Pressure detection device of high-pressure casting machine

A detection device and high-pressure casting technology, which is applied in measuring devices, casting equipment, force/torque/work measuring instruments, etc., can solve the problems of not being able to display the working status of the pressure detection probe in real time, troublesome disassembly of the pressure detection probe, and low accuracy of detection data, etc. problem, to achieve the effect of good installation, good clamping effect and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

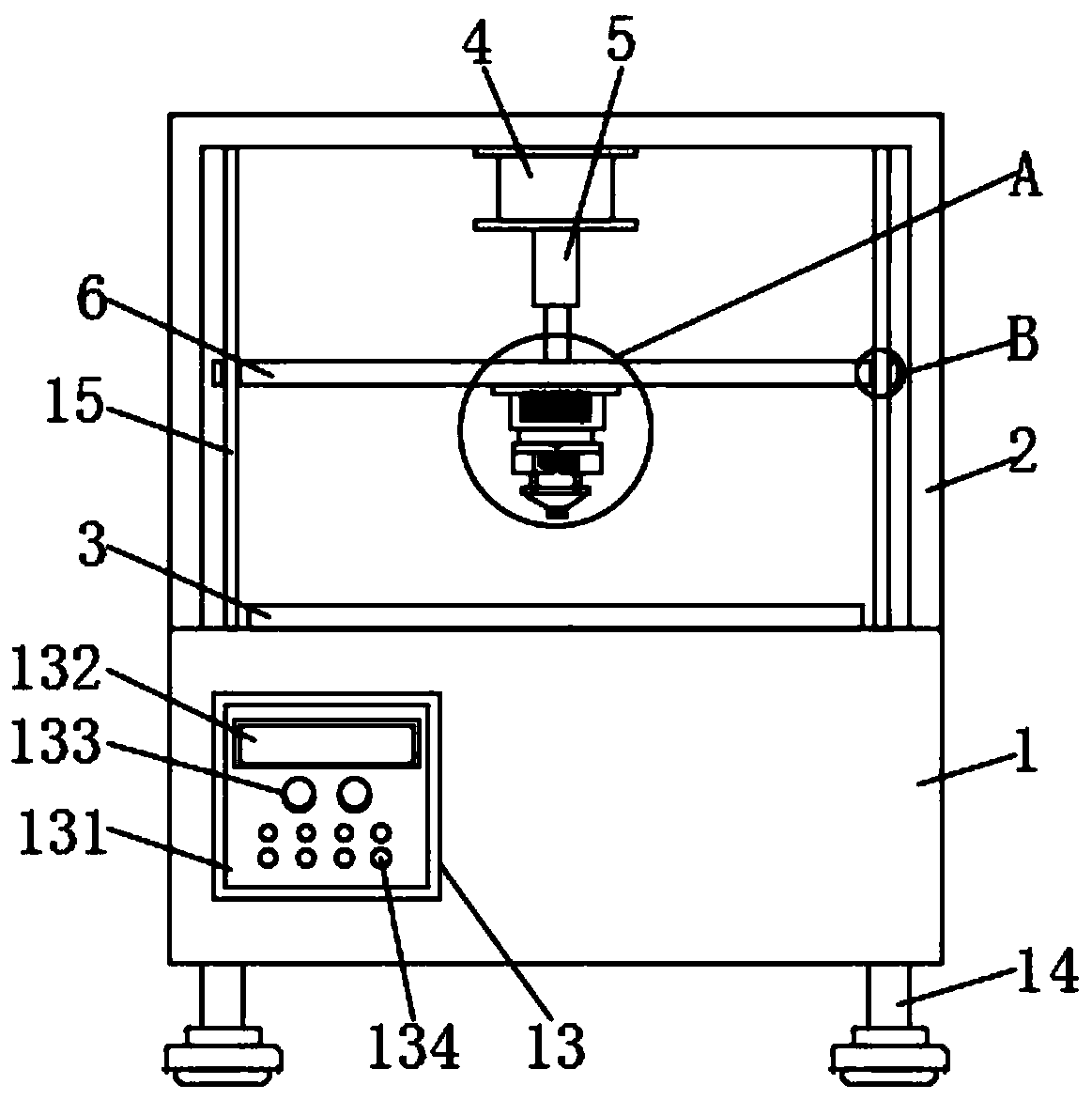

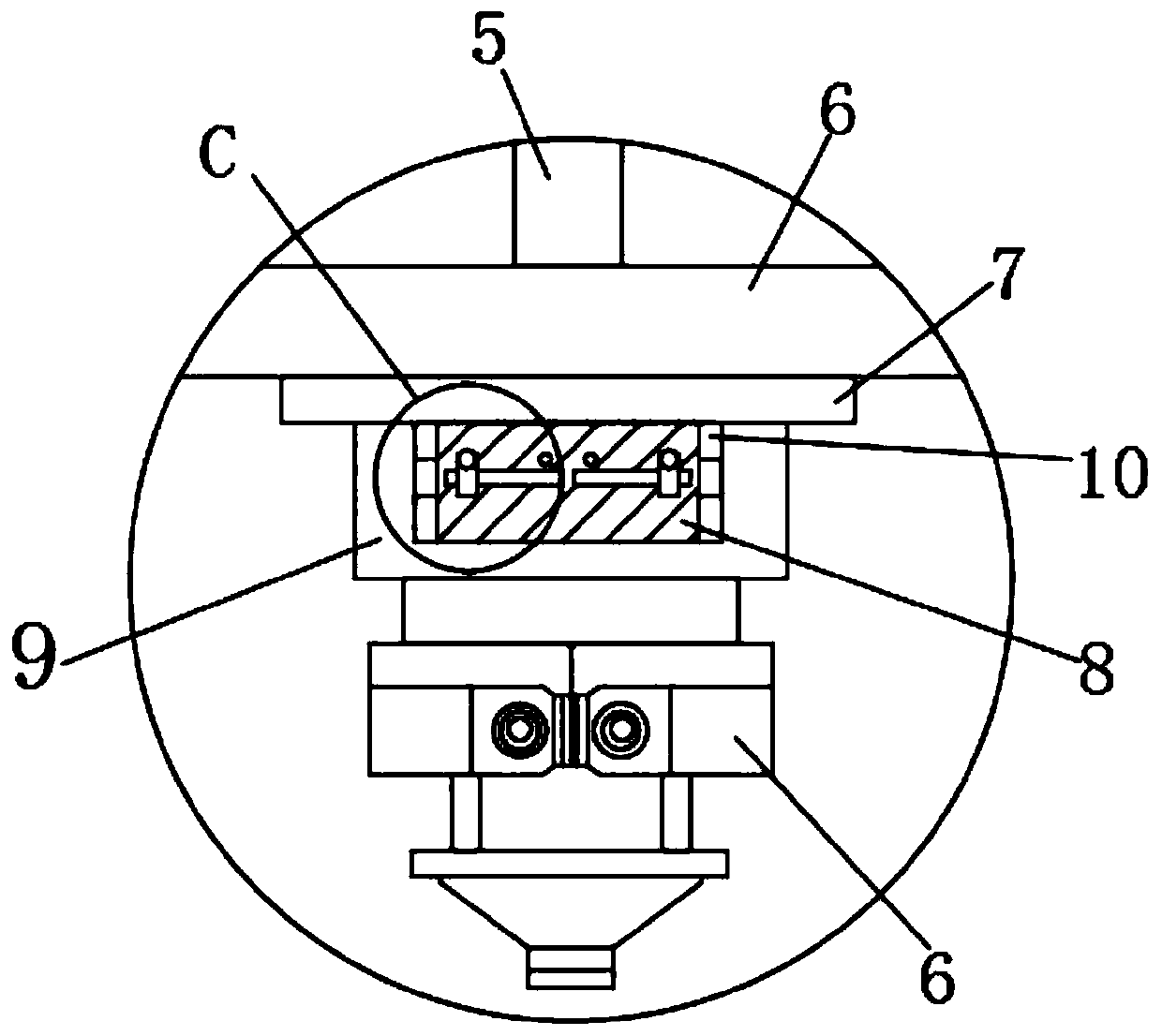

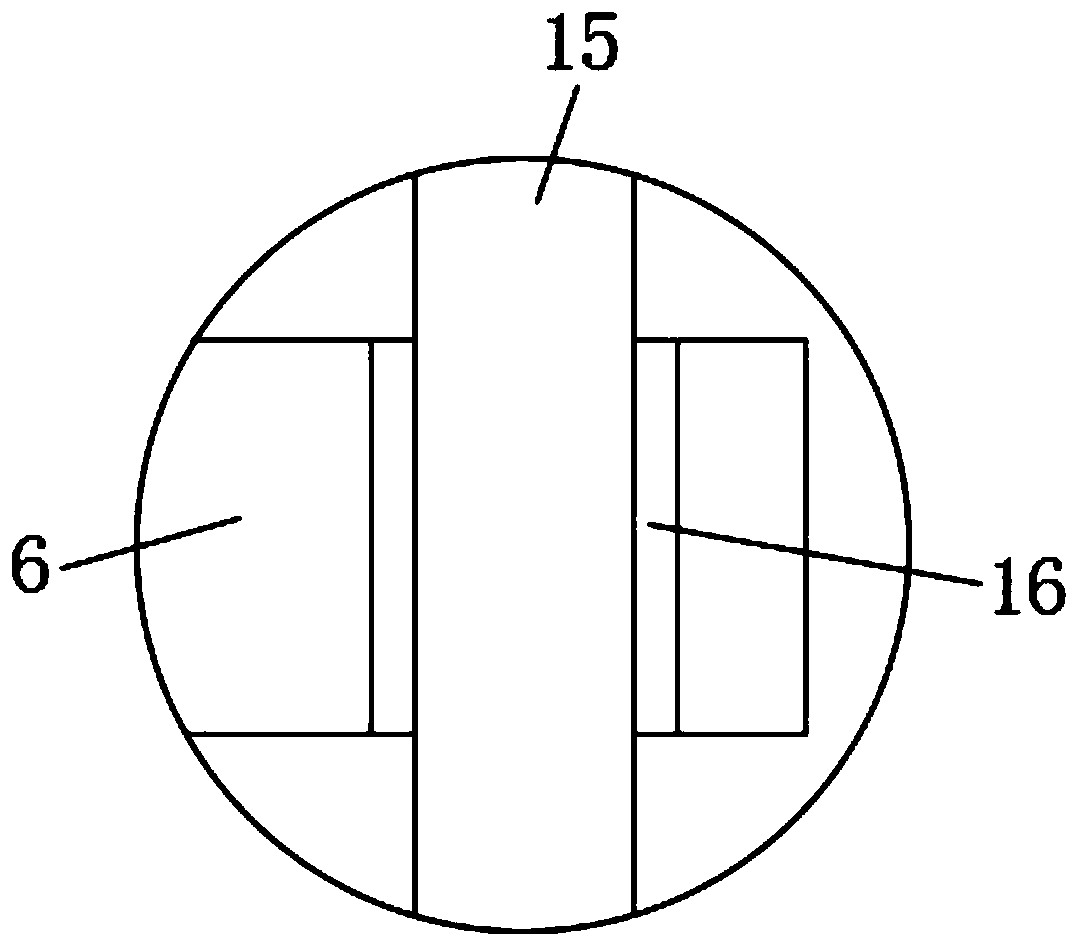

[0040] See Figure 1-8 , A pressure detection device for a high-pressure casting machine, comprising a detection table 1, the top of the detection table 1 is fixedly connected with a support frame 2, the top of the detection table 1 and located inside the support frame 2 is fixedly connected with a detection placement plate 3, a support frame 2 The inner top wall is fixedly connected with a hydraulic telescopic cylinder 4, the bottom of the hydraulic telescopic cylinder 4 is fixedly connected with a telescopic push rod 5, the bottom of the telescopic push rod 5 is fixedly connected with a movable push plate 6, and the bottom of the movable push plate 6 is fixedly connected with installation Plate 7, the bottom of the mounting plate 7 is provided with left and right retractable limiting devices 8, the bottom of the mounting plate 7 is provided with a connecting block 9, and the top of the connecting block 9 is provided with a placement slot 10, and the bottom of the left and righ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com