Tire contour measurement method based on camera shooting

A profile measurement and tire technology, applied in the field of graphic processing measurement, can solve the problems of lack of real-time detection methods, hidden dangers of driving safety, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

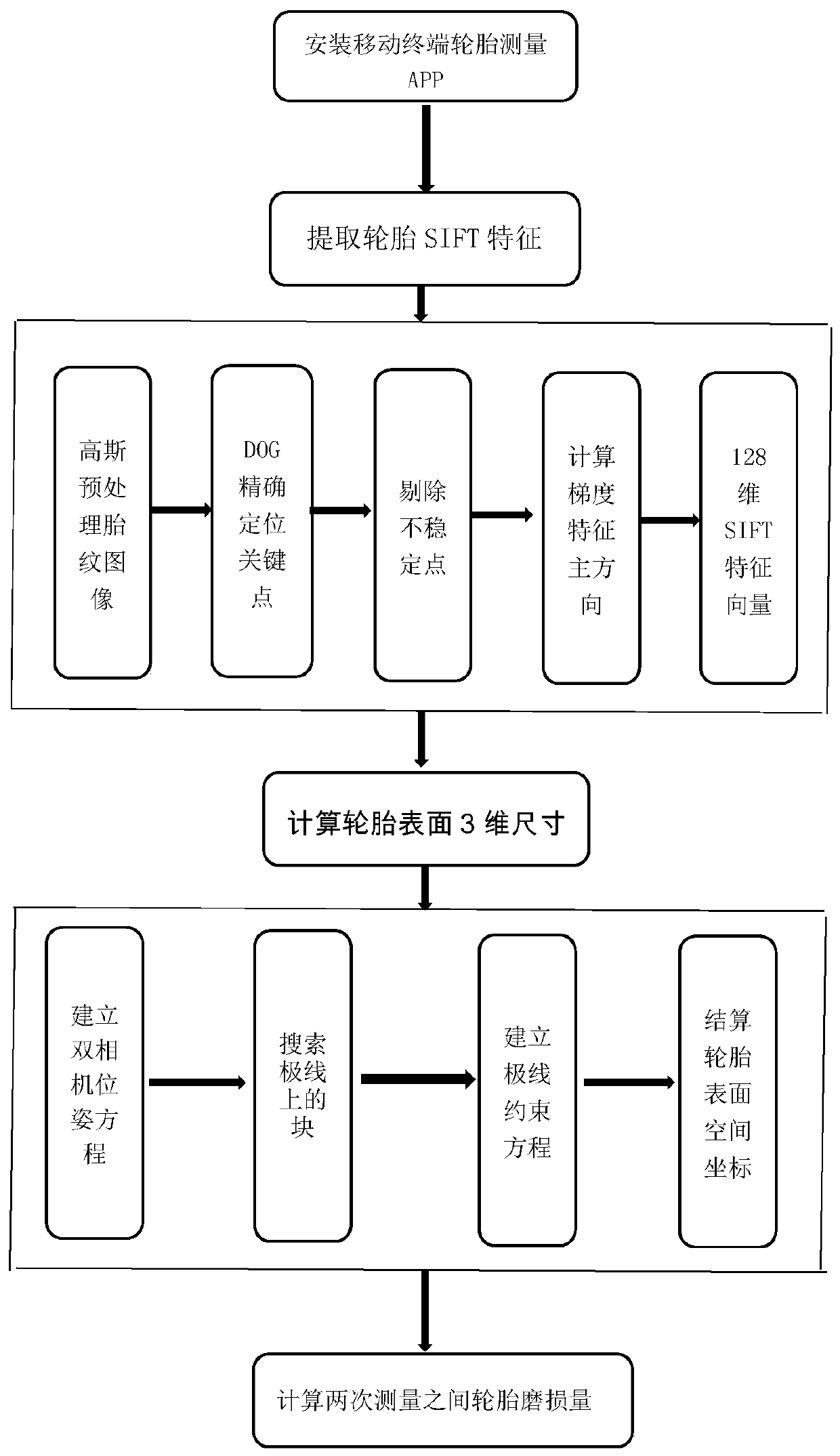

[0083] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

[0084] Those skilled in the art can understand that, unless otherwise defined, all terms (including technical terms and scientific terms) used herein have the same meaning as commonly understood by one of ordinary skill in the art to which this invention belongs.

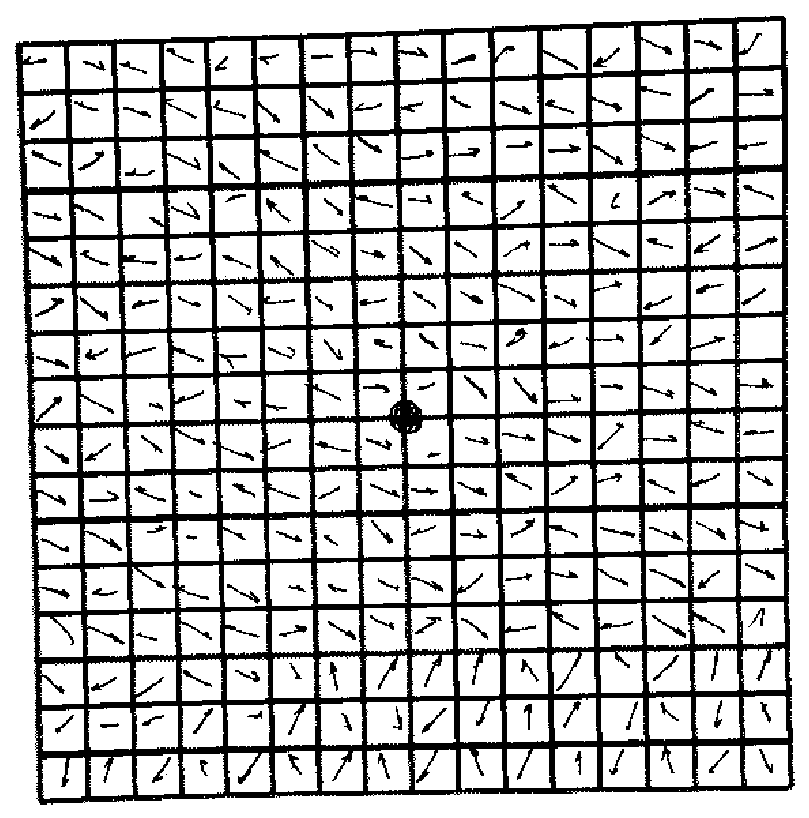

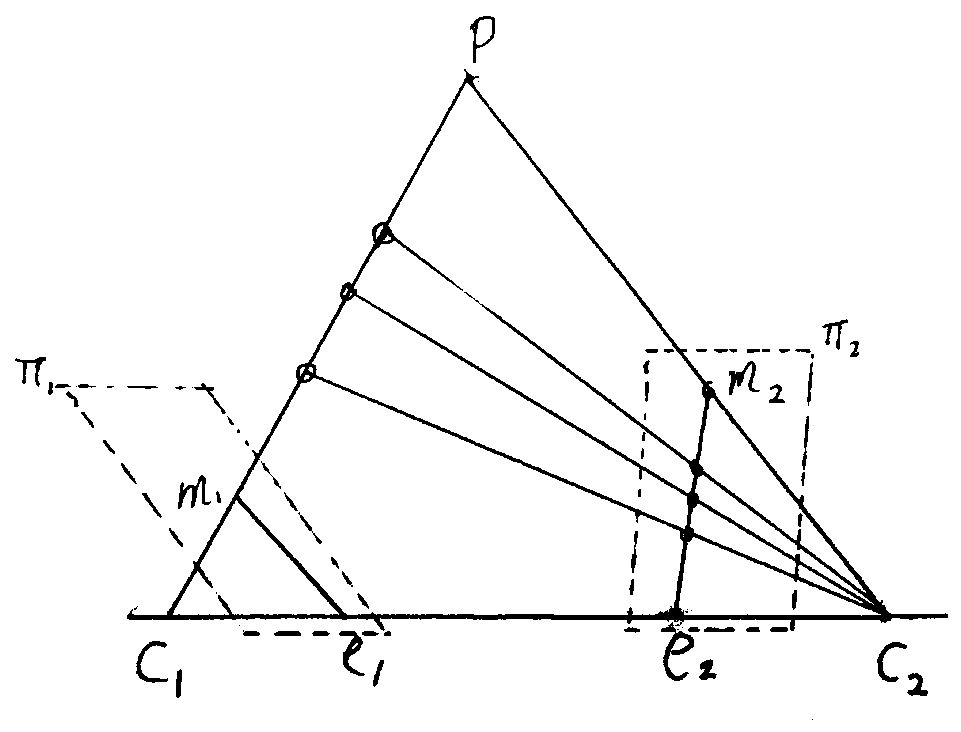

[0085] The present invention extracts the sparse image of the tread outline and key point feature values from a single two-dimensional image by using the same tire tread image taken at different positions by the camera of the mobile terminal, and establishes the image pixel gray value according to the tire tread The key point feature matrix of the rate of change and direction of change is used to calculate the feature values of multiple identical key points in two or more sparse tread pattern images. By comparing the calculated camera internal parameters and the three-dimensional spac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com