A fish plate processing technology

A processing technology and fishplate technology, which is applied in the field of fishplate processing technology, can solve the problems of increasing the number of turns of the fishplate blank plate in the processing workshop, complicated process steps, etc., so as to improve the turning efficiency, reduce the number of turns, The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0055] A fishplate processing technology, with reference to Figure 4 , which includes the following steps:

[0056] Cut off:

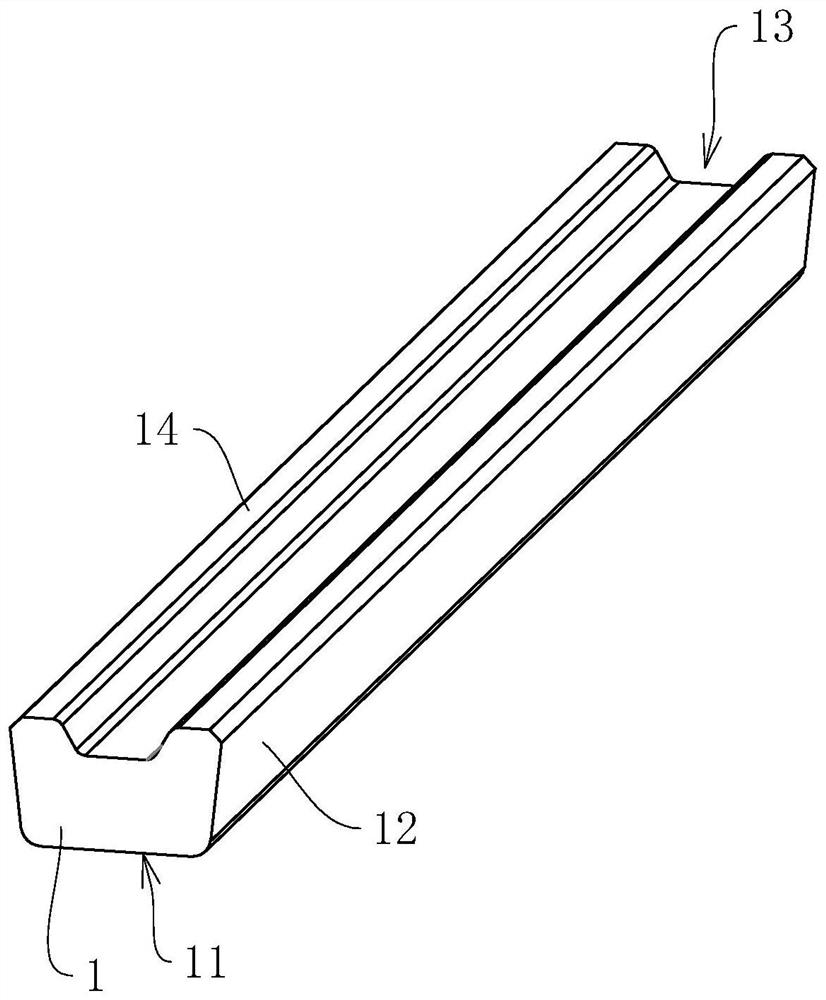

[0057] Cut the blank to obtain a fishtail slab 1 with a length of 835+2 mm, and the shape of the fishtail slab 1 is as follows figure 1 shown.

[0058] Milling face:

[0059] With the aid of a milling machine, turn and mill the cross-sections at both ends of the length direction of the cut fishtail slab 1 until it is smooth, and control the length of the fishtail slab 1 after turning and milling to be 835+1mm.

[0060] Milling large sides:

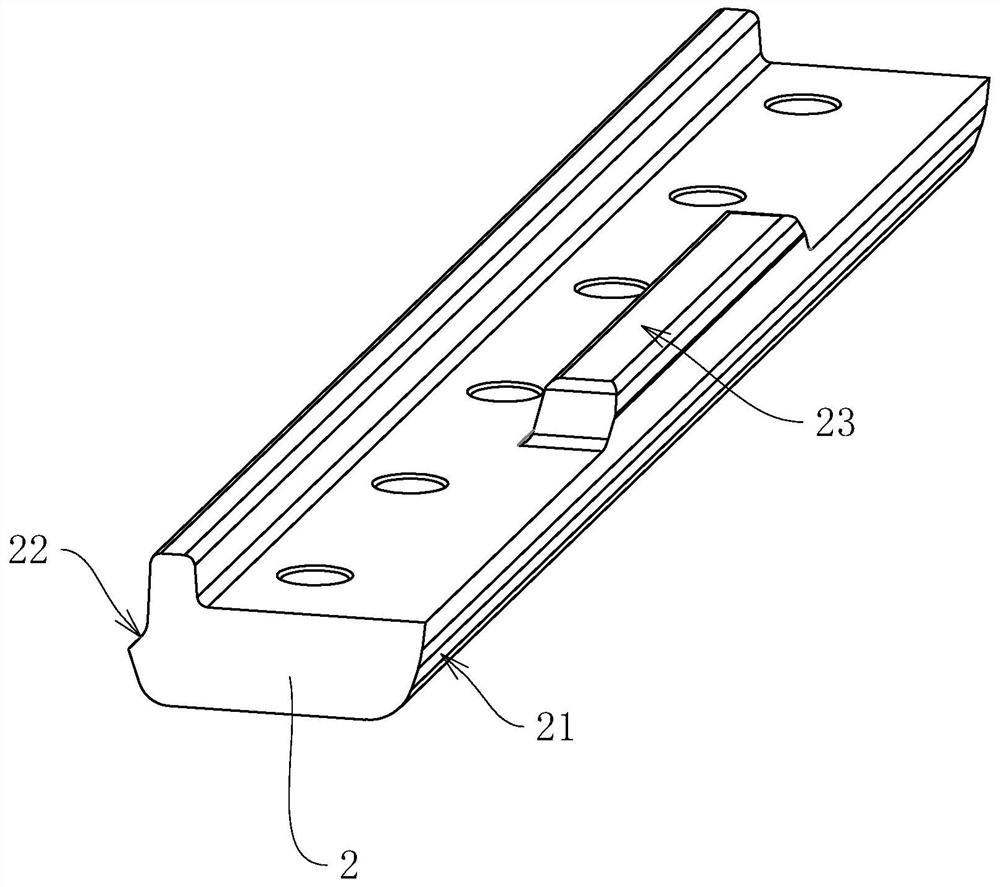

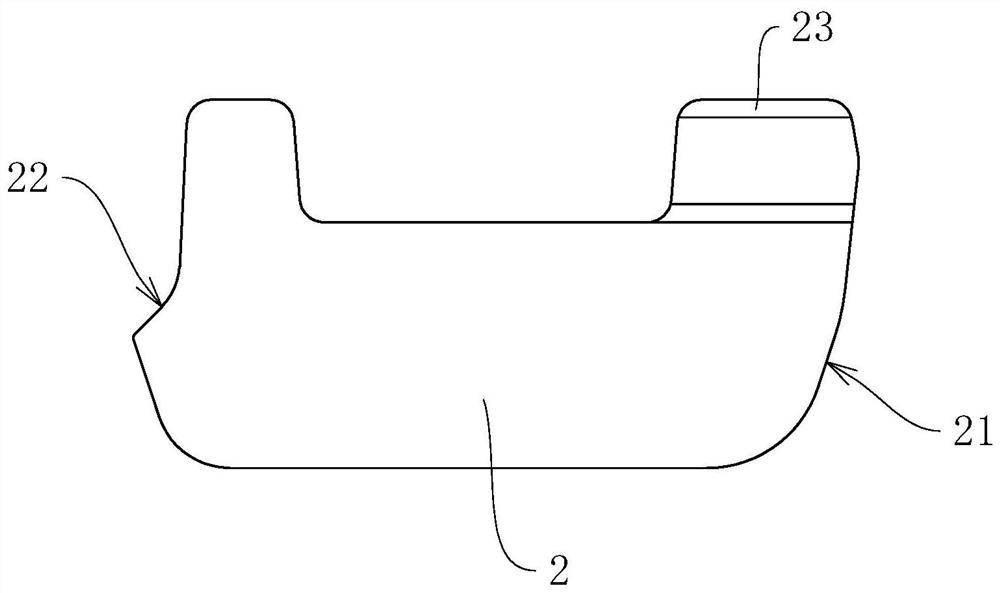

[0061] The first turning and milling equipment is used to simultaneously turn and mill the two sides 11 of the fishtail slab 1 that has been milled over the end face until the distance between the two sides 11 is 40±0.2mm.

[0062] refer to Figure 5 , the first turning and milling equipment includes a first workbench 3 , a first slab fixing tool set on the first workbench 3 , and first racks 31 symmetricall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap