Sealing system for reducing leakage of lubricating oil of gas turbine

A technology of sealing system and lubricating oil, which is applied in the direction of engine lubrication, turbine/propulsion device lubrication, jet propulsion device, etc. It can solve the problems of lubricating oil leakage, deterioration, coking, etc., and achieve the effect of reducing lubricating oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

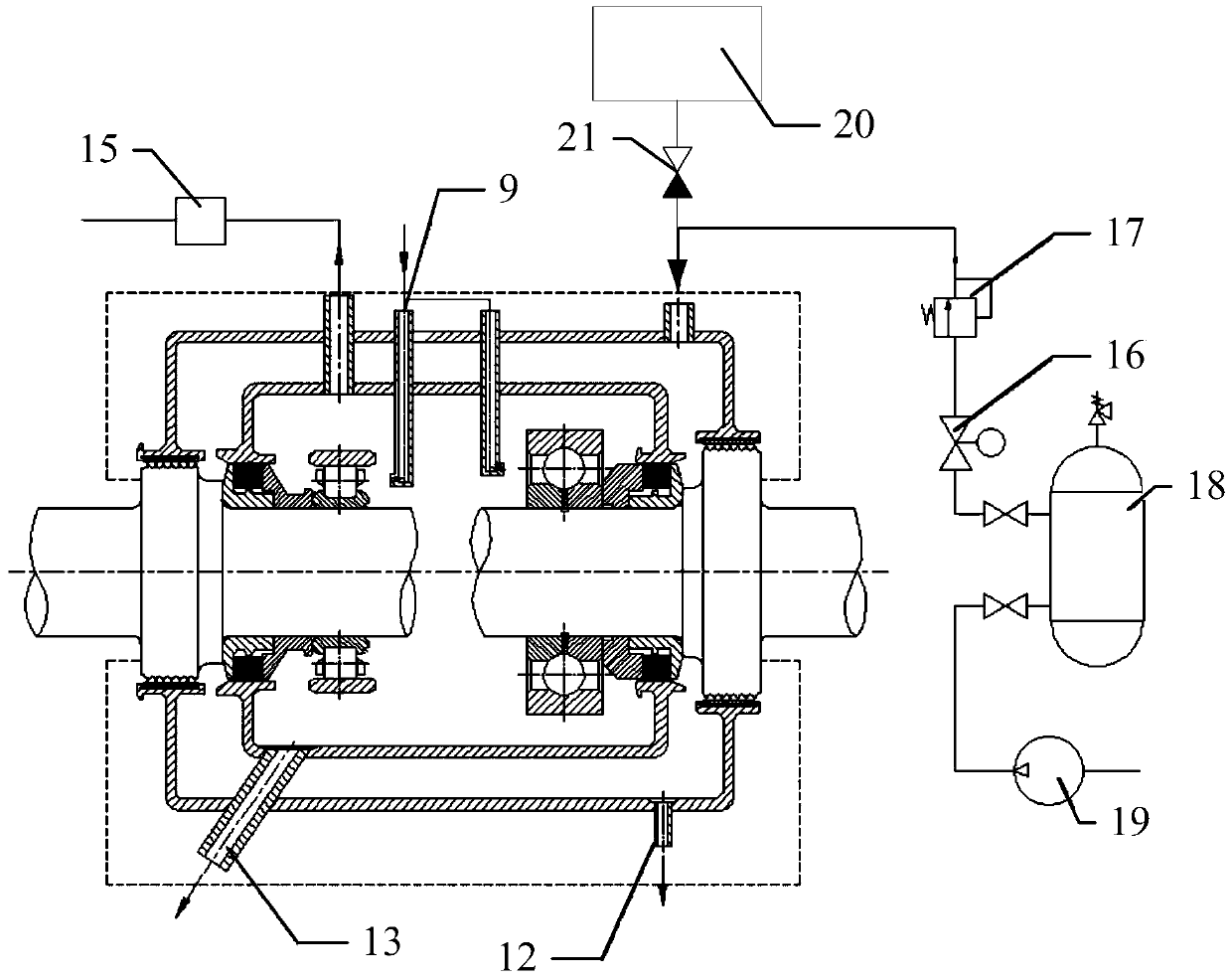

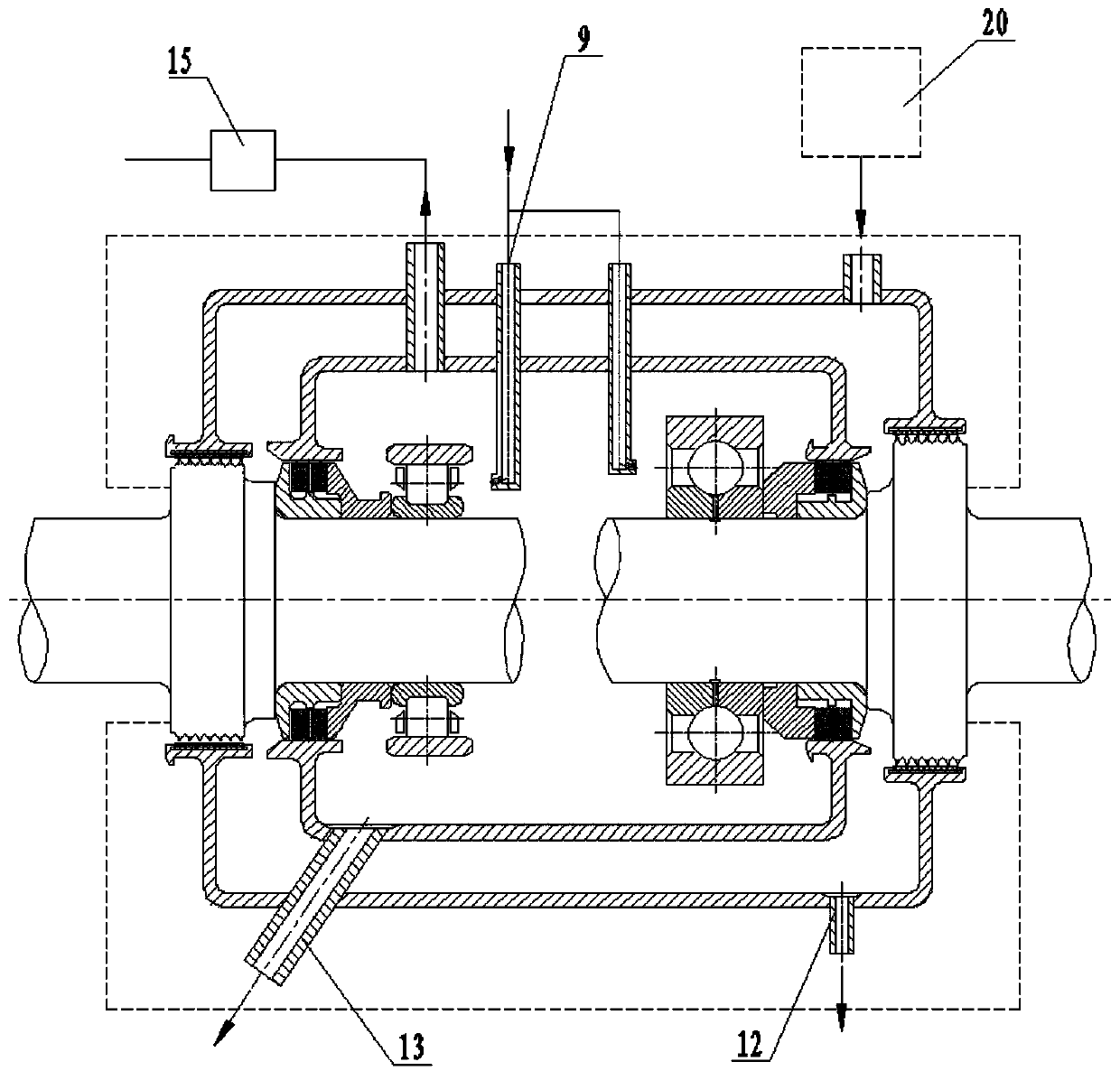

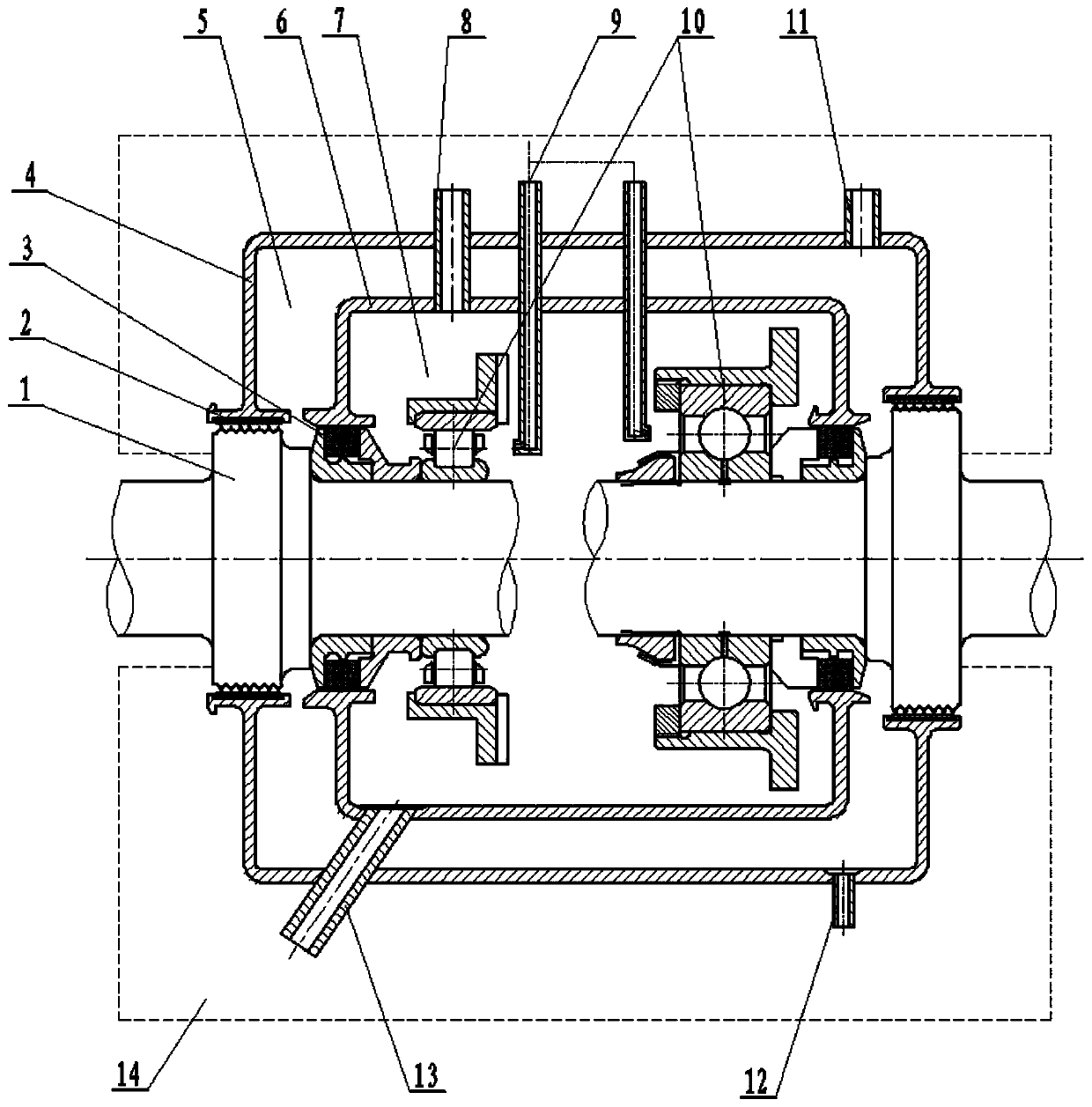

[0028] Specific implementation mode one, the following combination Figure 1-3 Describe this embodiment. This embodiment provides a sealing system that reduces lubricating oil leakage. The structural schematic diagram of the sealing system applied to a gas turbine is as follows figure 1 shown; including the body of the lubricating oil sealing device, the sealing system also includes a pressurized bleed air system 20,

[0029] The air outlet end of the pressurized bleed air system 20 communicates with the sealed air cavity 5 of the lubricating oil sealing device body through the air supply pipe 11 of the sealed air cavity of the lubricating oil sealing device body, and a one-way valve 21,

[0030] Also includes air pressurization system,

[0031] The air outlet end of the air booster system communicates with the sealed air cavity 5 of the lubricating oil sealing device body through the air supply pipe 11 of the sealed air cavity of the lubricating oil sealing device body;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com