An elevator counterweight device with associated counterweights and belts

A technology for heavy blocks and elevators, applied in transportation and packaging, lifting equipment in mines, etc., can solve problems such as slowing down the operation process, time-consuming, and hurting the handling personnel, so as to improve operation efficiency, speed up the maintenance process, The effect of strengthening the fastening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

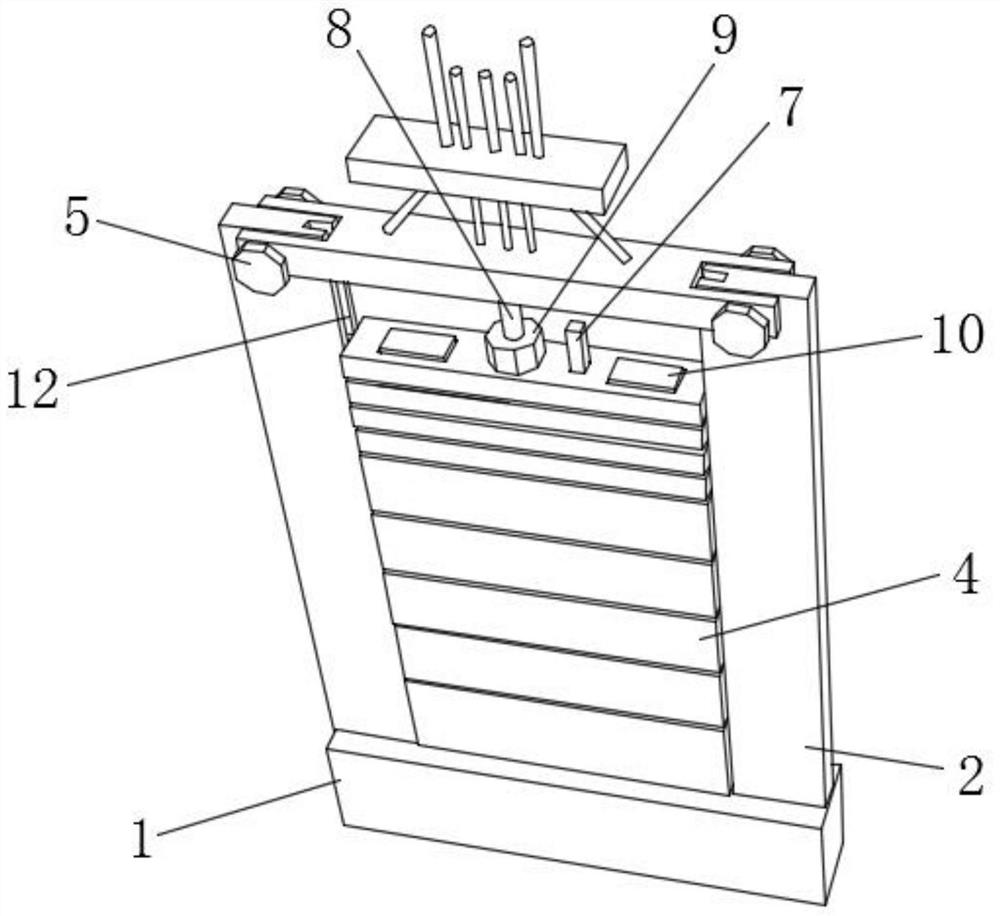

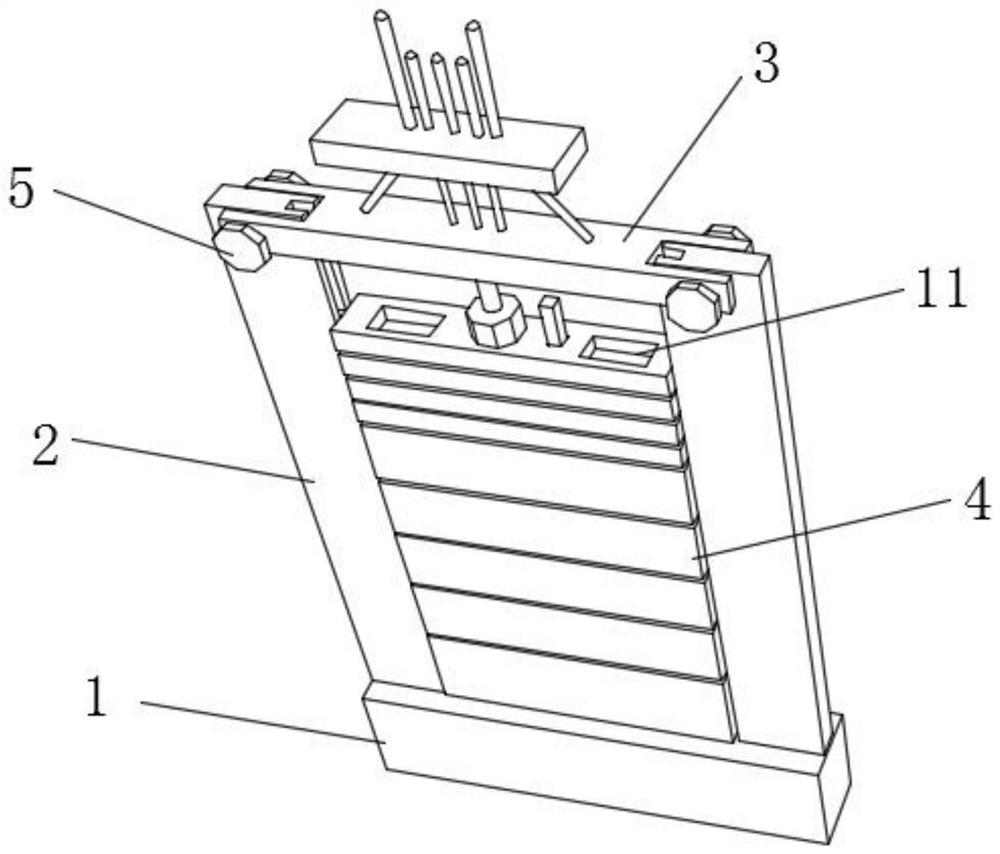

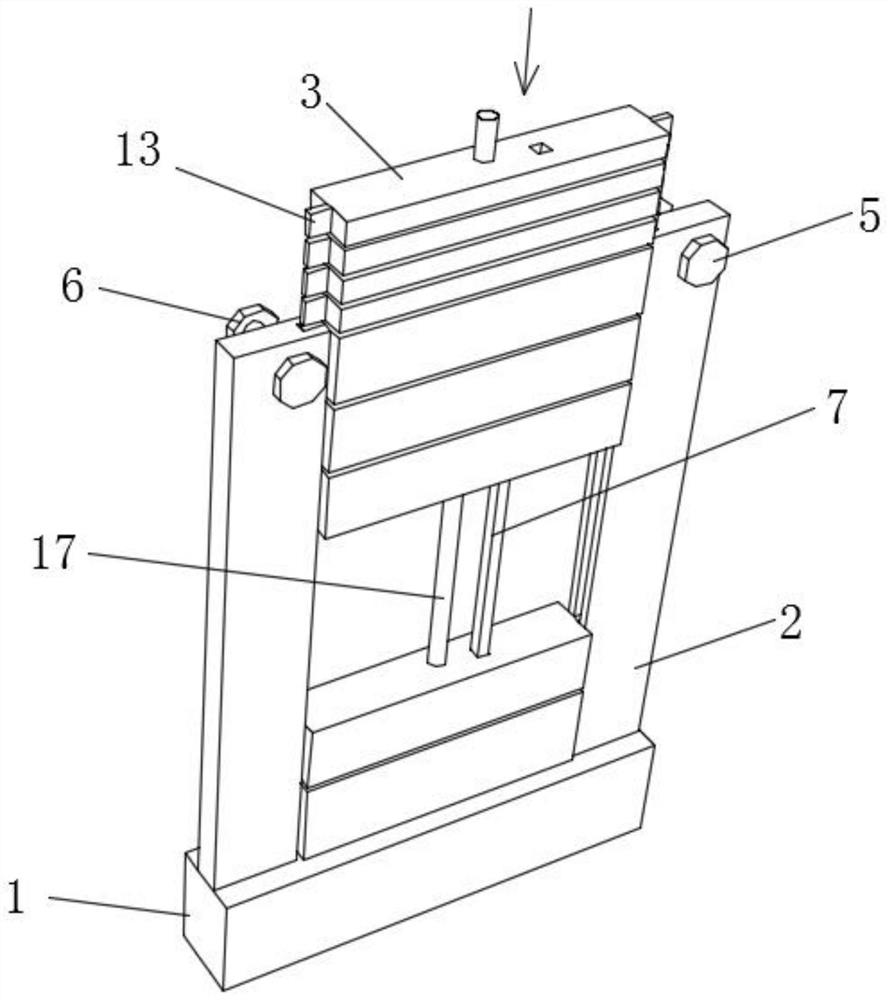

[0042] see figure 1 and figure 2 , a kind of elevator counterweight device with associated counterweights, including a counterweight frame and a counterweight block group, the counterweight block group is located inside the counterweight frame, and the counterweight frame includes a counterweight frame seat 1, a counterweight frame top 3 And a pair of counterweight frame sides 2, a pair of counterweight frame sides 2 are fixedly connected to the left and right ends of the upper side of the counterweight frame base 1, and the left and right ends of the counterweight frame top 3 are cut with openings, and the pair of openings are respectively connected to a pair of The upper end of the counterweight frame side 2 is matched, and the left and right ends of the counterweight frame top 3 and the upper end of the counterweight frame side 2 are correspondingly drilled with screw holes. The screw holes are threaded with fastening screws 5, and a pair of counterweight frame sides 2 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com