Roller centrifugal layer inner circle temperature measurement device

A technology of temperature measurement device and centrifugal layer, applied in the field of inner circle temperature measurement device of centrifugal layer of roll, can solve the problems of limited measurement distance, few measurement points, short measurement time, etc., to achieve accurate measurement data, avoid human factors, The effect of many measuring points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

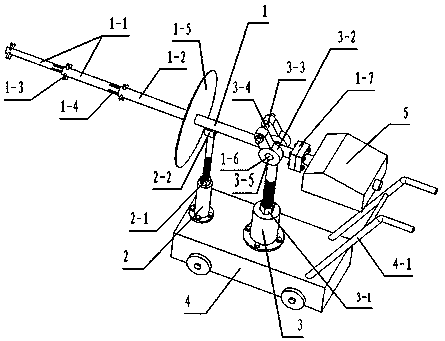

[0018] Below in conjunction with accompanying drawing, the present invention will be further described by examples.

[0019] Refer to attached figure 1 According to the present invention, before the centrifugal casting, according to the length of the roll, the telescopic gun rod 1-1 is determined to be 3 sections, and the temperature measuring thermocouple 1-3 is moved in the chute 1-4 by adjusting the telescopic gun rod 1-1 to evenly distribute 3 The distance between groups of thermocouples is set to 4 for each group of thermocouples to control the distribution and spacing of temperature measurement points. Then adjust the vertical height of the temperature measuring gun rod 1 through the front bracket height adjusting bolt 2-1 and the rear bracket height adjusting bolt 3-1 to ensure that the temperature measuring gun rod 1 is at the center of the centrifugal layer.

[0020] After centrifugal pouring for 10 minutes, you can hold the handrail 4-1 and push the temperature meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com