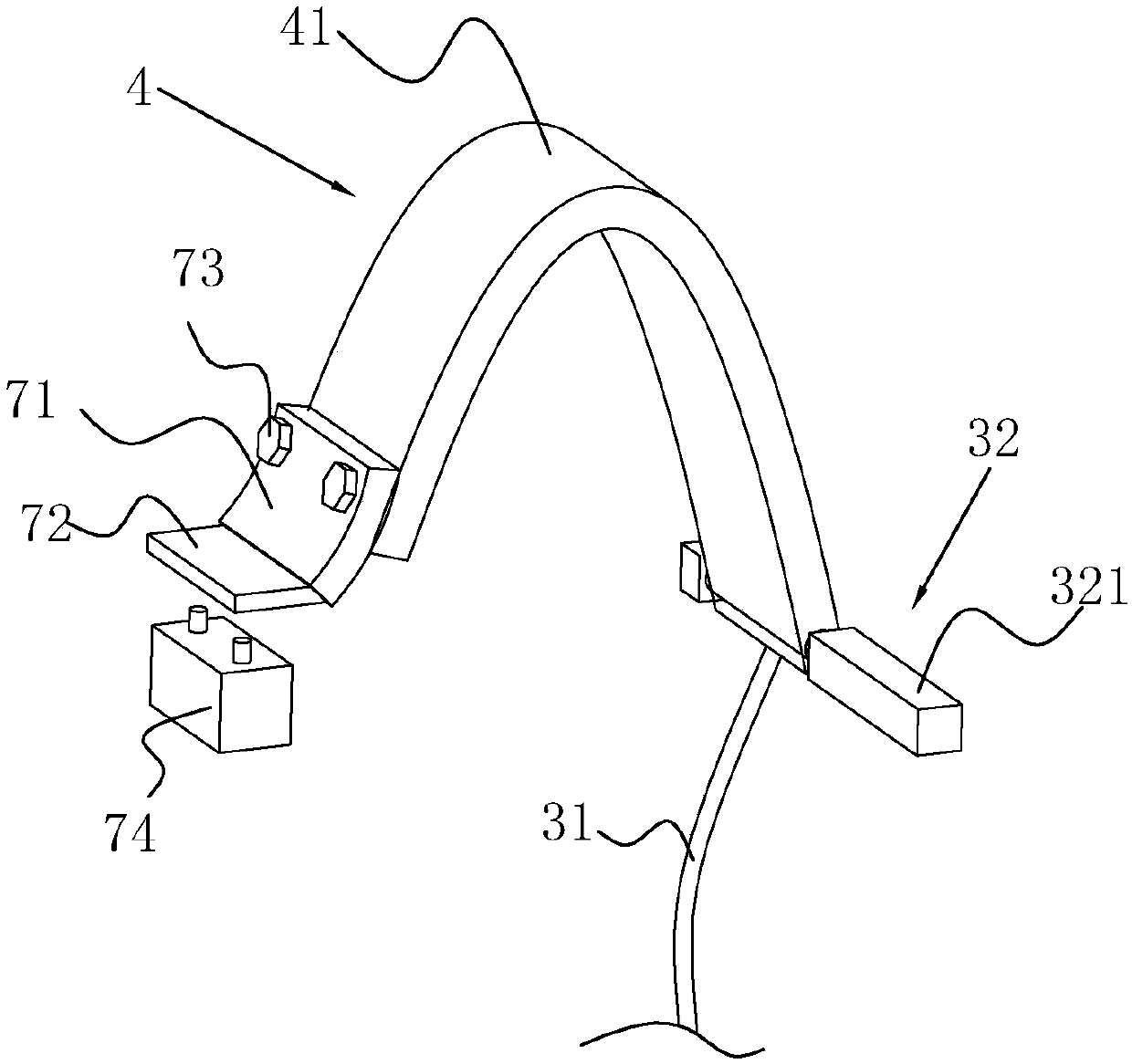

[0048] Embodiment 1, antistatic mechanism, such as figure 1 As shown, the frame 1 is included, the upper surface of the frame 1 is flat, and the frame 1 has two crossbars 11, two vertical drive assemblies 82 are fixed on the crossbar 11, and the vertical drive assembly 82 is equipped with a drive bar 22 moves up and down, and left and right two bar bars 22 are fixed with conductive wire mesh plate 21; Conductive wire mesh plate 21 is made of stainless steel wire, and bar bar 22 is also made of stainless steel, both conduct electricity mutually.

[0049] The vertical drive assembly 82 is a vertical cylinder, and the piston rod of the vertical cylinder is fixed to the bar 22, so by synchronously controlling the two vertical cylinders, the bar 22 and the conductive wire mesh plate 21 can be stably controlled to move up and down.

[0050] When printing, the load is spread flat on the upper surface of the frame 1, and the conductive screen plate 21 above the load is driven by the v...

Embodiment 2

[0060] Embodiment 2, screen printing machine, such as Figure 4 As shown, the anti-static mechanism described in Embodiment 1 is included, and a conveyor belt 81 is installed on the frame 1, and the conveyor belt 81 is placed between the upper surface of the frame 1 and the conductive wire mesh plate 21, and the receiving object passes through the conveyor belt. Below the screen plate 21 , the conductive screen presses down on the object, and then on the frame 1 , the scraper 83 scrapes the upper surface of the conductive screen plate 21 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com