Recovery technology and system of PTA in alkali decrement wastewater

A technology of alkali reduction wastewater and recovery system, which is applied in textile industry wastewater treatment, water pollutants, multi-stage water treatment, etc., can solve the problems of low utilization value, waste of resources, waste cost of alkali resources, etc., and achieve improved recycling Effects of utilization rate, COD reduction and sewage discharge reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

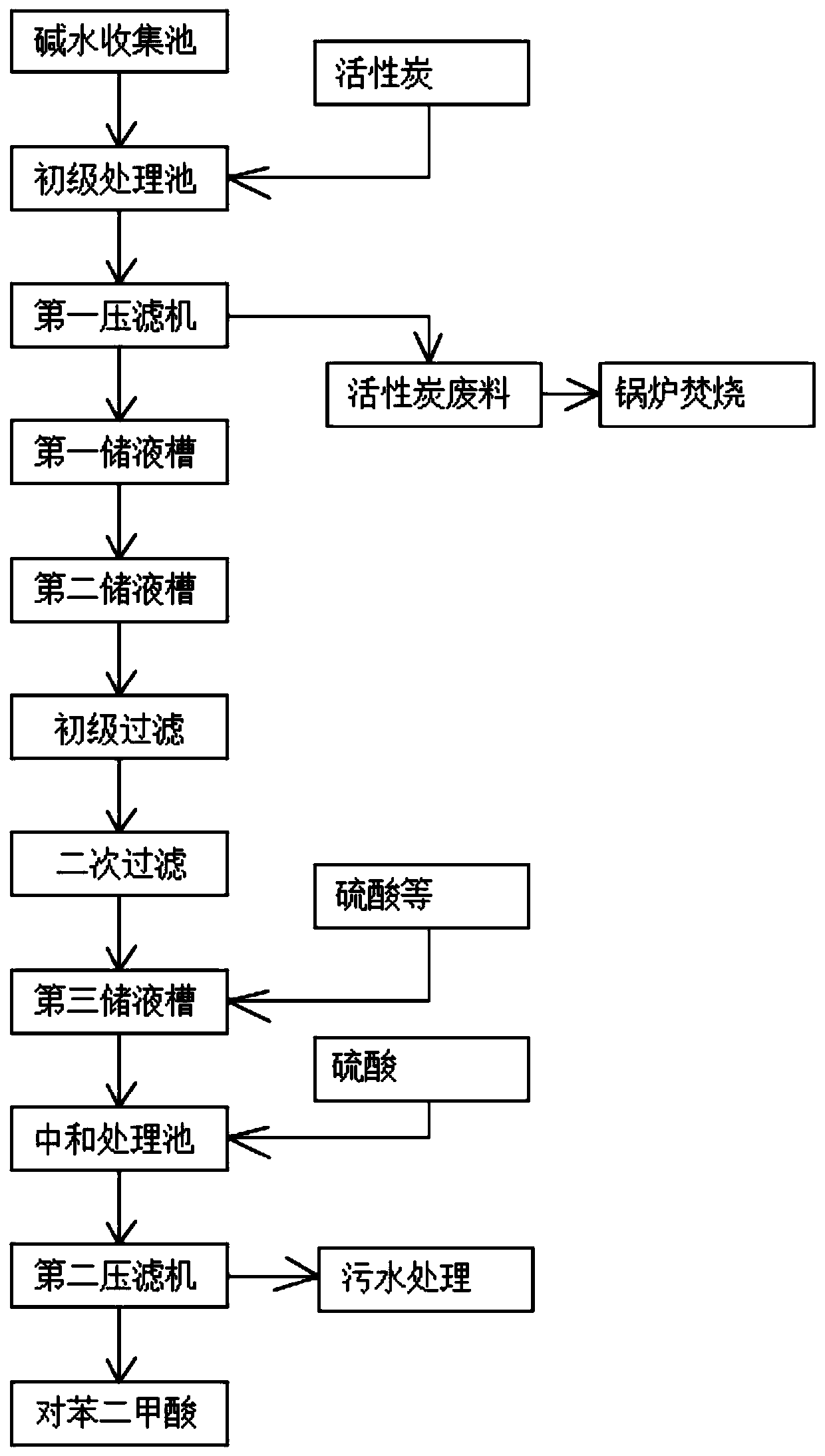

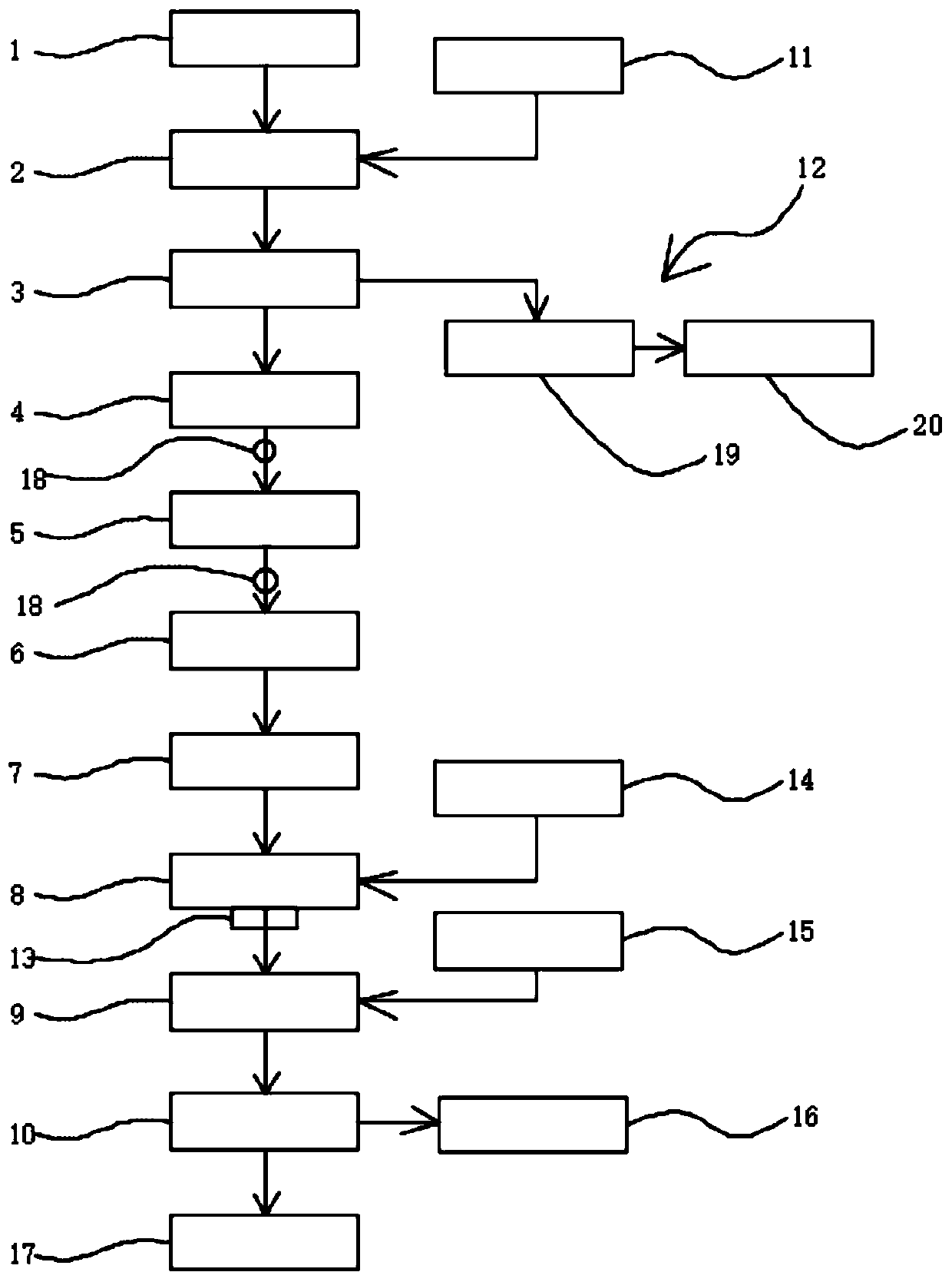

[0032] Examples:

[0033] A PTA recovery process in alkali reduction wastewater, the specific steps are as follows:

[0034] Step 1. The alkali reduction wastewater is transported to the alkali water collection tank (1), where it is collected for use, and the pH of the wastewater is 11-12;

[0035] Step 2. Transport the alkali reduction wastewater to the primary treatment tank (2), and add 5% of the activated carbon relative to the weight of the wastewater in the primary treatment tank (2), and stir for 30 minutes to adsorb impurities in the wastewater;

[0036] Step 3. Use a centrifugal pump (18) to transport the waste water in the primary treatment tank (2) to the first filter press (3). The waste water is pressed into the closed filter chamber formed by two adjacent filter plates, so that the filter cloth A pressure difference is formed on both sides to achieve filtration and separation; and the activated carbon is recovered to the activated carbon recovery tank (19) through the fi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap