High-strength copolymerized aramid fiber and its preparation method

一种芳族聚酰胺、高强度的技术,应用在单组分共聚多酰胺人造长丝、纤维处理、纺丝溶液制备等方向,能够解决纺丝液生产率降低、聚合物链长度降低、共聚芳族聚酰胺纤维强度和弹性模量劣化等问题,达到优异溶解性、优异可纺性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

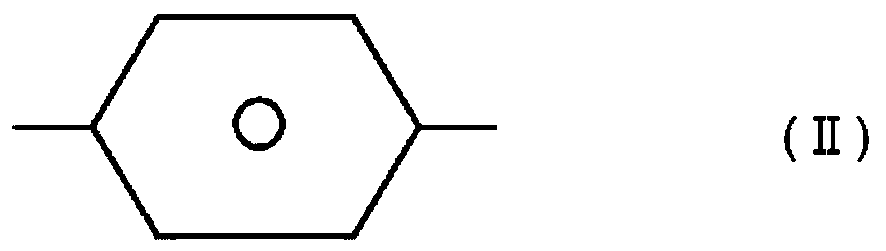

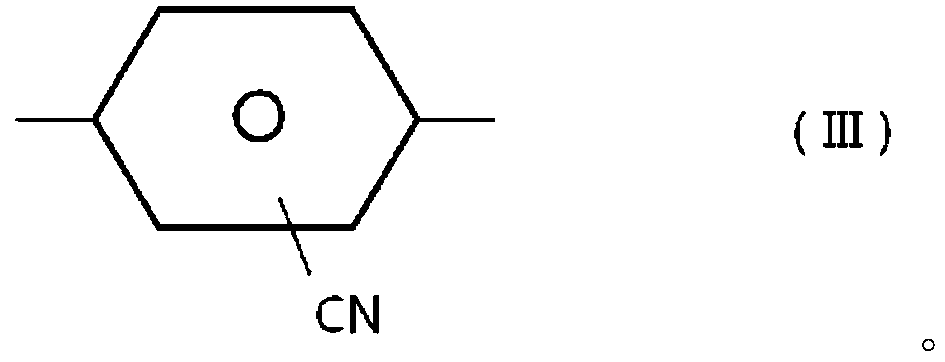

[0025] According to one aspect of the present invention, there is provided a method for preparing high-strength copolymerized aramid fibers, comprising: (i) adding a neutralizing agent to an organic solvent and then dispersing it; (ii) making the molar ratio 1: 9 to 9:1 p-phenylenediamine and cyano-p-phenylenediamine are dissolved in the above-mentioned organic solvent dispersed with a neutralizing agent; Terephthaloyl chloride in an equal molar amount is added to the above-mentioned organic solvent dispersed with a neutralizing agent and dissolved with p-phenylenediamine and cyano-p-phenylenediamine, and then reacting them to prepare a spinning solution; and (iv) Spinning the spinning solution to prepare copolymerized aramid fibers.

[0026] According to another aspect of the present invention, there is provided a method for preparing high-strength copolymerized aramid fibers, comprising: (i) p-phenylenediamine and cyano-p-phenylene with a molar ratio of 1:9 to 9:1 Diamine i...

Embodiment 1

[0046] Under a nitrogen atmosphere, 30 g of N-methyl-2-pyrrolidone (organic solvent) containing 3% by weight of calcium chloride (inorganic salt) was added to the reactor, and 6.99 g of calcium oxide (in and agent) and disperse it.

[0047] Then, 5.7 g of p-phenylenediamine and 10.55 g of cyano-p-phenylenediamine were added to the organic solvent in which the neutralizing agent was dispersed, followed by dissolving them in the reactor to prepare a mixed solution.

[0048] Next, 26.79 g of terephthaloyl chloride was added to the mixed solution in which the neutralizing agent was dispersed and p-phenylenediamine and cyano-p-phenylenediamine were dissolved, and then the solution was reacted, thereby preparing Spinning solution of family polyamide copolymer.

[0049] As a result of visually observing the prepared spinning dope, no gel or solid phase was found, and therefore, it can be seen that the aramid copolymer in the spinning dope has excellent solubility.

[0050] Then, af...

Embodiment 2

[0054] Under a nitrogen atmosphere, 30 g of N-methyl-2-pyrrolidone (organic solvent) containing 3% by weight of calcium chloride (inorganic salt) was added to the reactor, and 6.99 g of calcium oxide (in and agent) and disperse it.

[0055] Then, 5.7 g of p-phenylenediamine and 10.55 g of cyano-p-phenylenediamine were added to the organic solvent in which the neutralizing agent was dispersed, followed by dissolving them in the reactor to prepare a mixed solution.

[0056] Next, 26.79 g of terephthaloyl chloride was added to the mixed solution in which the neutralizing agent was dispersed and p-phenylenediamine and cyano-p-phenylenediamine were dissolved, and then the solution was reacted at -90° C., thereby preparing A spinning solution in which an aramid copolymer is uniformly dissolved.

[0057] As a result of visually observing the prepared spinning dope, no gel or solid phase was found, and therefore, it can be seen that the aramid copolymer in the spinning dope has excel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| composition ratio | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

| polydispersity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com