Knitting needles, in particular for producing knitted articles with braided patterns, and method for producing knitting needles

A knitting and product technology, applied in the direction of knitting, weft knitting, hand tools, etc., can solve the problems of interference and inflexibility, achieve the effect of good connection, reliable and reliable connection, and minimize the risk of injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

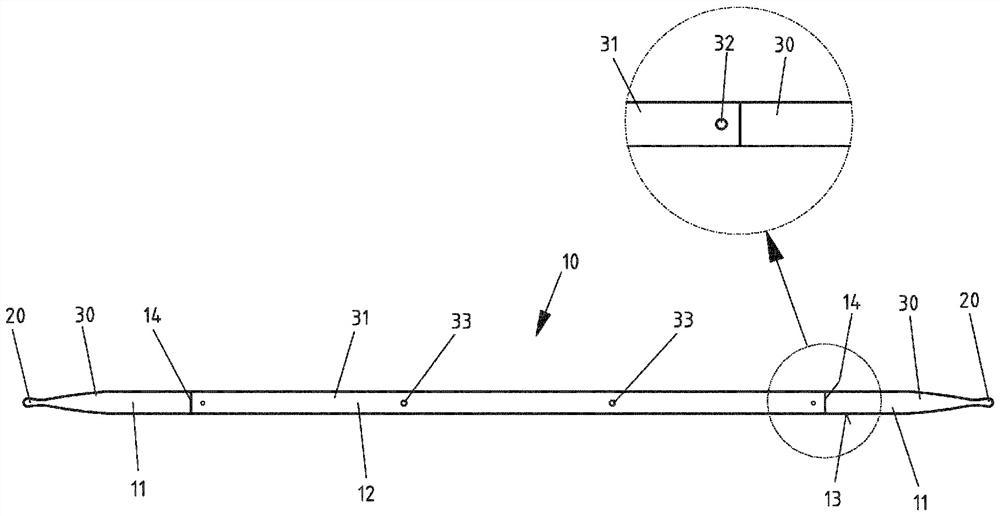

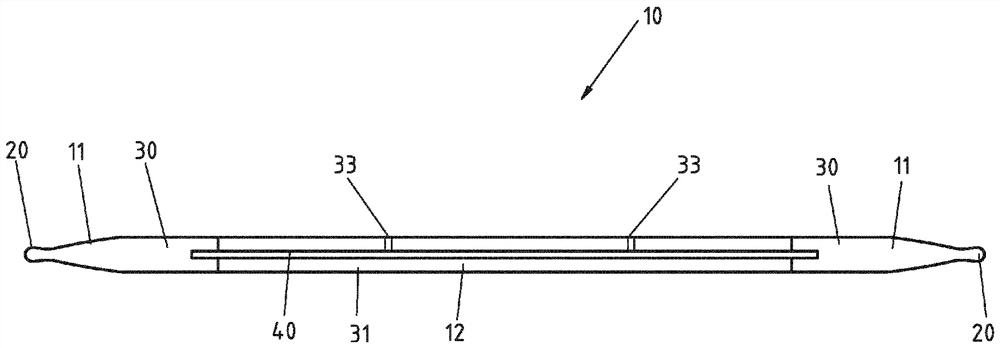

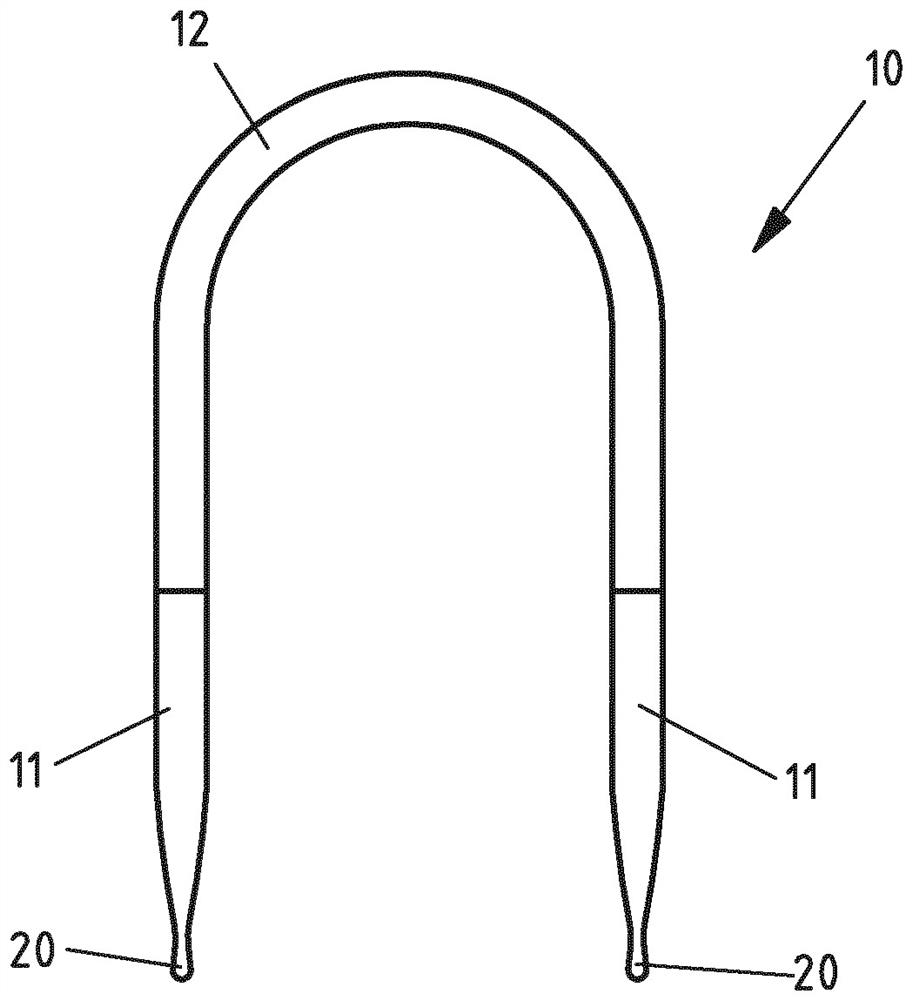

[0026] figure 1 A knitting needle 10 according to the invention is shown. The knitting needle has two needle points 11 made of a hard first plastic 30 . In the region of the shaft 12 a soft second plastic 31 is used. The transition 14 between the shank 12 and the needle point 11 is formed flush and smooth here, so that absolutely no protrusions and the like are produced which could be obstructive during the knitting process.

[0027] It can be seen in the enlarged view shown that the soft second plastic 31 also surrounds the hard first plastic 30 in the region of the injection points (Anspritzpunktes) 32 in order to create a particularly good connection between the two plastics 30 , 31 unbreakable connection.

[0028] In addition, rounded thickenings, ie reversing drops 20 , are each provided on the two needle tips 11 . The reversing drop minimizes the risk of injury so that the operator is not injured at the needle point 11 during the knitting process.

[0029] Figure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com