Real-time liquid level measurement and analysis method based on distributed optical fiber liquid level sensor

A technology of liquid level sensor and distributed optical fiber, which is applied in the direction of liquid/fluid solid measurement, measuring device, liquid level indicator, etc., can solve the problem that it is difficult to meet the demand for spatial resolution of liquid level measurement, and improve the measurement accuracy and coverage, fast response, and wide coverage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to make the object, technical solution and advantages of the present invention clearer, the embodiments disclosed in the present invention will be further described in detail below in conjunction with the accompanying drawings.

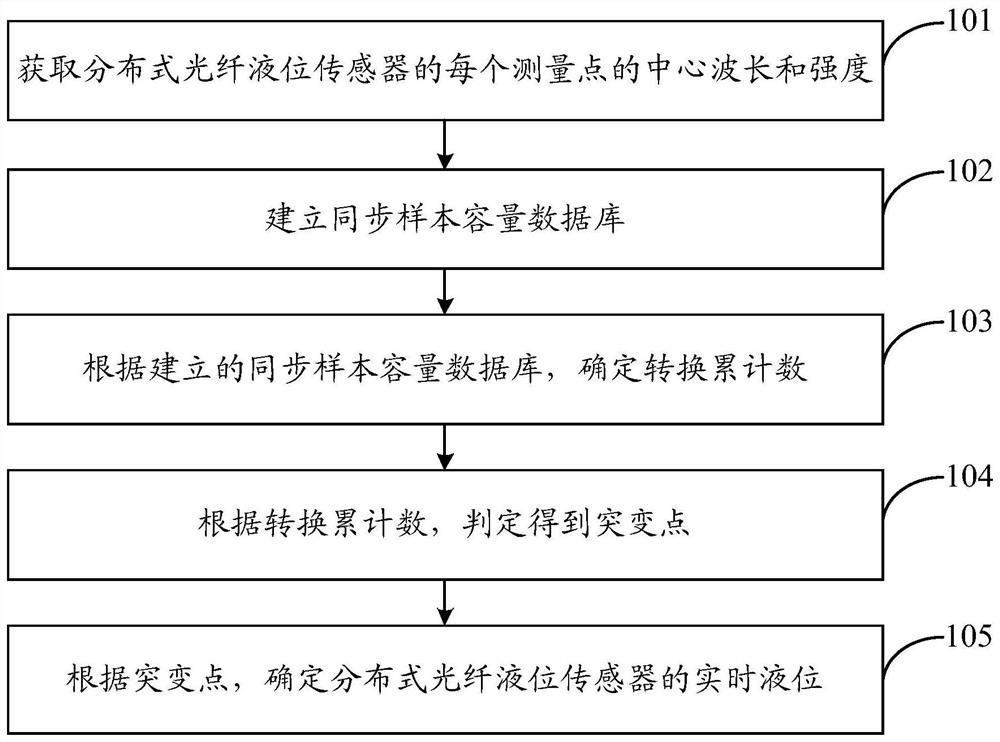

[0056] Such as figure 1 , in this embodiment, the real-time liquid level measurement and analysis method based on the distributed optical fiber liquid level sensor includes:

[0057] Step 101, acquire the central wavelength and intensity of each measurement point of the distributed optical fiber liquid level sensor.

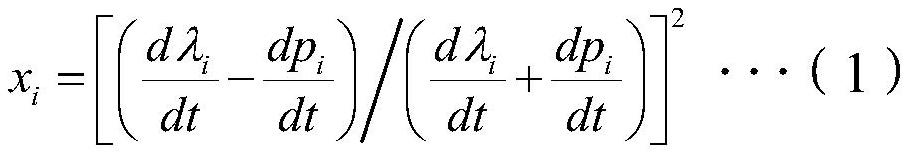

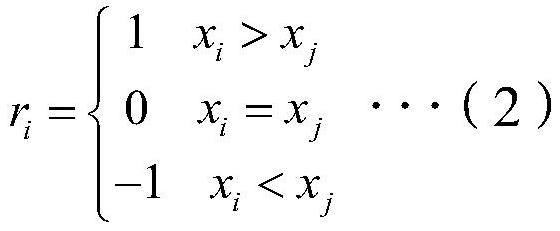

[0058] In this embodiment, the distributed optical fiber liquid level sensor may specifically refer to: a distributed optical fiber liquid level sensor in which long-period optical fiber gratings are written continuously, and each long-period optical fiber grating adopts an identical writing method. Further, the measurement point may specifically refer to: a long-period fiber grating. Among them, in different environmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com