Optical module and optoelectronic demodulation module for fluorescence optical fiber temperature-control system

An optical module and temperature control system technology, applied in the coupling of optics, optical components, optical waveguides, etc., can solve problems such as affecting the efficiency and accuracy of fluorescent fiber temperature measurement, impurity blocking the optical path transmission of the module, and optical signals failing to transmit normally. Achieve the effect of improving temperature measurement efficiency and temperature measurement accuracy, improving reliability and stability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0039] The present invention will be further described in detail below with reference to the drawings and embodiments.

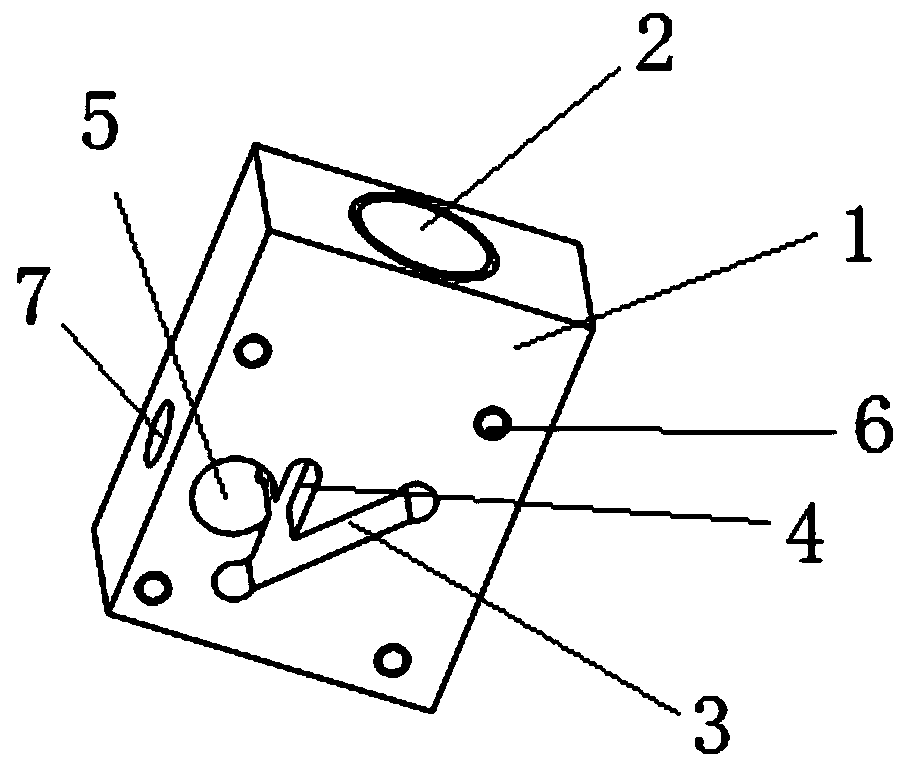

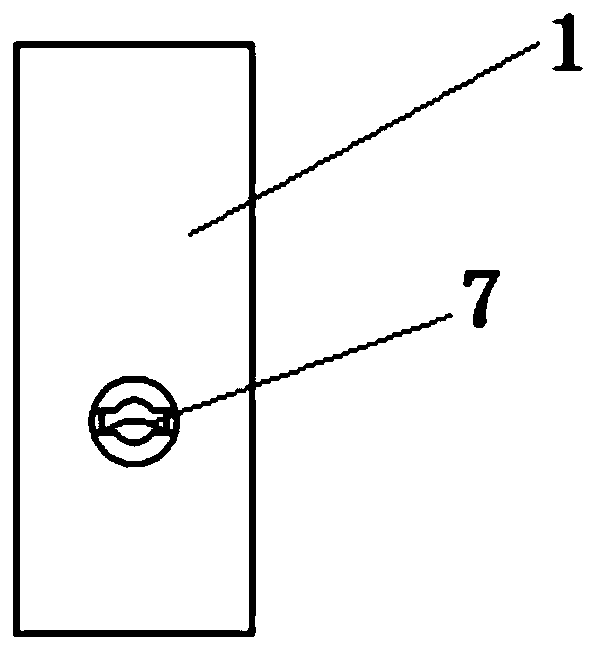

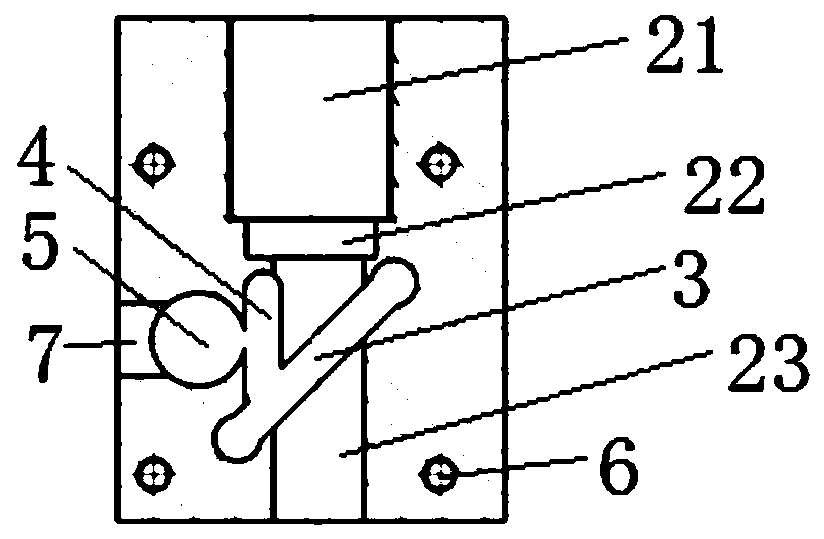

[0040] Such as Figure 1 to 5 As shown, an optical module for a fluorescent optical fiber temperature control system includes a mounting base 1 and a light emitting diode 81, a lens 82, an optical fiber connector 83, a first filter 84, and a second filter 85 arranged in the mounting base. The material of the mounting seat is aluminum alloy; the front surface of the mounting seat is provided with three stepped through holes 2 penetrating through the rear surface, which are respectively the first through hole 21, the second through hole 22 and the third through hole 23 with decreasing diameters. , The first through hole 21 is provided with a thread; one end of the optical fiber connector 83 is installed in the first through hole 21, one end of the lens 82 is installed in the second through hole 22, and the light emitting diode 81 is installed in the third through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com