A method for improving the durability of a diamond composite sheet and a diamond composite sheet

A diamond composite sheet and diamond technology, applied in the field of methods and diamond composite sheets, can solve the problems of reducing the wear resistance of diamond, reducing the mechanical structure strength and service life of the diamond composite sheet, etc., so as to eliminate thermal stress concentration, eliminate interface effects, The effect of removing lattice defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

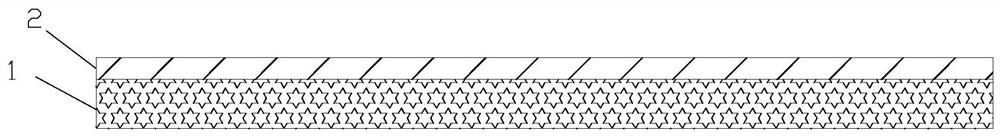

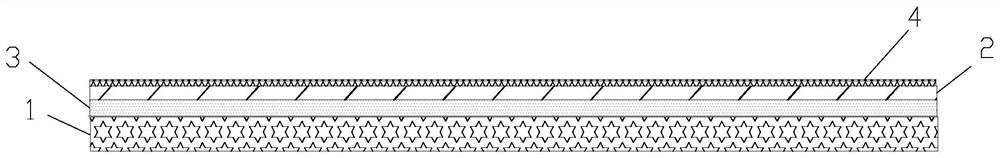

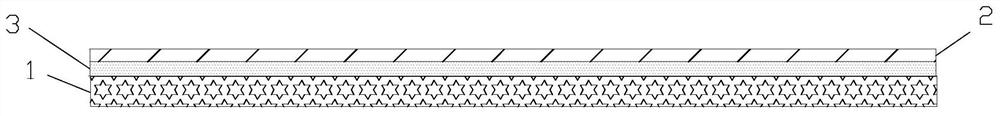

[0042] The method for improving the durable life of the diamond compact of the present embodiment comprises the following steps:

[0043] 1) Under the protection of an inert gas, an ultrafast pulsed laser beam is used to irradiate the interface between the substrate 1 and the diamond layer 2 and the surface of the diamond layer 2 to form a substrate at the interface between the substrate 1 and the diamond layer 2- The diamond gradient transition layer 3 forms a cobalt-rich layer 4 on the surface of the diamond layer, such as figure 2 shown; the irradiation time of the ultrafast pulsed laser beam is 1sec, and the irradiation area is 1×10 -4 mm 2 , with a frequency of 1×10 3 / sec, the pulse width of single pulse is 1×10 -13 sec, the energy density of a single pulse is 1mJ / mm 2, the total energy density of the ultrafast pulsed laser beam is 1J / mm 2 ;

[0044] 2) The cobalt-rich layer 4 on the surface of the diamond layer 2 is polished to remove the cobalt-rich layer 4 on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com