Tension relax device and tension relax method

A driving device and tension rod technology, applied in ceramic molding machines, manufacturing tools, etc., can solve the problems of affecting the demoulding work of ballastless track slabs, high labor intensity of workers, affecting production costs, etc., and avoid manual secondary adjustment of tension. Pull rod, simple structure, and the effect of reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

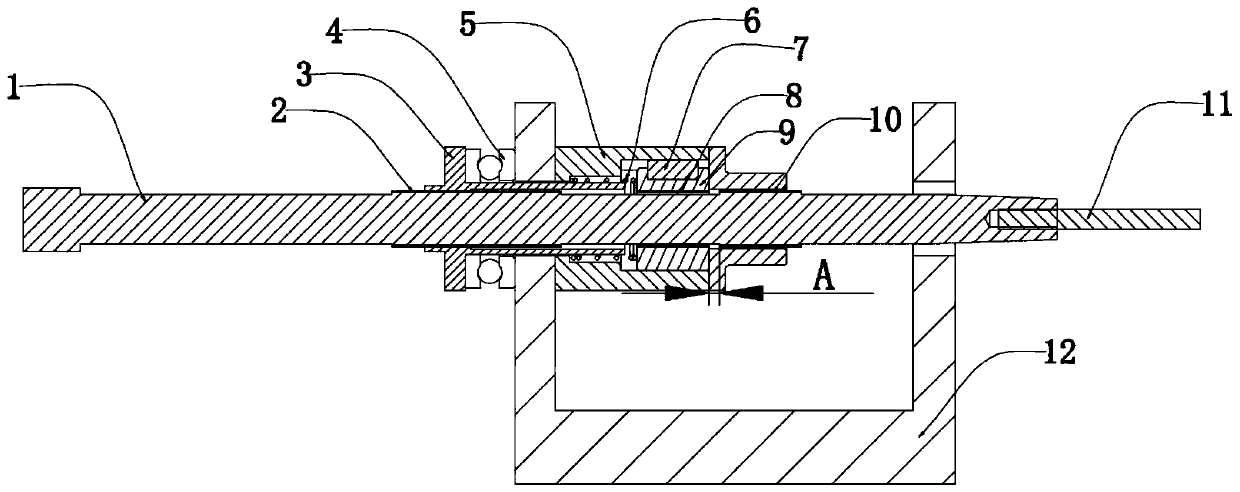

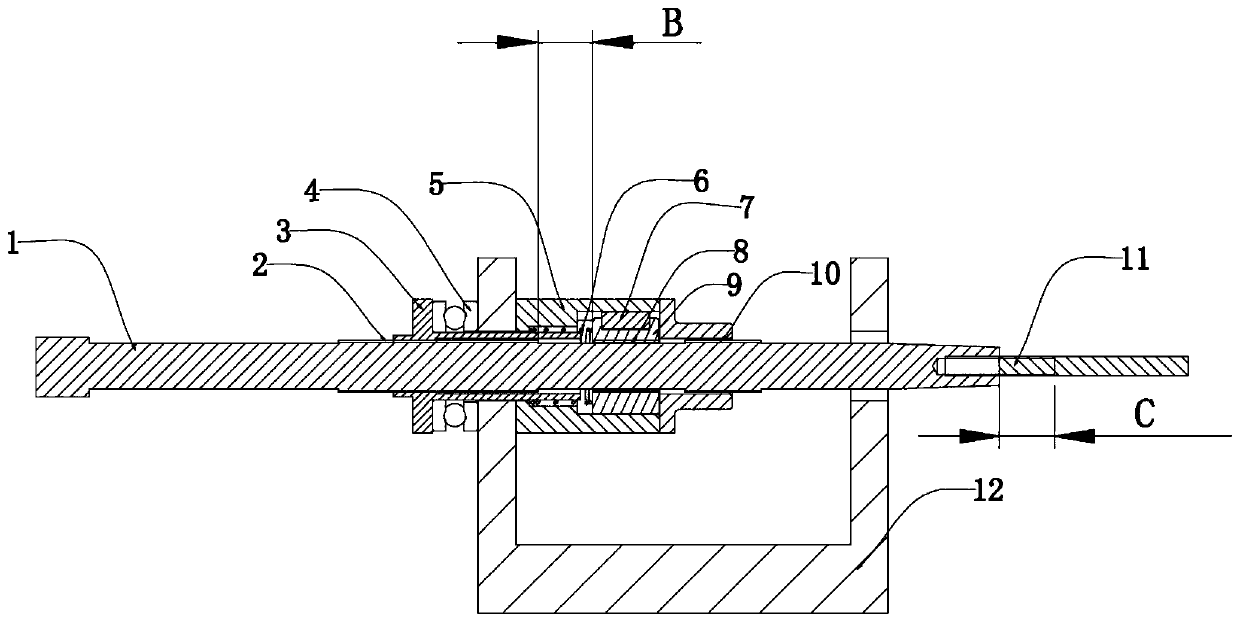

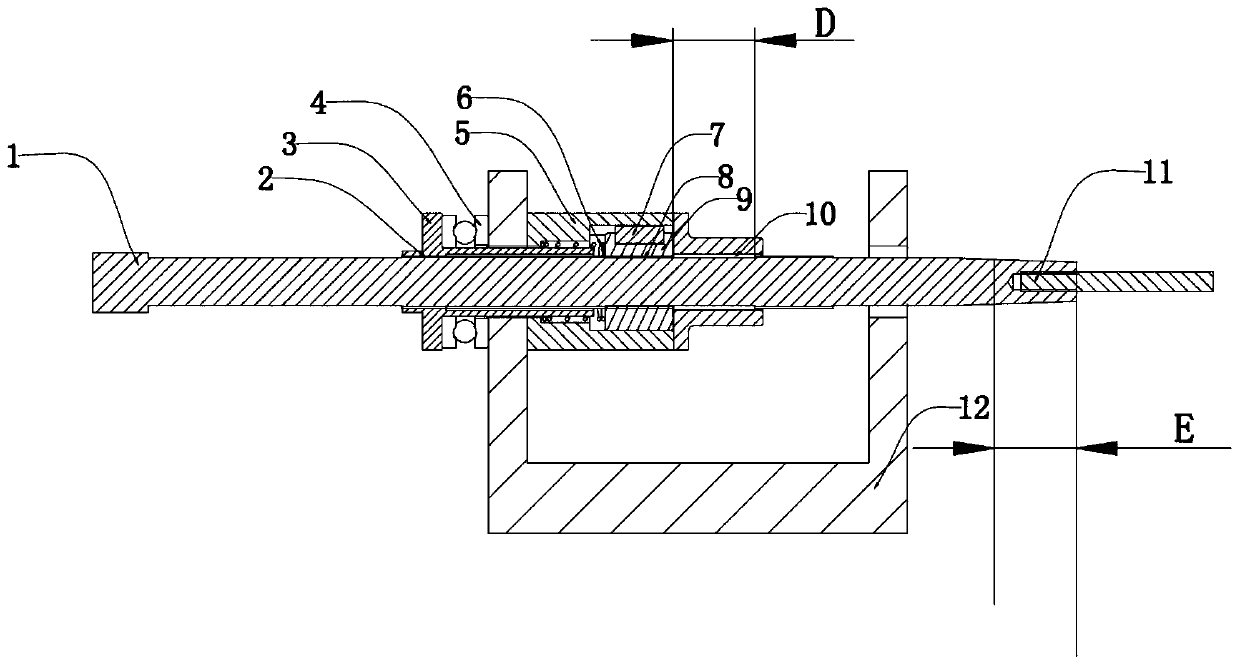

[0032] Please refer to Figure 1-3 , in this embodiment, the inner cavity of the guide seat 5 has a receiving cavity, and a retreat nut 9 is arranged in the receiving cavity, and a second screw thread 8 is provided on the inner cavity wall of the retracting nut 9; the tension rod 1 passes through the retracting Nut 9, during the retraction process of the tension rod 1, the side of the first thread 10 close to the second end will be threadedly connected with the second thread 8 on the retraction nut 9, so that the second thread of the tension rod 1 on the retraction nut 9 The thread 8 can be further retracted under the action of the thread, and finally the tension rod 1 is retracted outside the inner surface of the mould, avoiding manual secondary adjustment of the tension rod 1 .

[0033] On the basis of the above-mentioned embodiments, a guide key 7 is provided between the side wall of the retraction nut 9 and the accommodation cavity to prevent the rotation of the retraction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com