A ladder-type probe element for measuring the attitude of flyers driven by detonation and its testing method

A bracket type and component technology, applied in the field of step bracket type probe components, can solve the problems of large human error of negative film, difficult to accurately determine wave head position, harsh test conditions, etc., to improve reliability, save pre-experiment preparation, The effect of reducing the difficulty of operation and the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

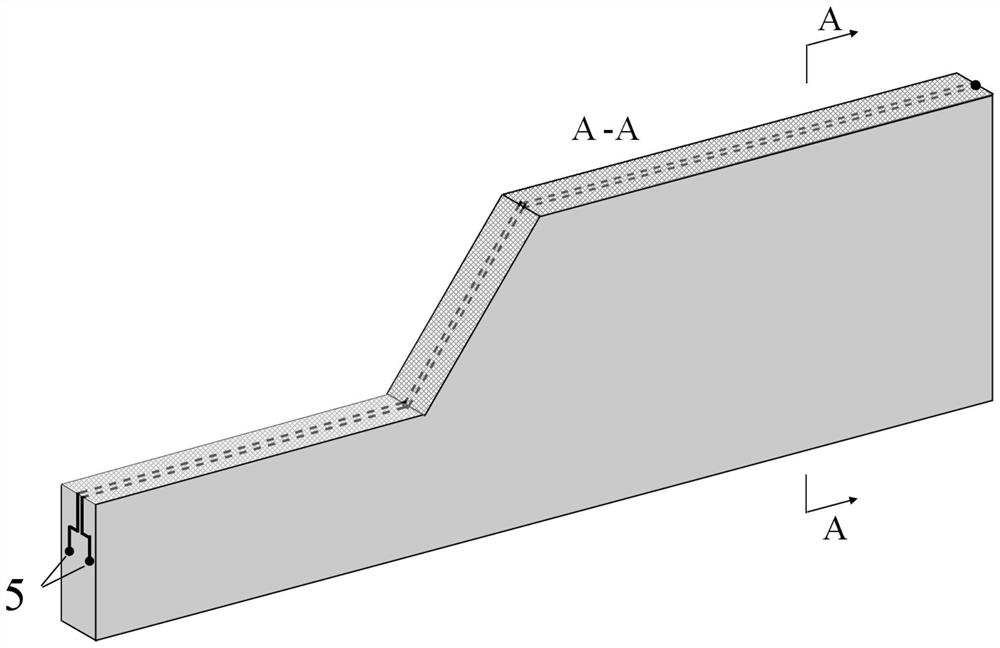

[0030] Embodiment 1 makes ladder support type probe element

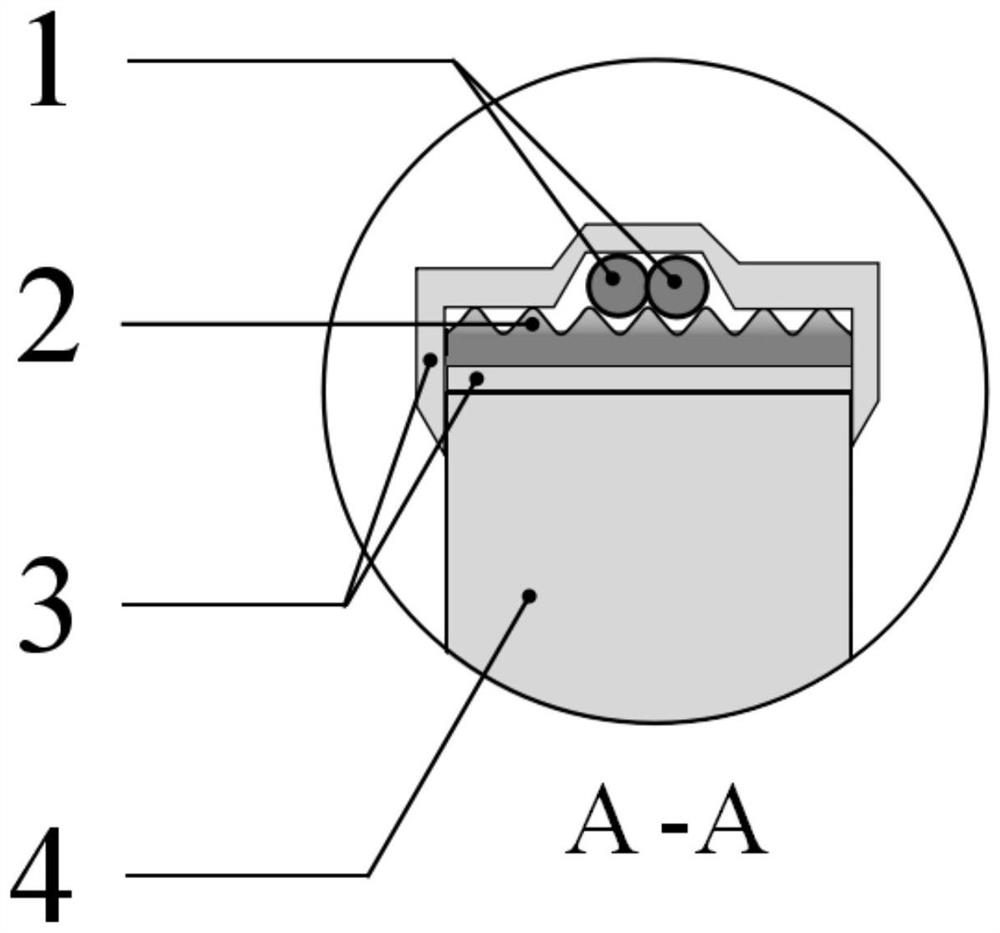

[0031] To make a stepped bracket type probe element: first cut a 6mm thick plexiglass sheet into a ladder shape as shown in Figure 1, where the upper step is 100-200mm long and 20-100mm high, and the lower step is 0-200mm long and high 0~20mm, the inclination angle of the inclined surface is 45°; a layer of copper foil and stainless steel wire mesh are pasted and laid successively on the plexiglass step surface, in which the stainless steel wire mesh is 60 mesh, the wire diameter is 0.12mm, and the aperture is 0.25mm; the diameter 0.08mm, the thickness of the enamelled layer is about 0.016mm, and the enamelled resistance wire with a unit length resistance value of 279Ω / m is folded in half and twisted into a strand, then laid along the axial direction of the stainless steel wire mesh, and covered with copper foil for shielding, and the internal air is squeezed out when used , the two ends of the enamelled resistance ...

Embodiment 2

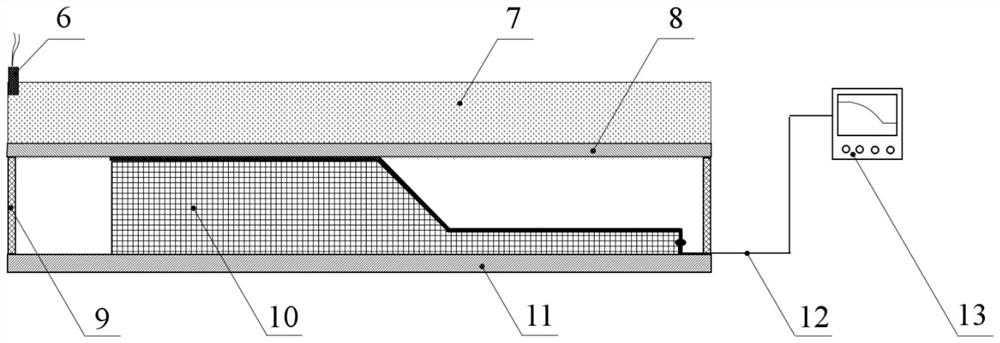

[0032] Embodiment 2 Utilizes the probe element of embodiment 1 to carry out flat-panel flight attitude measurement test

[0033] The specific dimensions of the stepped bracket type probe element are: the length of the upper step is 100mm, the height is 25mm, the length of the lower step is 200mm, the height is 5mm, and the inclination angle of the inclined surface is 45°; the experimental device is according to figure 2Design, the double board and the base plate are made of cold-rolled steel plate, 800mm long, 200mm wide, and 2mm thick. First, place the base plate on a flat sandy ground, and use superglue to fix the ladder-type probe element on the center of the upper surface of the base plate. The head of the element (the side of the upper step surface) is 300mm away from the initiation end, connect one end of the coaxial cable to the output end of the probe element, and use aluminum foil to paste the shield; And use a thin aluminum sheet with a height of 25mm to support the ...

Embodiment 3

[0034] Embodiment 3 utilizes the probe element of embodiment 1 to carry out circular tube flight attitude measurement test

[0035] The specific dimensions of the stepped bracket type probe element are: the length of the upper step is 100mm, the height is 45mm, the length of the lower step is 5mm, the height is 5mm, and the inclination angle of the inclined surface is 45°; the experimental device is according to image 3 Design, the copper tube material is red copper, the outer diameter is 30.4mm, the thickness is 2.5mm, and the length is 300mm. The inside is evenly filled with a certain density of powdery RDX. Use super glue to fix the ladder bracket type probe element on the wooden frame, and then fix it It is clamped and fixed with the copper pipe as a whole, and installed on the base; the height of the frame is 250mm, that is, the head of the probe element (the side of the upper step surface) is 50mm away from the initiation end, and one end of the coaxial cable is connecte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com