Detection device for measuring flatness and spherical degree of bridge support

A technology of bridge bearings and detection devices, which is applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, can solve the problems of affecting test efficiency and lack of testing tools, and achieve accurate measurement results, no safety hazards, and fast results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

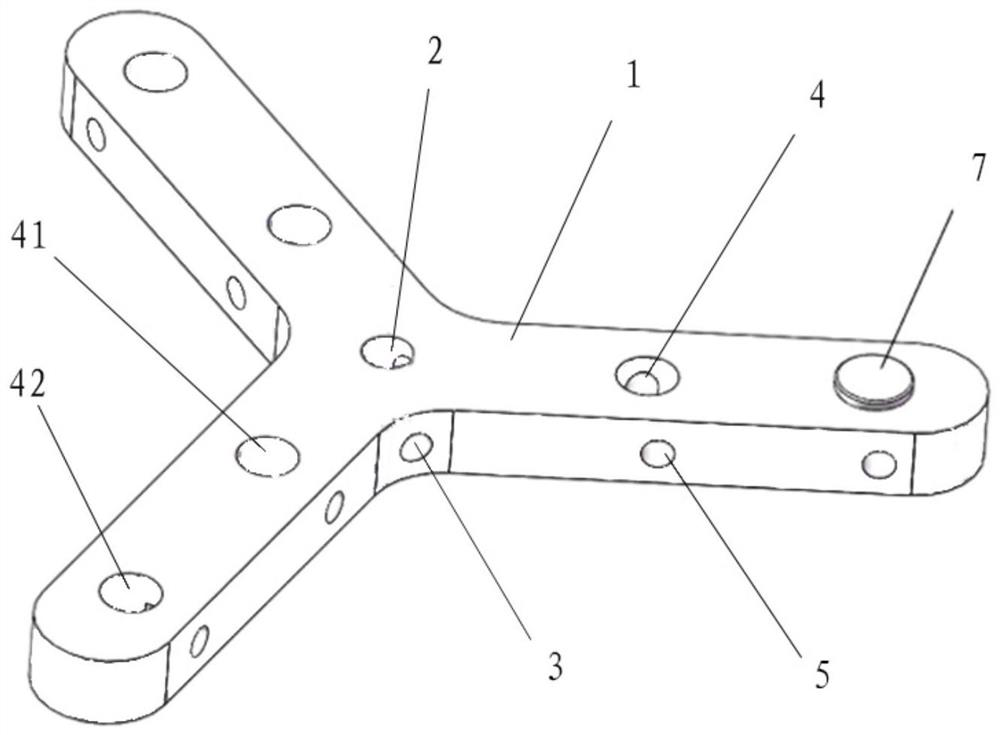

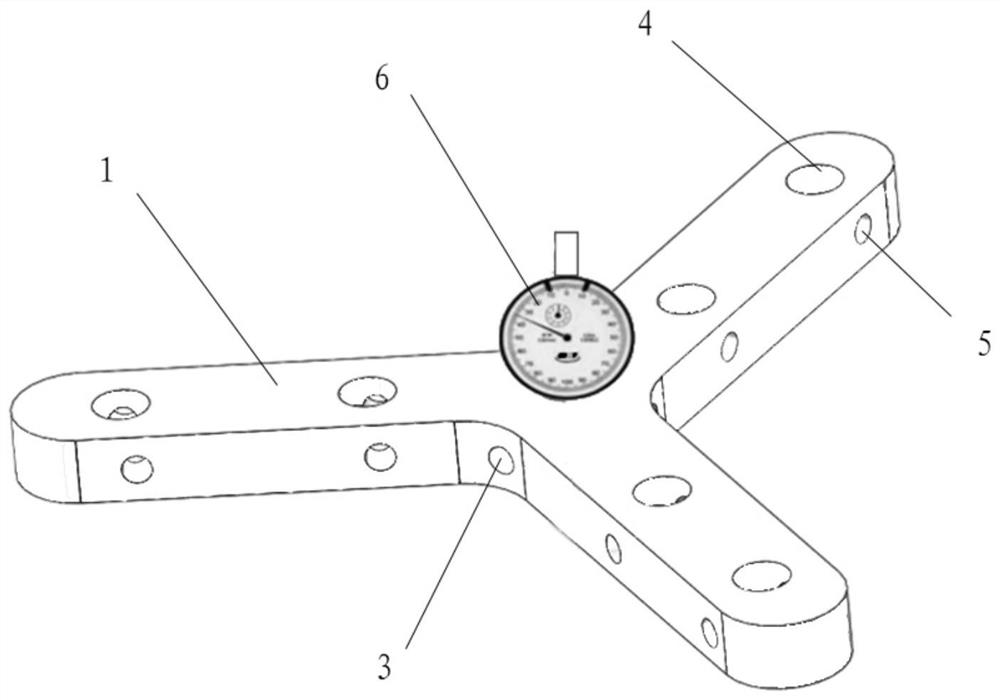

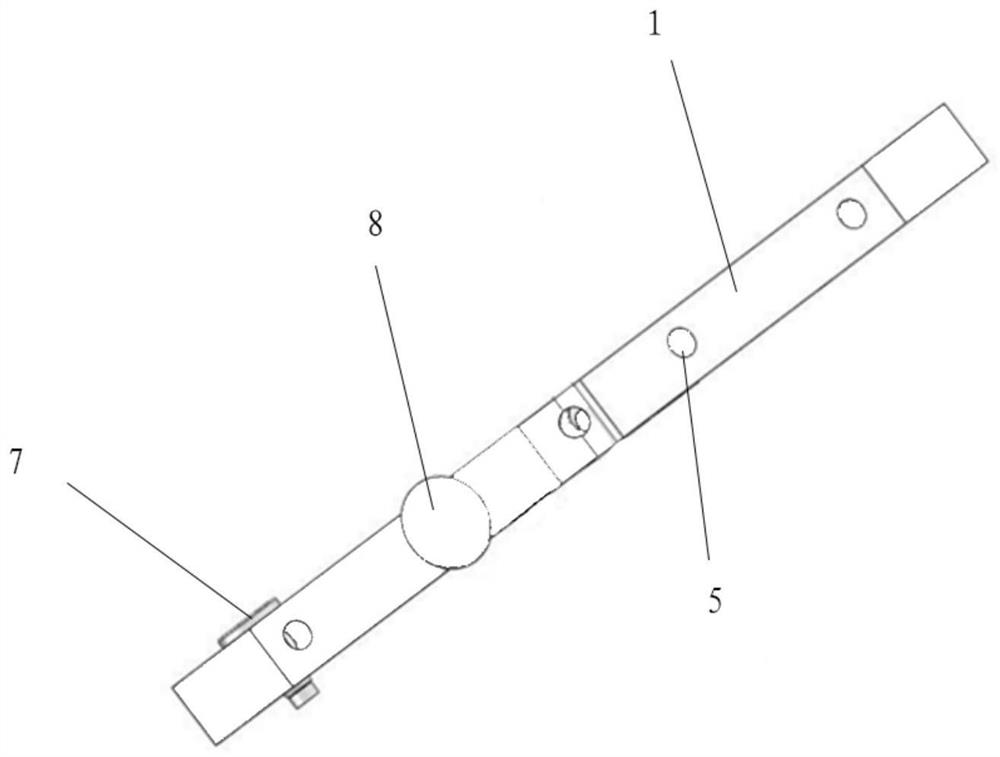

[0022] see Figure 1 to Figure 3 , the present invention provides a detection device for measuring the flatness and sphericity of a bridge support, comprising a Y-shaped fork 1, a dial gauge 6, a positioning pin 7, a first locking pin (not shown) and a second Locking pin 8.

[0023] The Y-shaped fork 1 is a three-sided component in a Y-shape, and the three sides of the Y-shaped fork 1 are 120° to each other, and the lengths of the three sides are equal.

[0024] Preferably, the top and side walls of the three sides of the Y-shaped fork 1 are rounded to prevent bumps and scratches during use.

[0025] At the center of the Y-shaped fork 1, there is a dial gauge installation hole 2 vertically through, for inserting the dial gauge 6 therein for detection. On the side wall of the junction of any two sides of the Y-shaped fork 1, a horizontal dial gauge locking hole 3 is provided. After the dial gauge 6 is inserted into the dial gauge mounting hole 2, use the first locking pin (in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com