Uniform gas flow distribution device of pulverized coal gasification burner

A technology of uniform air distribution and flow guide device, which is applied in the direction of granular/powdered fuel gasification, gasification process, petroleum industry, etc. It can solve the problems of furnace overheating, partial burning, etc., and achieve the elimination of violent disturbance and small pressure loss , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to illustrate the present invention more clearly, further description will be made below in conjunction with the accompanying drawings and specific embodiments. The content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

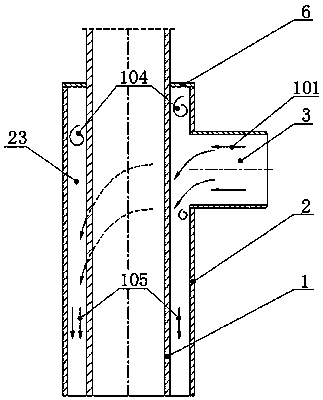

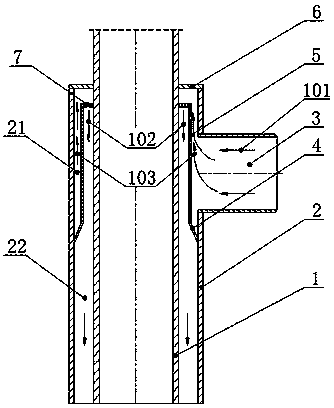

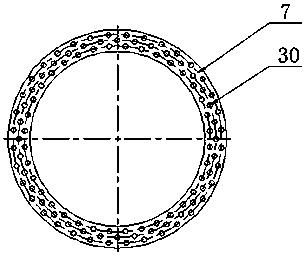

[0016] like Figure 1~3 As shown, the pulverized coal gasification burner gas distribution device provided by the present invention includes at least one air inlet 3 , an inner tube 1 , an outer tube 2 , and a top end cover 6 . A flow guiding device is arranged between the inner tube and the outer tube. The deflector includes a variable diameter tube 4, a deflector ring 5 and an air distribution plate 7, the upper port of the variable diameter tube is connected to the deflector ring, the lower port of the variable diameter tube is fixed on the inner wall of the outer tube, and the inner and outer diameters of the air distribution plate They are respect...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap