Method for preparing acrylonitrile-based polymer for manufacture of carbon fiber

A technology of acrylonitrile and carbon fiber, which is applied in the chemical characteristics of fibers, textiles and papermaking, etc., can solve the problems of high viscosity of polymer solution, reduced weight average molecular weight, and low efficiency, and achieves low polydispersity index and high final polymerization conversion. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

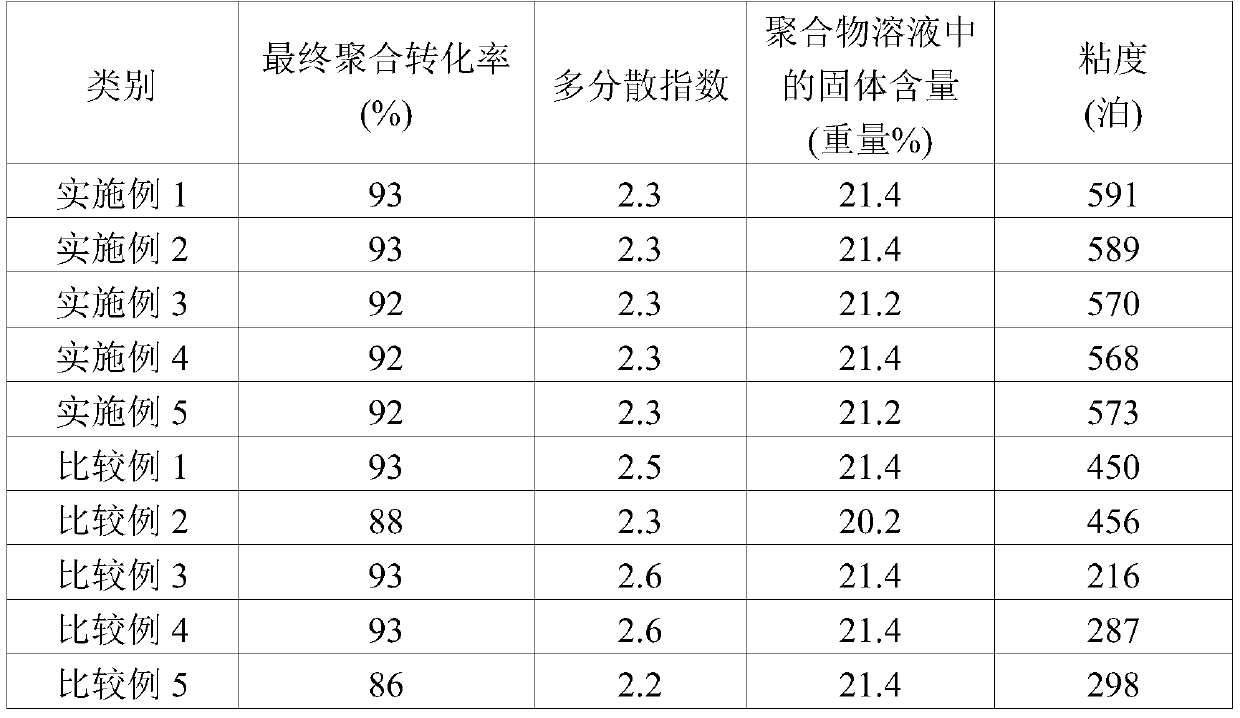

Examples

preparation example Construction

[0019] A method for producing an acrylonitrile-based polymer for producing carbon fibers according to an exemplary embodiment of the present invention includes: (1) preparing a reaction solution comprising a (meth)acrylonitrile-based monomer and a first reaction solvent, (2 ) adding an initiator to the reaction solution for the first time to initiate polymerization, and (3) adding the initiator for a second time to perform polymerization at a time point when the polymer conversion rate reaches 70% to 80%.

[0020] Hereinafter, each step of the preparation method according to the present invention will be described in detail.

[0021] (1) Preparation of reaction solution

[0022] First, a reaction solution containing a (meth)acrylonitrile-based monomer and a first reaction solvent is prepared.

[0023] The (meth)acrylonitrile-based monomer may be one or more selected from acrylonitrile and methacrylonitrile, and is preferably acrylonitrile.

[0024] The first reaction solvent...

Embodiment 1

[0054] A reaction solution was prepared by uniformly dissolving 100 parts by weight of a monomer mixture in which acrylonitrile, methyl acrylate, and itaconic acid were mixed in a molar ratio of 97:2:1 in 365 parts by weight of dimethylsulfoxide. A radical polymerization initiator solution was prepared by uniformly dissolving 0.2 parts by weight of azobisisobutyronitrile as a radical polymerization initiator in 5 parts by weight of dimethylsulfoxide.

[0055] The reaction solution was added to a reactor equipped with a stirrer, nitrogen replacement was performed, and then the temperature in the reactor was raised to 70°C. Add 0.4 parts by weight of azobisisobutyronitrile as a radical polymerization initiator to carry out solution polymerization for 5 hours, add the radical polymerization initiator solution of the whole amount in batches (at the point in time when the polymerization conversion rate reaches 70%) to After performing the polymerization reaction for 8 hours, the re...

Embodiment 2

[0057] Acrylonitrile was obtained by the same method as described in Example 1, except that the entire amount of the radical polymerization initiator solution was added in portions after the solution polymerization was carried out for 6 hours (at the time point when the polymerization conversion ratio reached 75%) Polymer solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com