Unmanned flying robot based on compressed air cold assistance launching

A technology for flying robots and compressed gas, applied in the field of flying robots and unmanned aerial robots, can solve the problems of slow flight speed, increasing the time to reach the mission area, being shot down by the opponent, damaged, and the effective flight time of the aircraft cannot be well utilized. , to achieve the effect of increasing the blanking time and improving the survival rate of the battlefield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

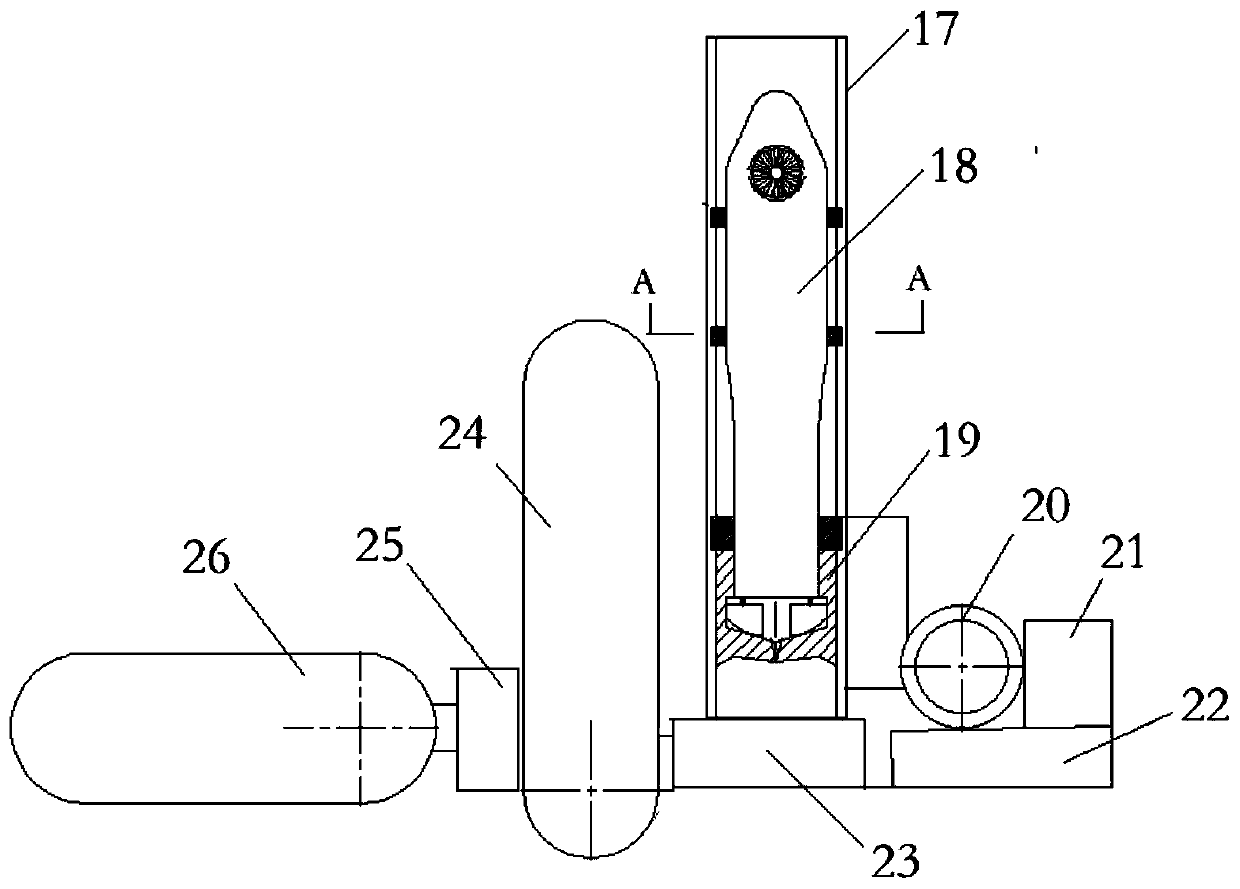

[0025] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0026] The present invention provides a kind of unmanned aerial robot based on compressed gas cold-assisted launch, unmanned aerial robot 17 utilizes the compressed air of compressed gas cold-assisted launching mechanism compressed air as auxiliary power to carry out ejection and take-off, and unmanned aerial robot 17 takes off with its own The main thrust of the turbojet realizes the horizontal flight of the unmanned flying robot 17, and the flight direction change and vertical lift of the unmanned flying robot 17 are realized with the auxiliary electric drive as the auxiliary power.

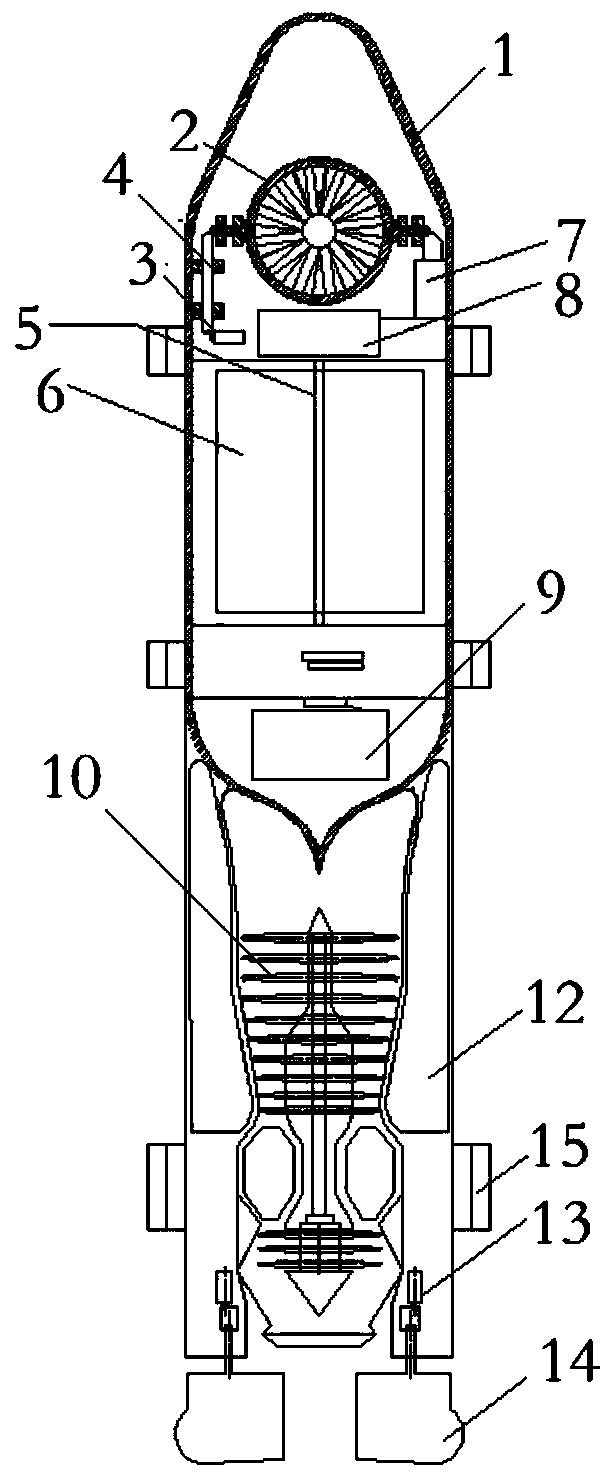

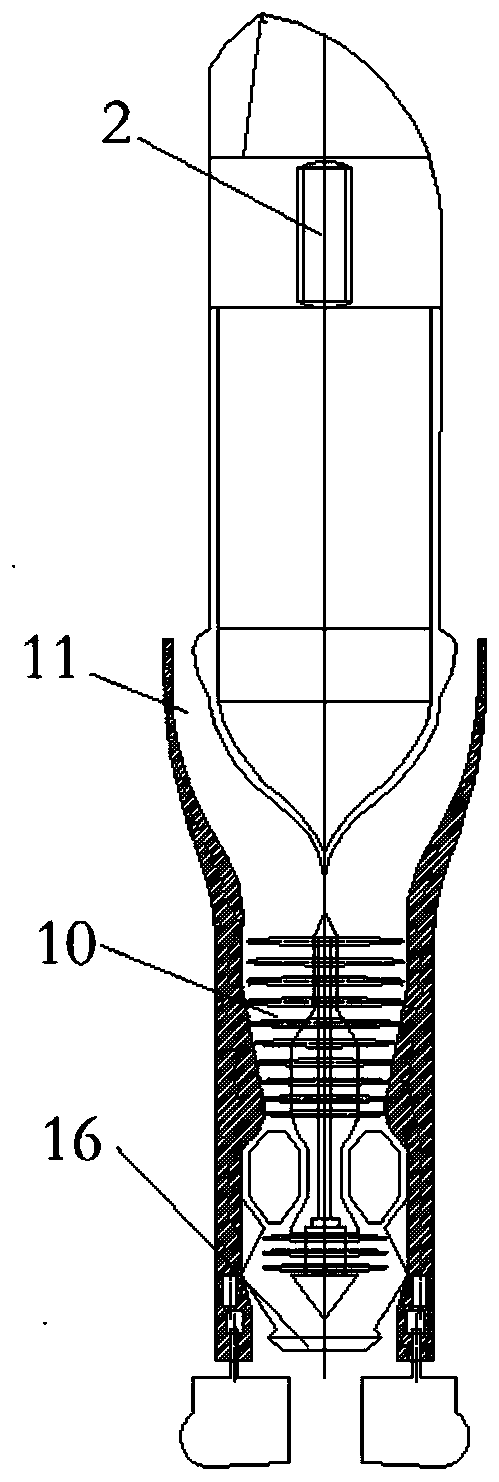

[0027] as attached figure 1 and 2 As shown, the unmanned aerial robot 17 includes a robot housing 1, an auxiliary electric turbofan 2, a swing motor 3, a transmission mechanism 4, a frame-type mission cabin 5, a mission load 6, a gyroscope 7, a control module 8, a power ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com