Anti-punching oblique anchor bolt

A punching-resistance, oblique technology, applied in the direction of construction, building structure, building material processing, etc., can solve the problem that the force cannot be fully exerted, and achieve the effect of simple structure, easy installation and control, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with specific examples and accompanying drawings. It should be noted that the following examples are limited to explain the present invention, but do not limit the implementation scope of the present invention. All structural additions made on the basis of this program or replacements with the same content all should belong to the protection scope of the present invention.

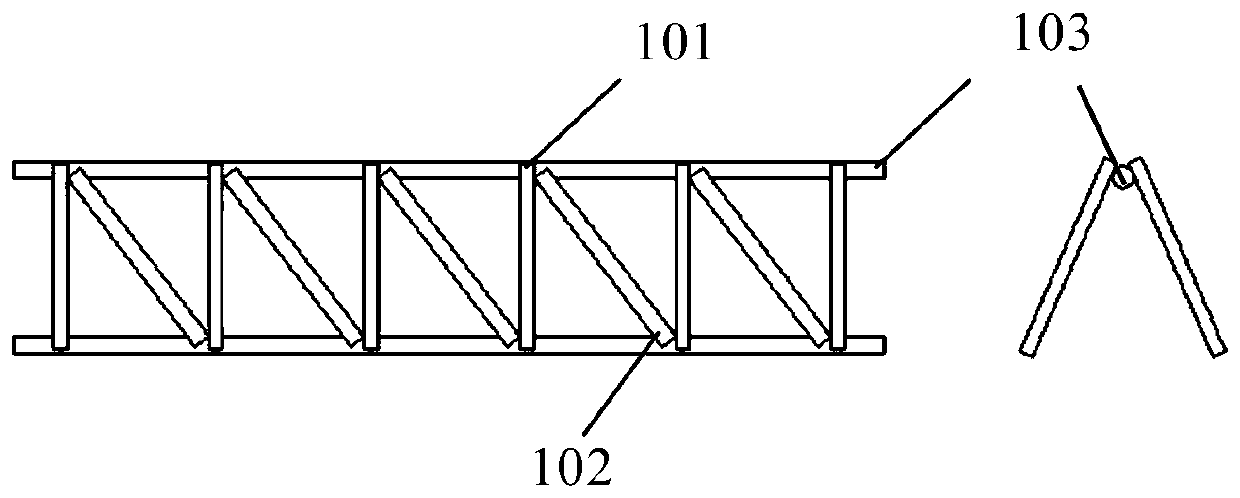

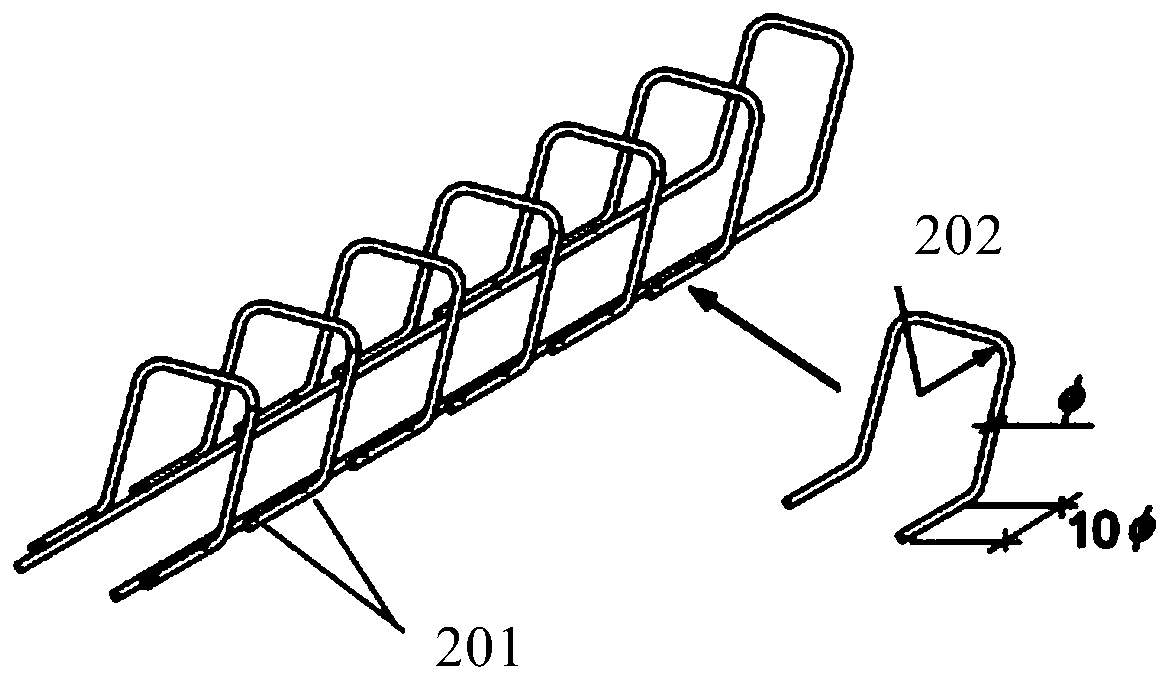

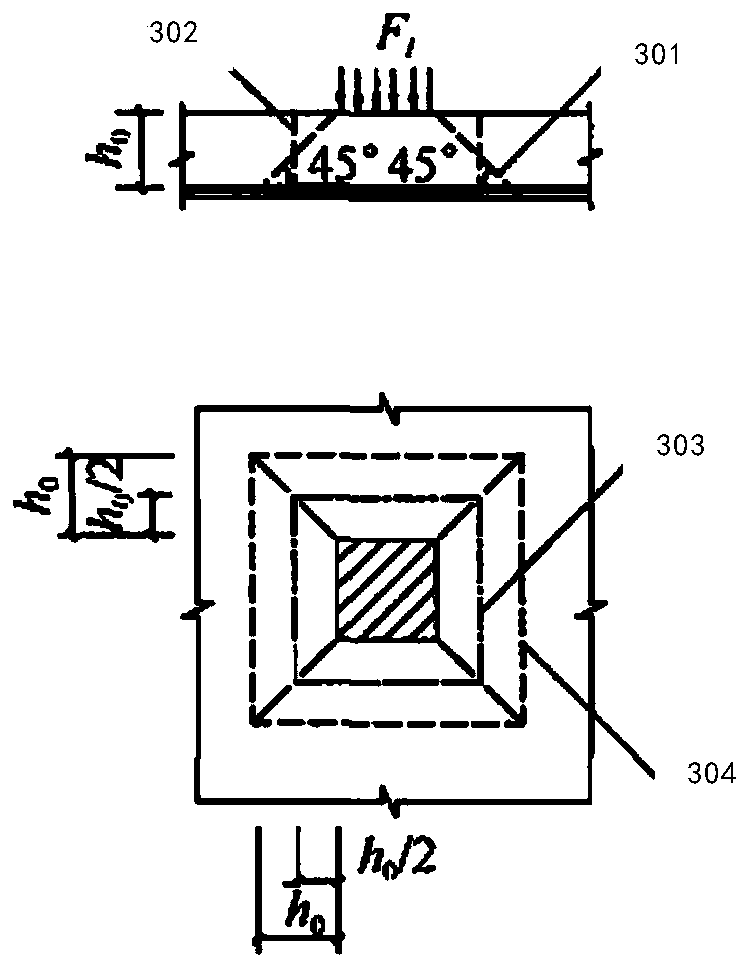

[0033] Such as Figure 5 As shown, the punching shear oblique anchor bolt is welded by the top anchor plate 1, the oblique steel bar 2 and the bottom anchor band 3. Top anchor plate 1 is positioned at the upper end, and middle part steel bar 2 is placed obliquely, becomes 45 ° angle with bottom anchor band 3, and bottom is used for fixing anchor bolt by bottom anchor band 3 and makes it arrange in groups.

[0034] The anti-punching shear oblique anchor bolt of the present invention is designed as an integrated structure, that is,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com