Mounting structure of rotating disc surface aerator for cylindrical tank

A technology of surface aerator and installation structure, which is applied in water aeration, sustainable biological treatment, water/sludge/sewage treatment, etc., to achieve the effect of easy production, simple structure and improved aeration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

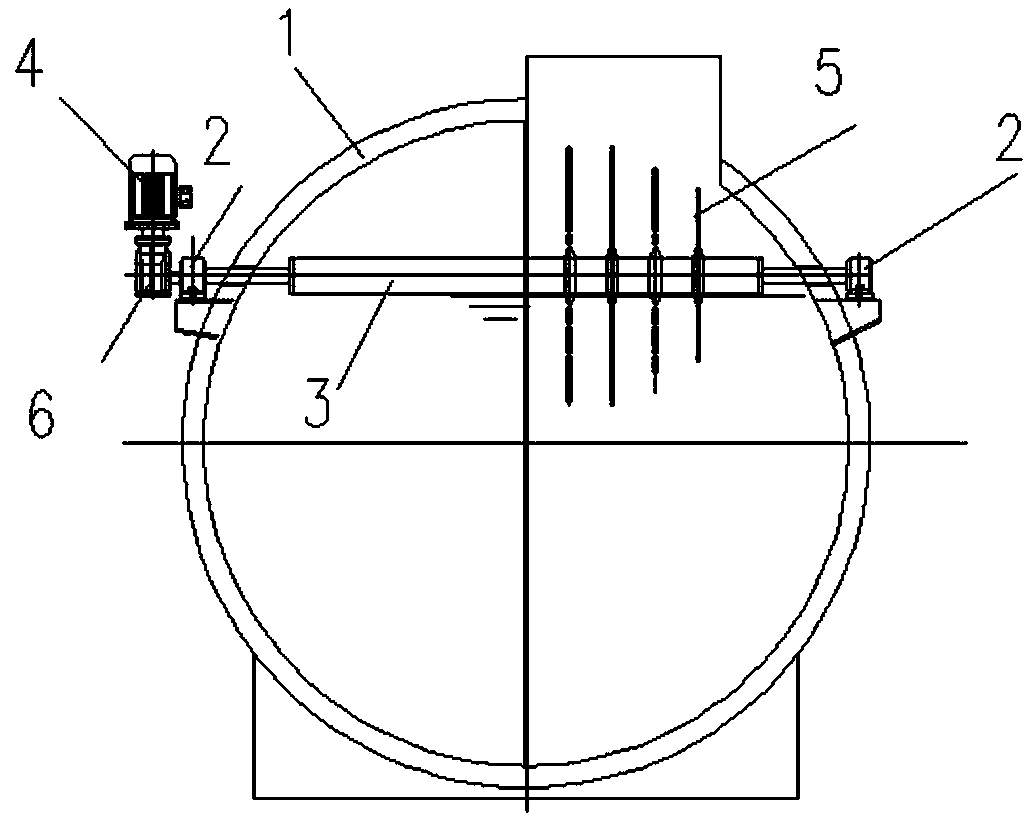

[0011] Embodiment 1: as figure 1 As shown in the figure, an installation structure of a rotating disc surface aerator for a cylindrical tank body includes bearing housings 2 fixed on both sides of the tank body 1 wall, a rotating shaft 3 pierced in the tank body 1, and a reducer 6 . A variable frequency drive motor 4 capable of reversing forward and reverse. The two ends of the rotating shaft 3 pass through the wall of the tank body 1 and are installed in the bearing seat 2. The driving end of the rotating shaft 3 passes through the bearing seat 2 and is connected to the main shaft of the driving motor 4. 4 The groups of rotating discs 5 are sleeved on the rotating shaft 3 at intervals, and the outer diameter of each group of rotating discs 5 decreases gradually from the inside to the outside along with the height of the section of the tank body 1, forming a stepped shape.

[0012] Every group of rotating disks 5 is made up of a piece of rotating disks, and the size of rotatin...

Embodiment 2

[0013] Embodiment 2, with reference to Embodiment 1, other features remain unchanged, consists of 2 groups of rotating discs, each group of rotating discs is composed of two rotating discs, the size of the rotating discs is 1200mm, 1200mm, 800mm, 800mm. The distance between adjacent discs is 250mm~300mm.

Embodiment 3

[0014] Embodiment 3: With reference to Embodiment 1, other features remain unchanged. It consists of 2 groups of rotating discs. The first group of rotating discs is composed of three rotating discs. The size of the rotating discs is 1000mm. The second group of rotating discs consists of one rotating Composed of discs, the size of the rotating disc is 800mm. The distance between adjacent discs is 250mm~300mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap