Warehouse of metal plate flexible production line

A flexible production line and material warehouse technology, applied in the field of storage material warehouse, can solve the problems that the fixed effect is not relatively stable, the inconvenience of conveying sheet metal parts, economic losses, etc., and achieve a simple structure, easy implementation, and high stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

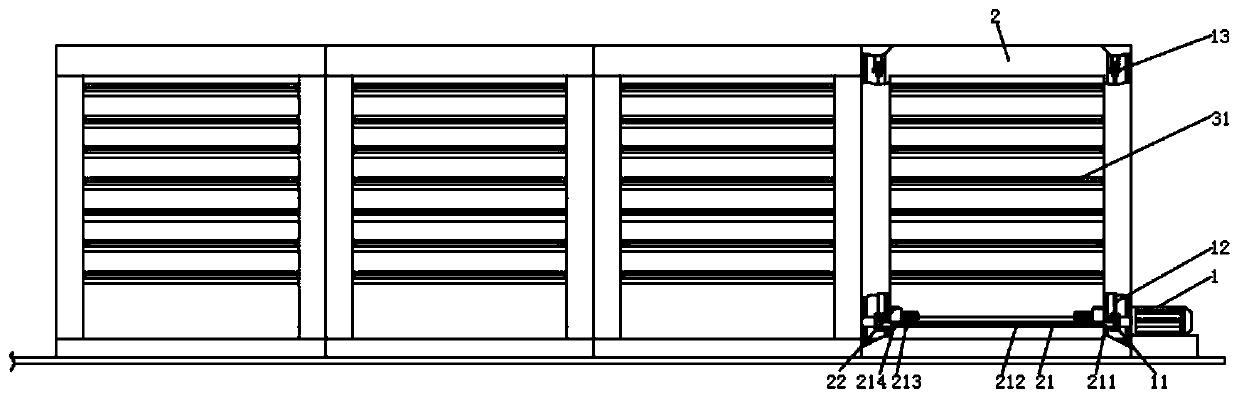

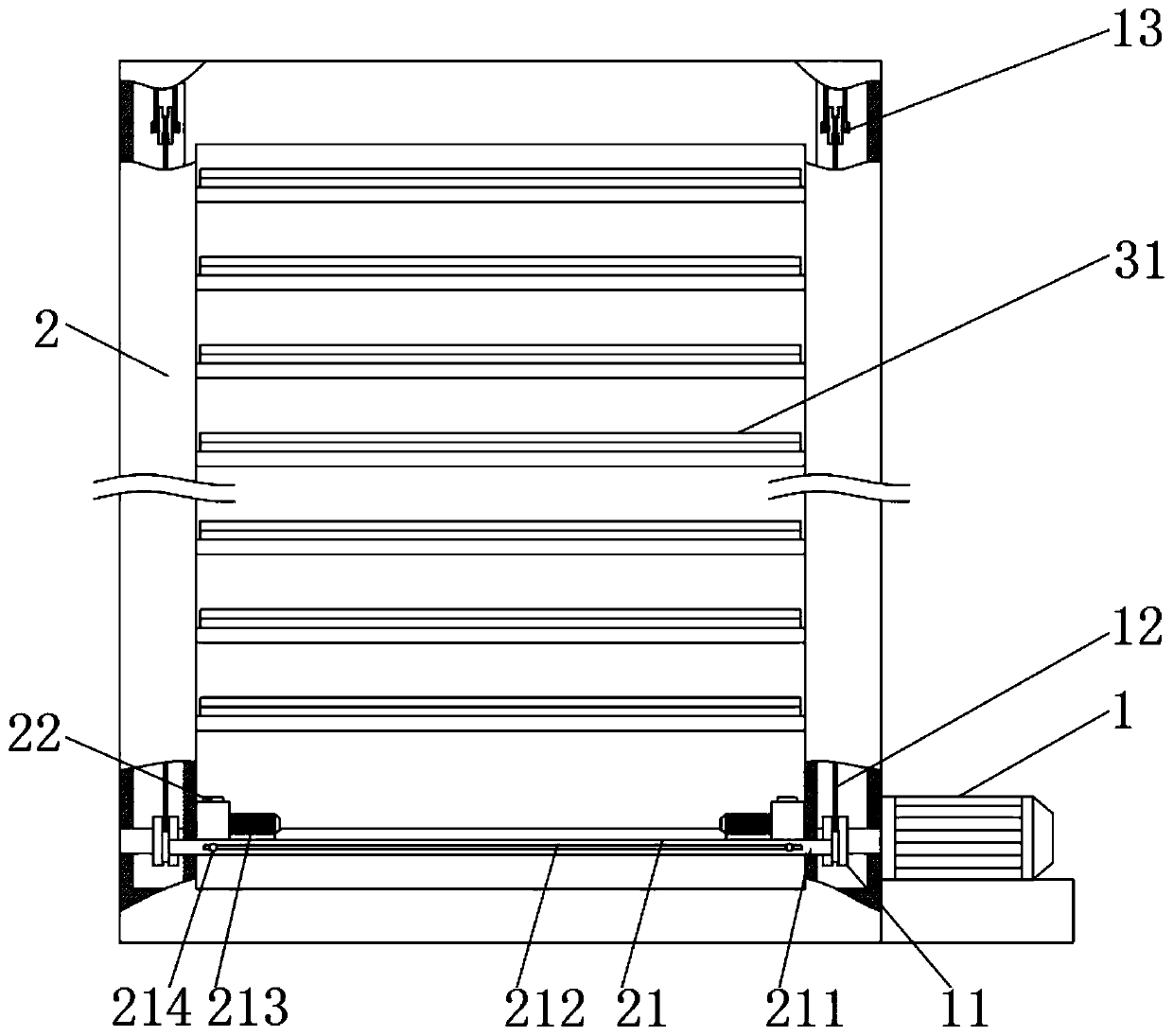

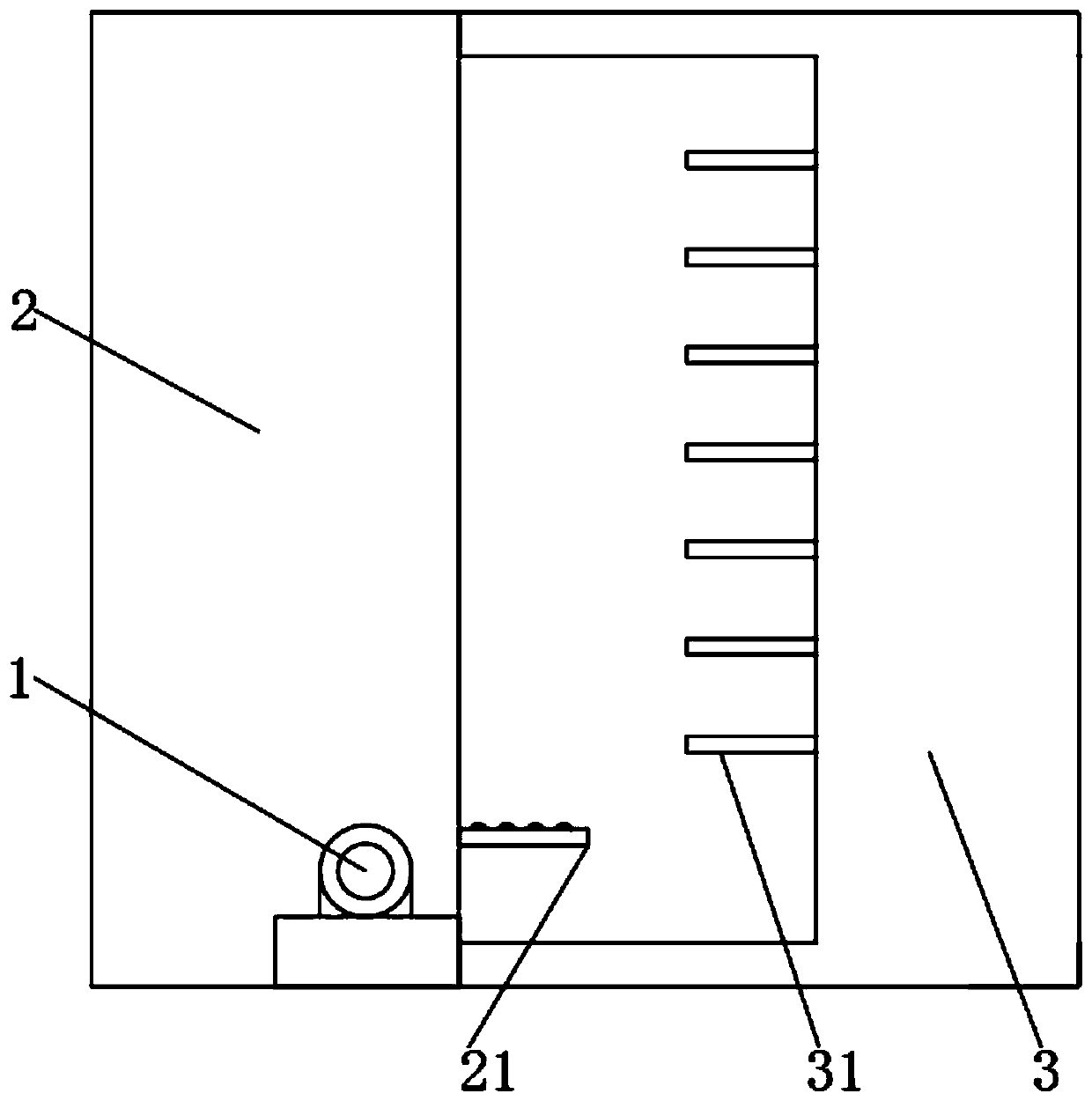

[0030] like Figure 1-6 As shown, a sheet metal flexible production line warehouse includes a sheet metal delivery part 2, a sheet metal storage part 3, a lifting drive mechanism 1 arranged on the sheet metal delivery part 2, and the sheet metal delivery part 2 includes a conveying Mechanism 21 and conveying plate 22, conveying mechanism 21 comprises horizontal plate 211, is located at the slide groove 212 on the horizontal plate 211, is located at the conveying motor 213 on the horizontal plate 211, is located at the sliding stop block 215 in the sliding groove 212 and Fix the bolt 214, the sliding limit block 215 is fixedly connected with the conveying plate 22, the output shaft of the conveying motor 213 runs through the conveying plate 22; On the shaft, a rotating shaft runs through the driven wheel 225, a gear 223 is installed on the output shaft and the rotating shaft of the conveying motor 213, and a chain 224 is engaged on the gear 223; the sheet metal storage part 3 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com